Preparation method and product of a calibration-free serial fiber grating temperature sensor

A temperature sensor, fiber grating technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of complex process, low efficiency, long time, etc., to achieve controllable degree of relaxation, batch consistency, batch good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

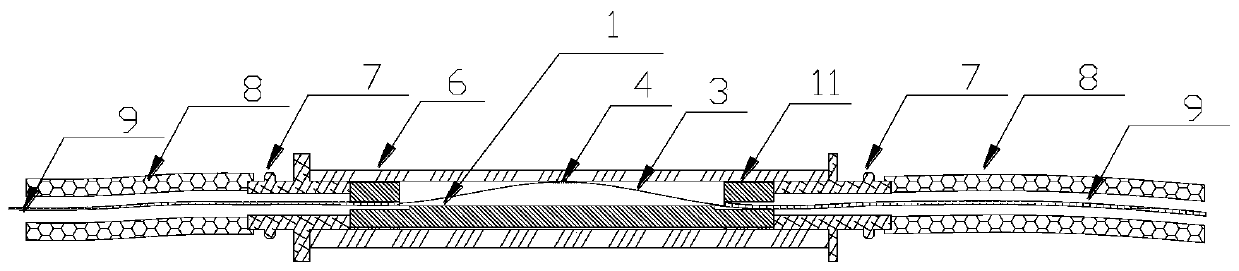

[0030] The calibration-free serial fiber grating temperature sensor preparation method provided by the present invention comprises the following steps:

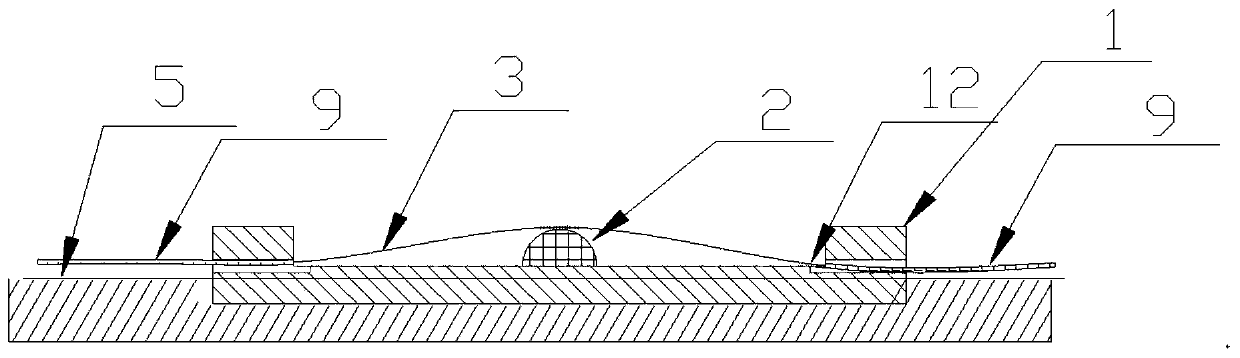

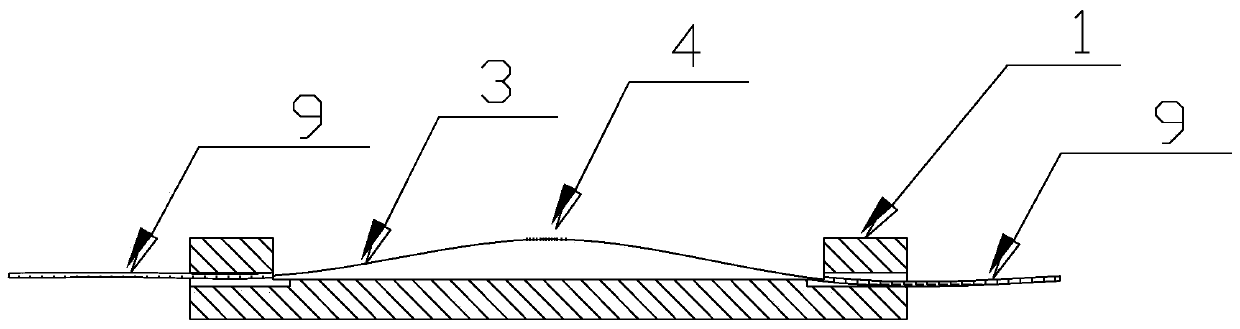

[0031] (1) Embedding the packaged core component in the groove of the horizontal substrate, so that the through holes at both ends of the packaged core component expose the surface of the substrate, such as figure 1 shown;

[0032] The horizontal substrate has at least one groove, preferably a plurality of grooves for mass production, and the plurality of grooves are preferably arranged side by side, so that the fixed package core components are used to set the preset height-setting standard components. position on a straight line. Preferably, the groove is a cylinder, and its cross section is arc-shaped matching the arc of the package core component. The radius of the groove is between 1-3mm, the depth is between 0.9-2.9mm, and the length is between 20- Between 60mm.

[0033] The two ends of the package core are cylinders...

Embodiment 2

[0072] Calibrate and detect the tandem fiber grating temperature sensor prepared in Example 1:

[0073] Sensor temperature coefficient calibration:

[0074] After the fiber grating temperature sensor is packaged, the relaxation state of each grating position is different, resulting in a different temperature coefficient. Here, because of the use of fixed-height standard parts and auxiliary packaging substrates for packaging, good consistency control has been obtained. In the batch of products, only one of the sensors needs to be calibrated to be used for parameter setting of other sensors.

[0075] Step 1: Select the calibration step size according to the required calibration temperature range and desired calibration accuracy, that is, within the calibration temperature range, record a wavelength at a certain temperature interval, and you can choose 10°C, 20°C, 30°C, 40°C as the Calibration step, the shorter the calibration step, the higher the calibration accuracy.

[0076]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com