Feeding and detecting mechanism of automatic pipe chamfering machine

A technology of detection mechanism and feeding mechanism, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of affecting the work of the chamfering machine, no processing and detection process, etc., and achieve the effect of efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

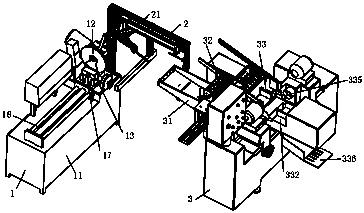

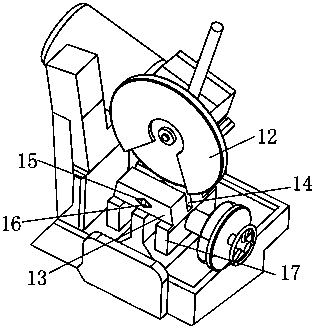

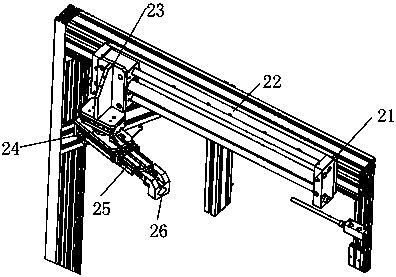

[0015] Combine below Figure 1 to Figure 6 Specific description embodiment:

[0016] The automatic pipe cutting and chamfering processing equipment for auto parts pipes is characterized in that it includes a pipe cutting machine 1, a transmission device 2 and a chamfering machine 3, and the pipe cutting machine 1 includes a base 11 on which A cutting wheel device 12 and a positioning block 13 are provided, a slot 14 is formed between the two positioning blocks 13, and a feeding positioning hole 15 is provided on the positioning block 13, and the feeding positioning hole 15 is diamond-shaped, 4 pipes 16 are arranged in the feeding positioning hole, and the 4 pipes are distributed in the feeding positioning hole in a petal shape. The straight line formed by the feeding positioning holes on the two positioning blocks is perpendicular to the cutting groove. The bottom of the positioning block A slider 17 is provided, and the slider 17 is connected with a pull rod 18, and the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com