Method for evaluating adhesion of anti-rut agent to stone material

An anti-rutting agent and evaluation method technology, which is applied in the field of evaluation of anti-rutting agent and stone adhesion, can solve the problems of inaccurate container quality, calculation error, etc., and achieve the effect of simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

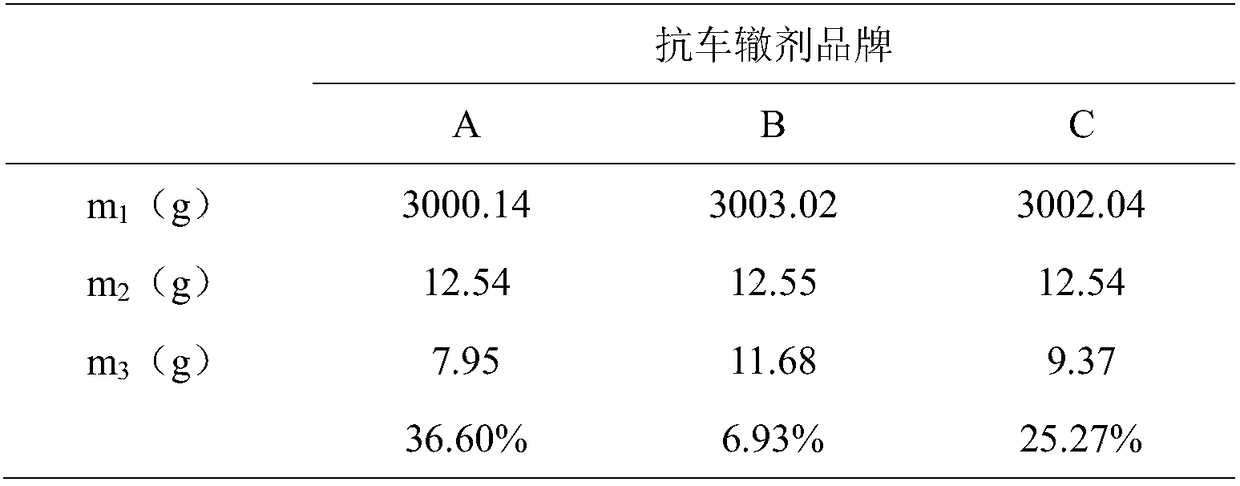

Embodiment 1

[0010] The engineering overview of this embodiment is: the surface layer limestone AC-20 anti-rutting agent asphalt mixture material design in the asphalt pavement of an expressway, and the addition amount is 0.4% of the asphalt mixture mass. There are three brands of anti-rutting agents A, B and C.

[0011] The method of adhesion between anti-rutting agent and stone is used for evaluation.

[0012] 1) Sieve, wash and dry AC-20 limestone aggregates to obtain a number of clean and dry stone samples with a size of 2.36-9.5 mm;

[0013] 2) Weigh an appropriate amount of stone samples, denoted as m 1 , put it in an oven at 180±2°C and heat it for more than 5 hours;

[0014] 3) According to the actual amount added in the project, take some dry samples of three brands of anti-rutting agents A, B, and C in proportion, and record it as m 2 ;

[0015] 4) After preheating the mixing device at 180±2°C for 30 minutes, add the stone sample and anti-rutting agent at the same time, and s...

