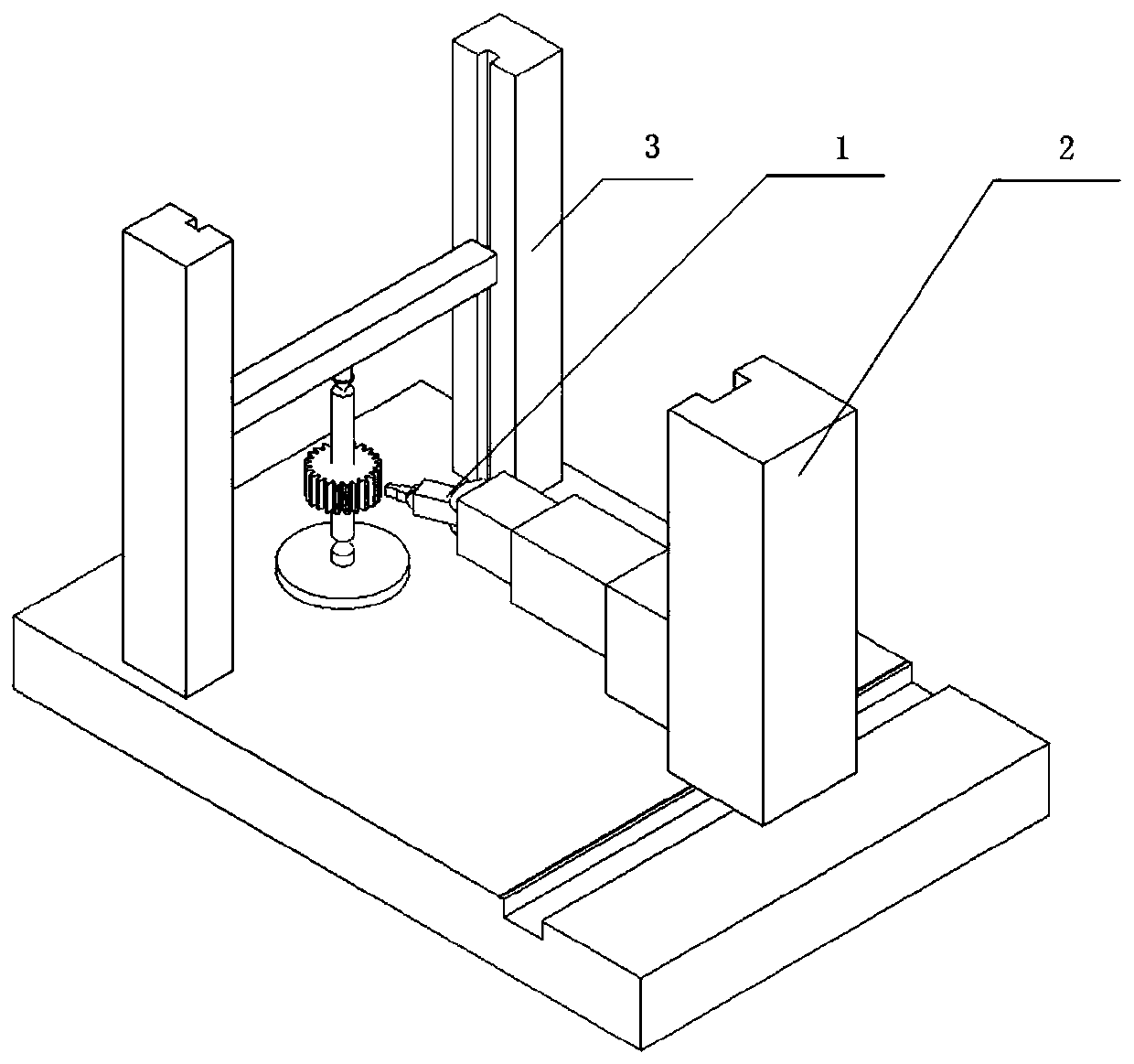

A six-axis laser gear measuring device

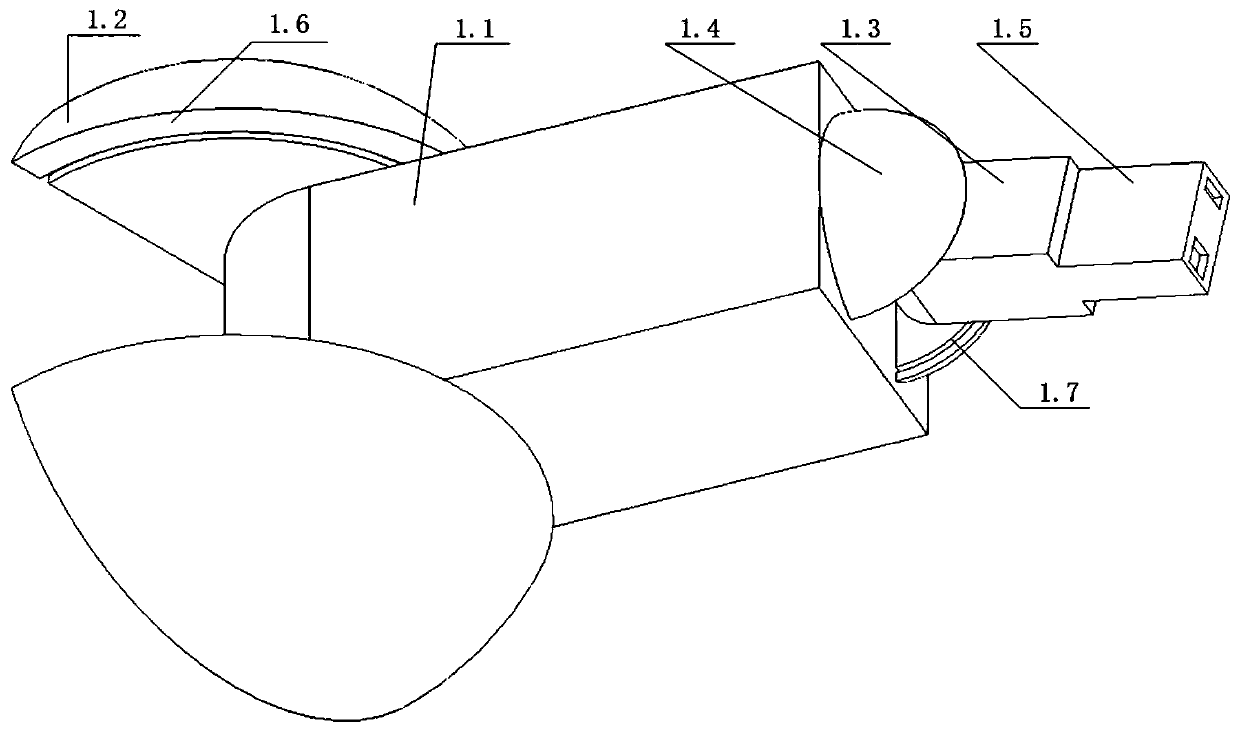

A gear measurement, six-axis technology, applied in the direction of measuring devices, optical devices, radio wave measurement systems, etc., can solve the problems that the detector cannot receive reflected light, can not effectively obtain data, and the measurement speed is slow, so as to overcome the radius Compensation, avoiding the problem of measuring dead angle, and improving the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

