Furnace nose humidifier rectification method

A technology for humidifiers and furnace noses, applied in metal material coating process, hot-dip plating process, coating, etc., can solve problems such as poor humidification effect, and achieve the effect of improving humidification efficiency, better effect and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

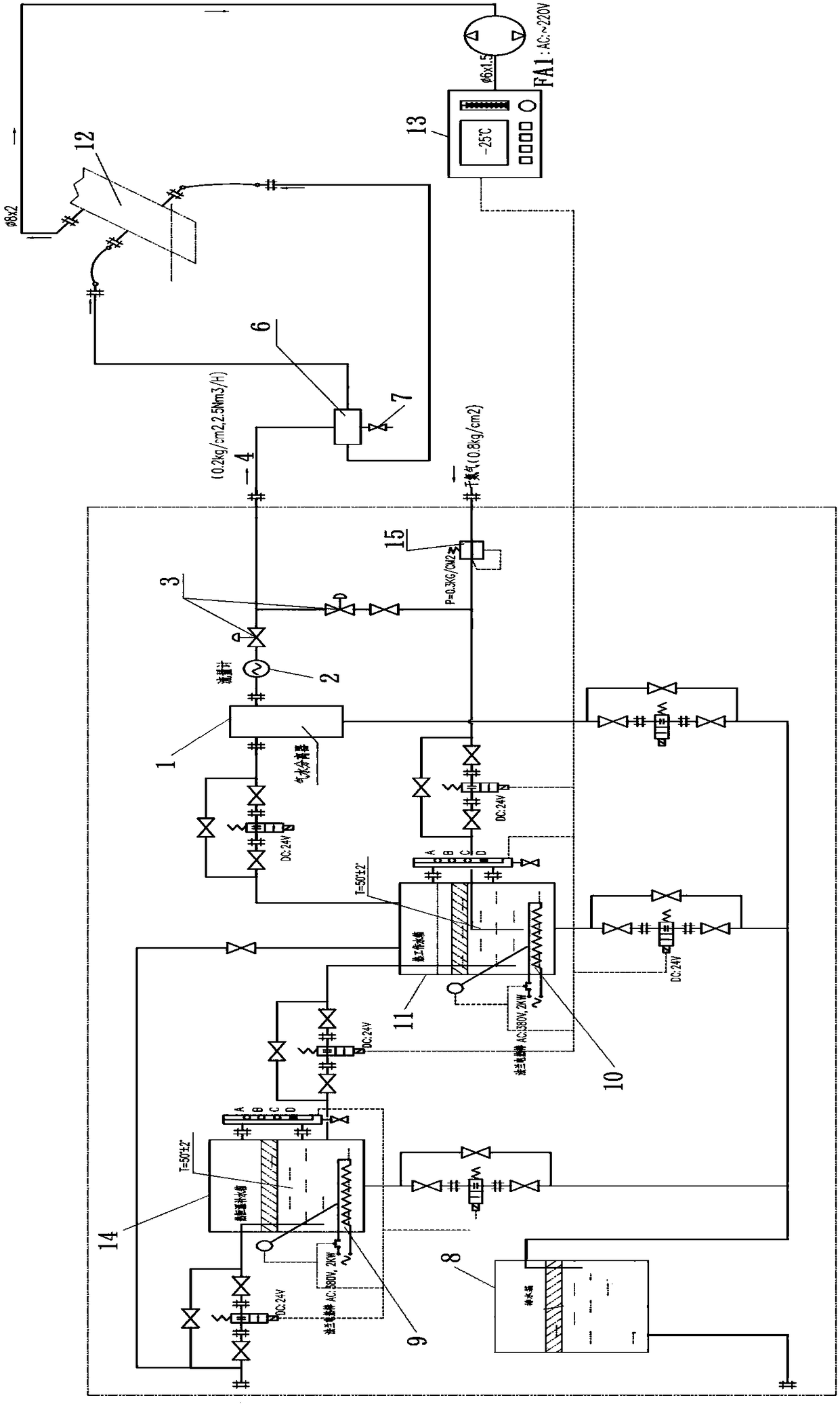

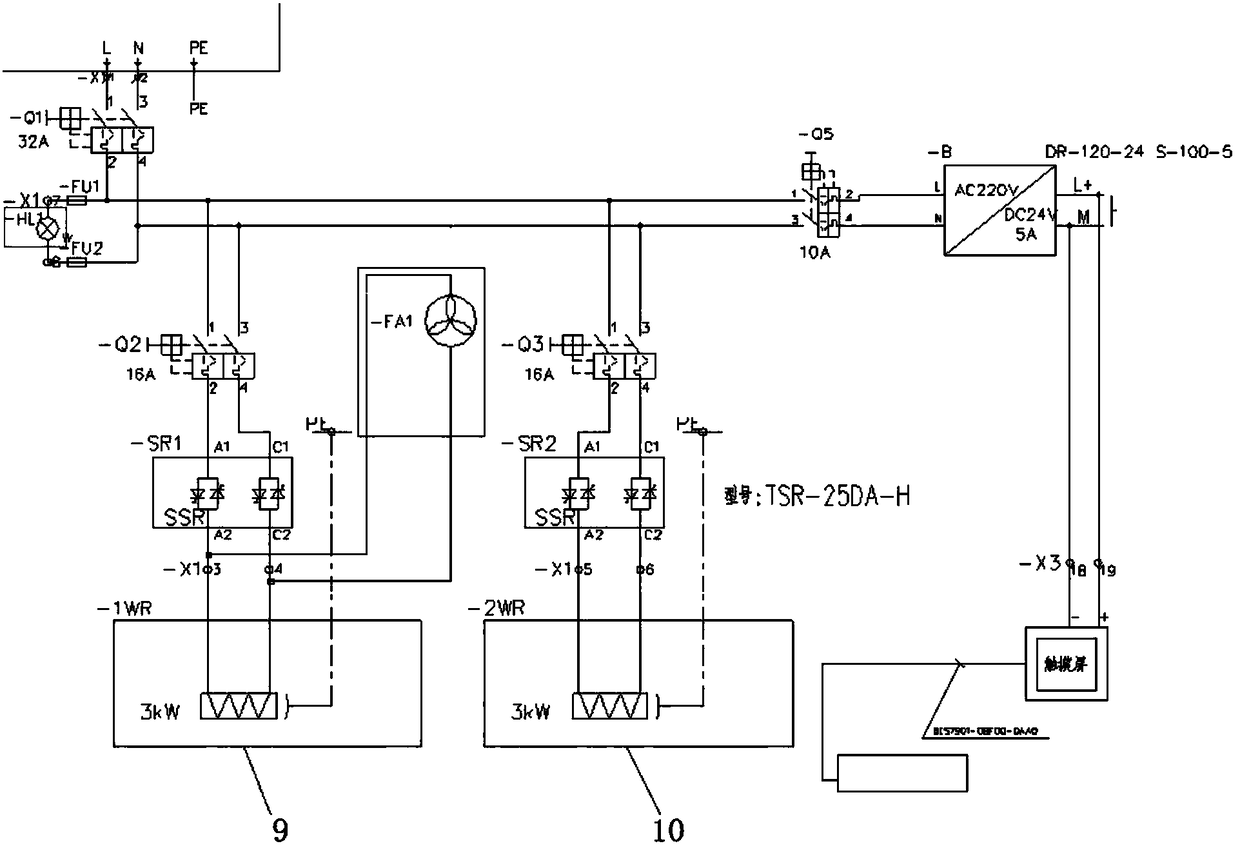

[0025] A rectification method for a furnace nose humidifier of the present invention comprises the following steps:

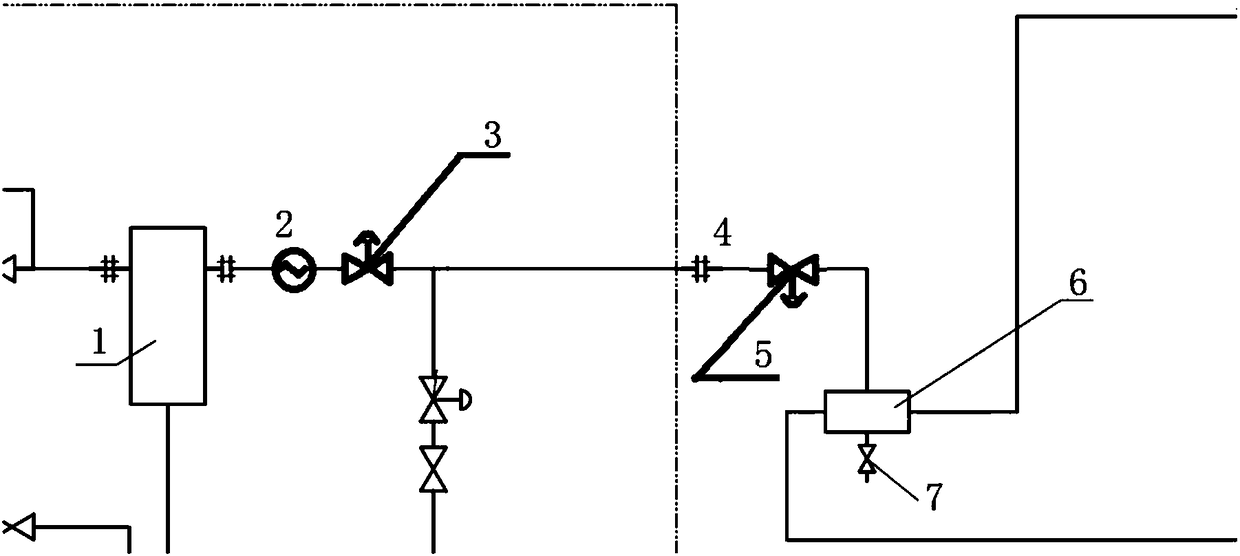

[0026] Install a drainage tank in the original furnace nose humidifier pipeline, so that the water in the gas-water separator can be discharged at the first time;

[0027] Improve the working air tightness of the air pump, and optimize the control circuit of the air pump to avoid zinc ash inhalation during maintenance and shutdown;

[0028] Improve the inlet pipe joint of the pressure reducing valve to ensure that the nitrogen pressure is between 0.02MPa and 0.04MPa to avoid pressure fluctuations and waste of nitrogen;

[0029] Optimize the water filling parameters of the water tank, enter a small amount of water multiple times, avoid a sudden drop in the temperature of the working water tank and adjust the working temperature to reach the required dew point value.

[0030] Such as figure 1 As shown, the present invention adds a drainage box to the original p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com