Embodiment 2

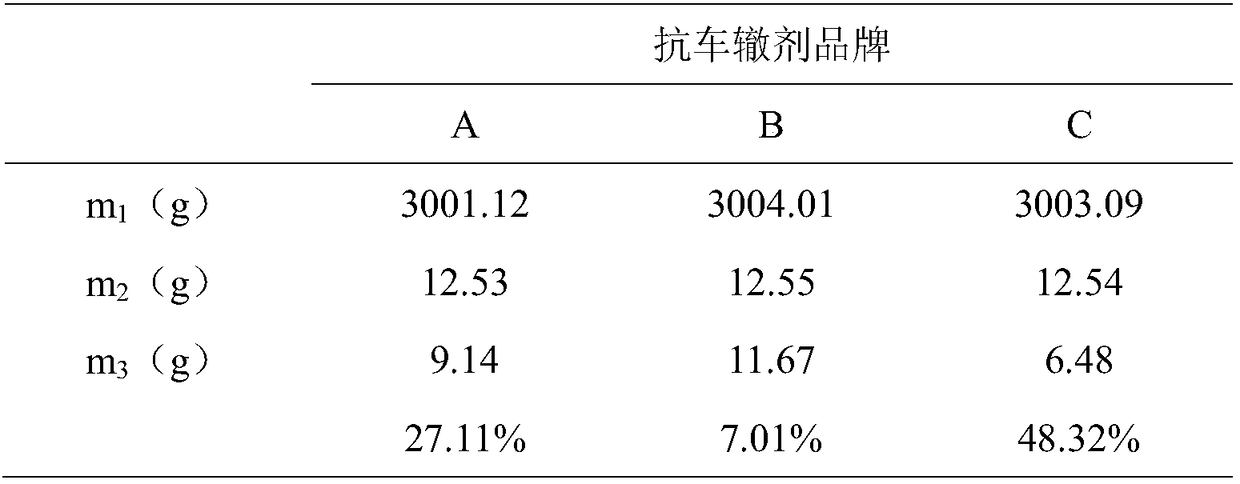

[0022] The engineering overview of this embodiment is: the design of the basalt AC-13 anti-rutting agent asphalt mixture material on the upper layer of the asphalt pavement of a highway, and the addition amount is 0.4% of the asphalt mixture quality. There are three brands of anti-rutting agents A, B and C.

[0023] The method of adhesion between anti-rutting agent and stone is used for evaluation.

[0024] 1) Sieve, wash and dry AC-13 basalt aggregates to obtain a number of clean and dry stone samples with a size of 2.36-9.5mm;

[0025] 2) Weigh an appropriate amount of stone samples, denoted as m 1 , put it in an oven at 180±2°C and heat it for more than 5 hours;

[0026] 3) According to the actual amount added in the project, take some dry samples of three brands of anti-rutting agents A, B, and C in proportion, and record it as m 2 ;

[0027] 4) After preheating the mixing device at 180±2°C for 30 minutes, add the stone sample and anti-rutting agent at the same time, a...

Embodiment 3

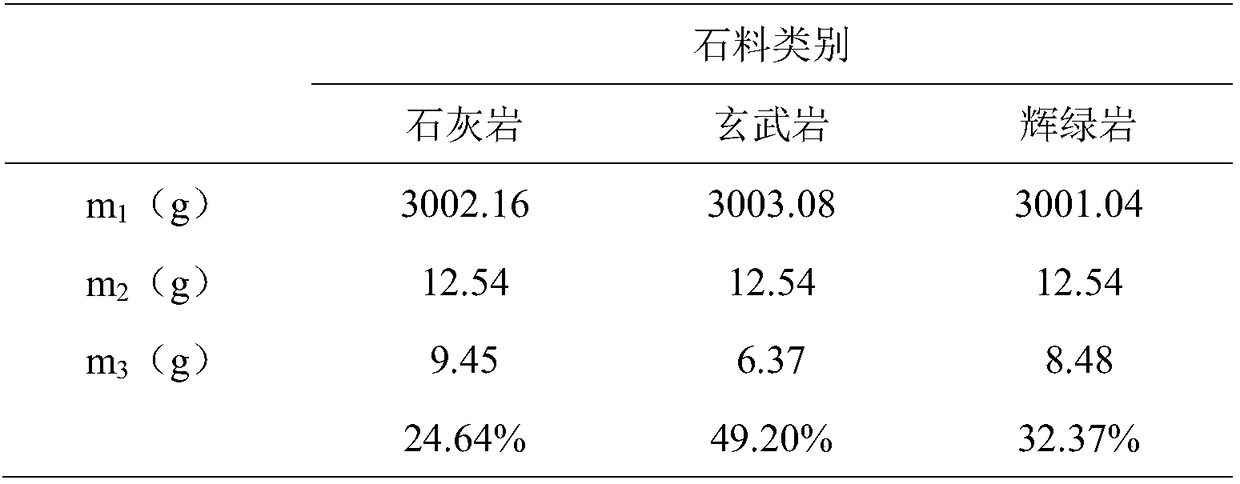

[0034] The engineering overview of this embodiment is: the upper layer of the asphalt pavement of a certain grade of highway is designed with an anti-rutting agent asphalt mixture material, and the addition amount is 0.4% of the asphalt mixture mass. There are three types of stones: limestone, basalt and diabase.

[0035] The method of adhesion between anti-rutting agent and stone is used for evaluation.

[0036] 1) Sieve, wash, and dry limestone, limestone, and diabase aggregates to obtain a number of clean and dry stone samples with a size of 2.36 to 9.5 mm;

[0037] 2) Weigh an appropriate amount of stone samples respectively, denoted as m 1 , put it in an oven at 180±2°C and heat it for more than 5 hours;

[0038] 3) According to the actual amount added in the project, weigh a number of dry anti-rutting agent samples in proportion, and record it as m 2 ;

[0039] 4) After preheating the mixing device at 180±2°C for 30 minutes, add the stone sample and anti-rutting agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com