Adapter used for numerical control machining of ball bolt countersinks

A technology for adapters and sink holes, which is applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of high price and difficult maintenance, and achieve the effects of high processing accuracy, low cost, convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

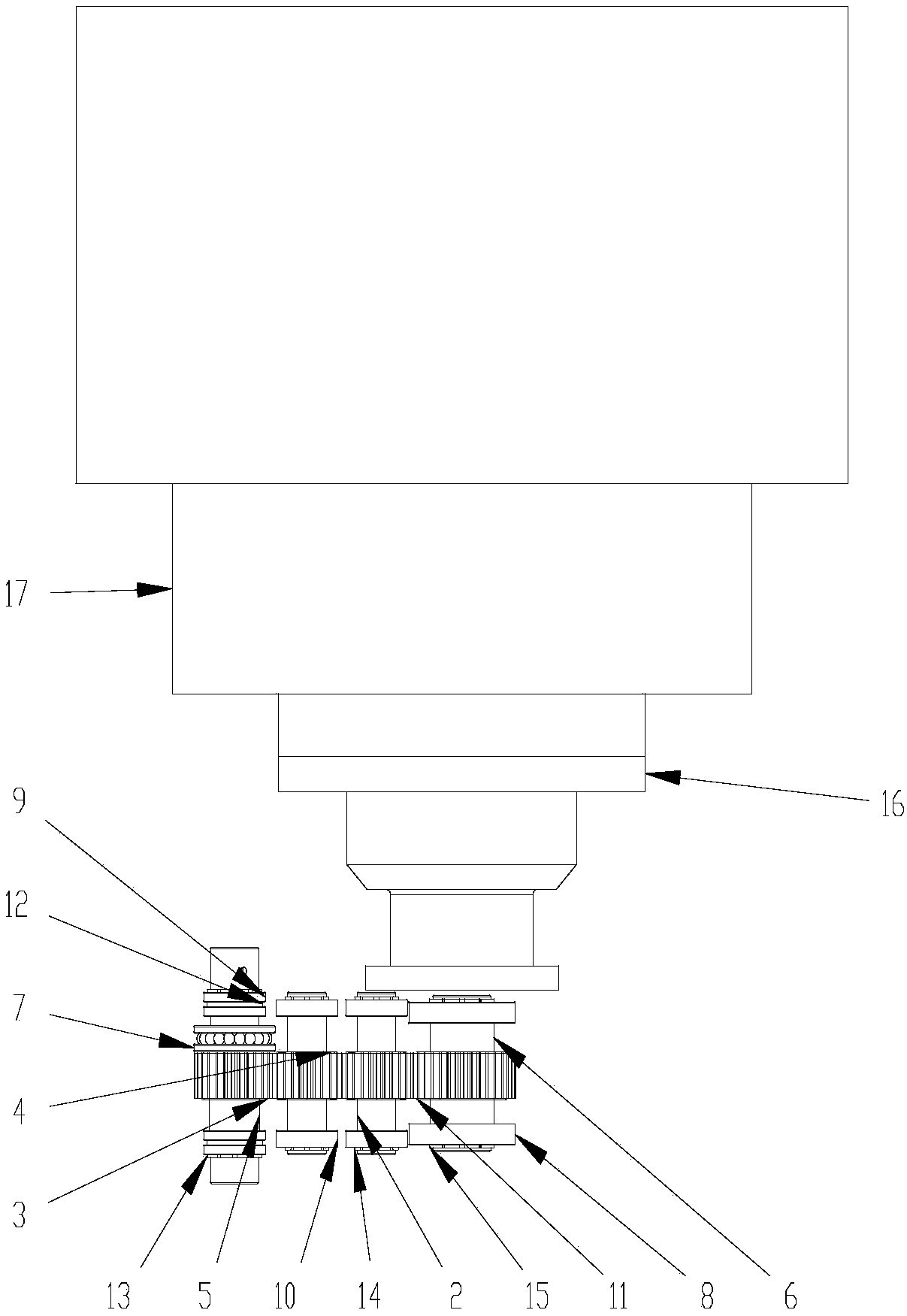

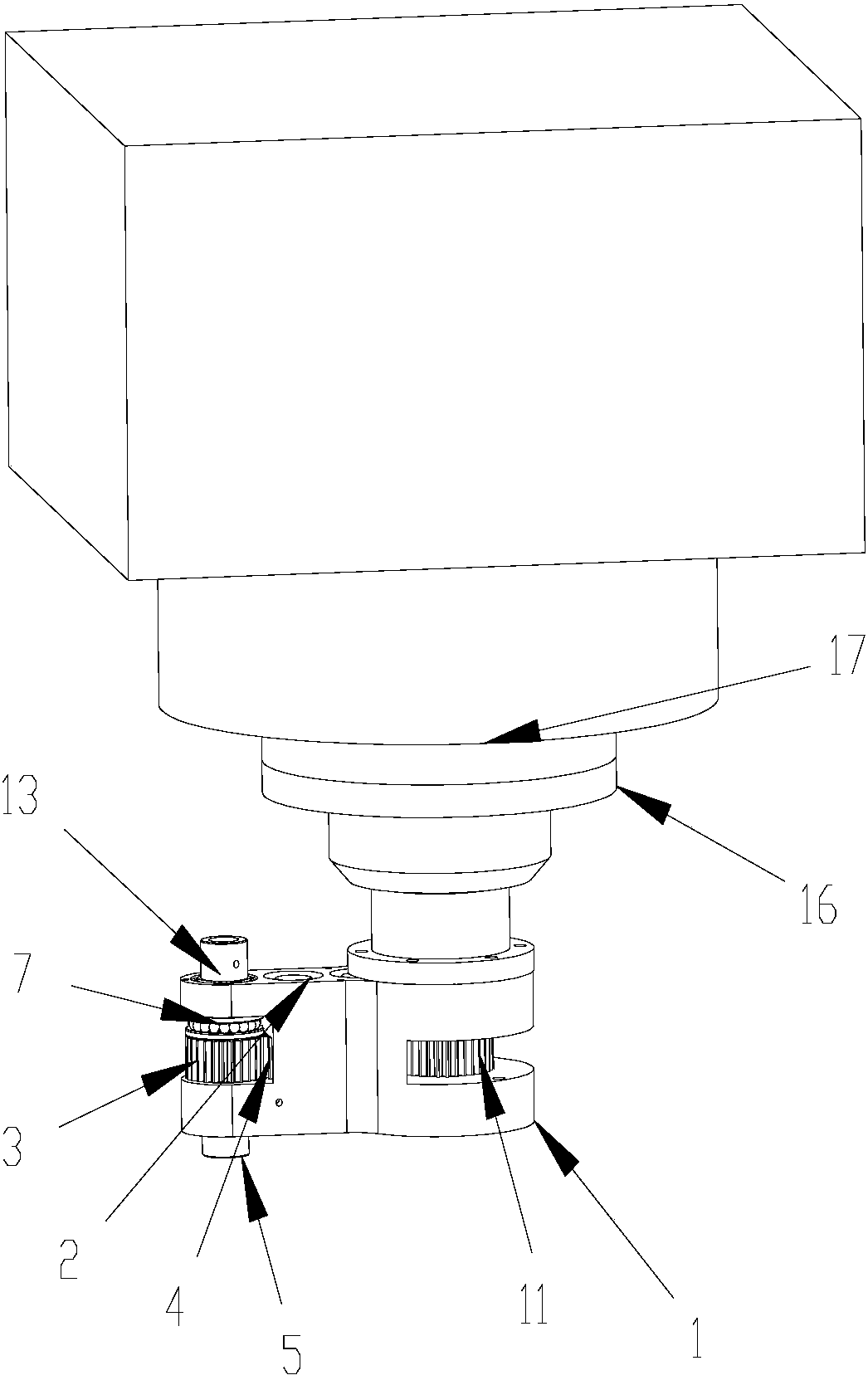

[0042] A kind of numerical control machining ball bolt countersunk hole adapter, its structure is as follows figure 1 As shown, it includes a gearbox connecting sleeve 16 connected to the main shaft 17 of the machining center, the first gear shaft 6 coaxially arranged at the lower end of the main shaft 17 of the machining center, the intermediate gear shaft 2 and the third gear arranged in parallel with the first gear shaft 6 in sequence Axis 5.

[0043] The first gear 11 is sheathed on the first gear shaft 6 , the number of teeth Z is 35, and the modulus M is 1.5. There are two intermediate wheel shafts 2, and each intermediate wheel shaft 2 is provided with a second gear 4, the number of teeth Z is 24, and the modulus M is 1.5. The third gear shaft 5 is sheathed with the third gear 3, the number of teeth Z is 26, and the modulus M is 1.5. The first gear 11, the two second gears 4 and the third gear 3 are sequentially meshed and connected.

[0044] The upper and lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com