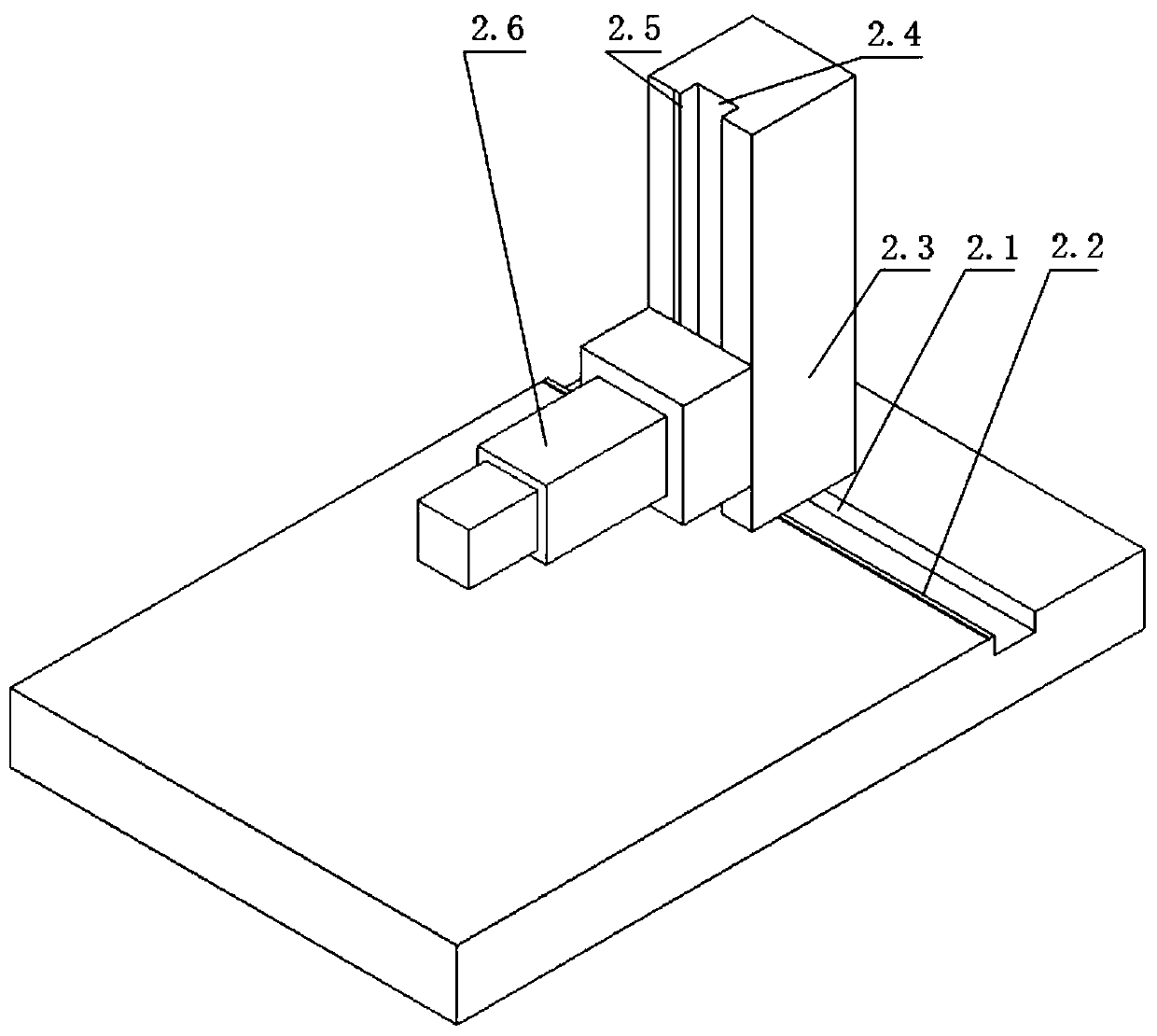

[0045] Such as Figure 5 As shown, the specific implementation of the cylindrical spur gear measurement using the present invention is realized through the following steps.

[0046] The first step is to reset the system. The six-axis movement is driven by the control system to drive the servo motor. The linear movement of the X-axis drives the Y, Z, α, and β-axis to move forward and backward along the X-axis, and the up-and-down movement of the Y-axis drives the Z, α, and β-axis to move up and down along the Y-axis. , the telescopic movement of the Z axis drives the α and β axes to move back and forth along the Z axis, and the rotation of the α axis drives the β axis to rotate around the α axis. The six-axis coordinate information is obtained through the grating signal corresponding to each axis, the six-axis reset is realized, and the coordinate system corresponding to the motion system is found.

[0047] The second step is to install the gears. Connect the cylindrical spu...

Embodiment 2

[0053] Such as Image 6 As shown, the specific implementation of bevel gear measurement using the present invention is realized through the following steps.

[0054] The first step is to reset the system. The servo motor is driven by the control system to operate the six-axis movement. The linear movement of the X-axis drives the Y, Z, α, and β-axis to move forward and backward along the X-axis, and the up-and-down movement of the Y-axis drives the Z, α, and β-axis to move up and down along the Y-axis. , the telescopic movement of the Z axis drives the α and β axes to move back and forth along the Z axis, and the rotation of the α axis drives the β axis to rotate around the α axis. The six-axis coordinate information is obtained through the grating signal corresponding to each axis, the six-axis reset is realized, and the coordinate system corresponding to the motion system is found.

[0055] The second step is to install the gears. Connect the bevel gear to be tested with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com