Double swash device and method for ship liquid tank

A technology for liquid tanks and ships, which is applied to ship accessories, load handling devices, transportation and packaging, etc. It can solve the problems of high construction cost, low level of liquid tanks, and complicated structure of the swaying device, so as to reduce damage and drop the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

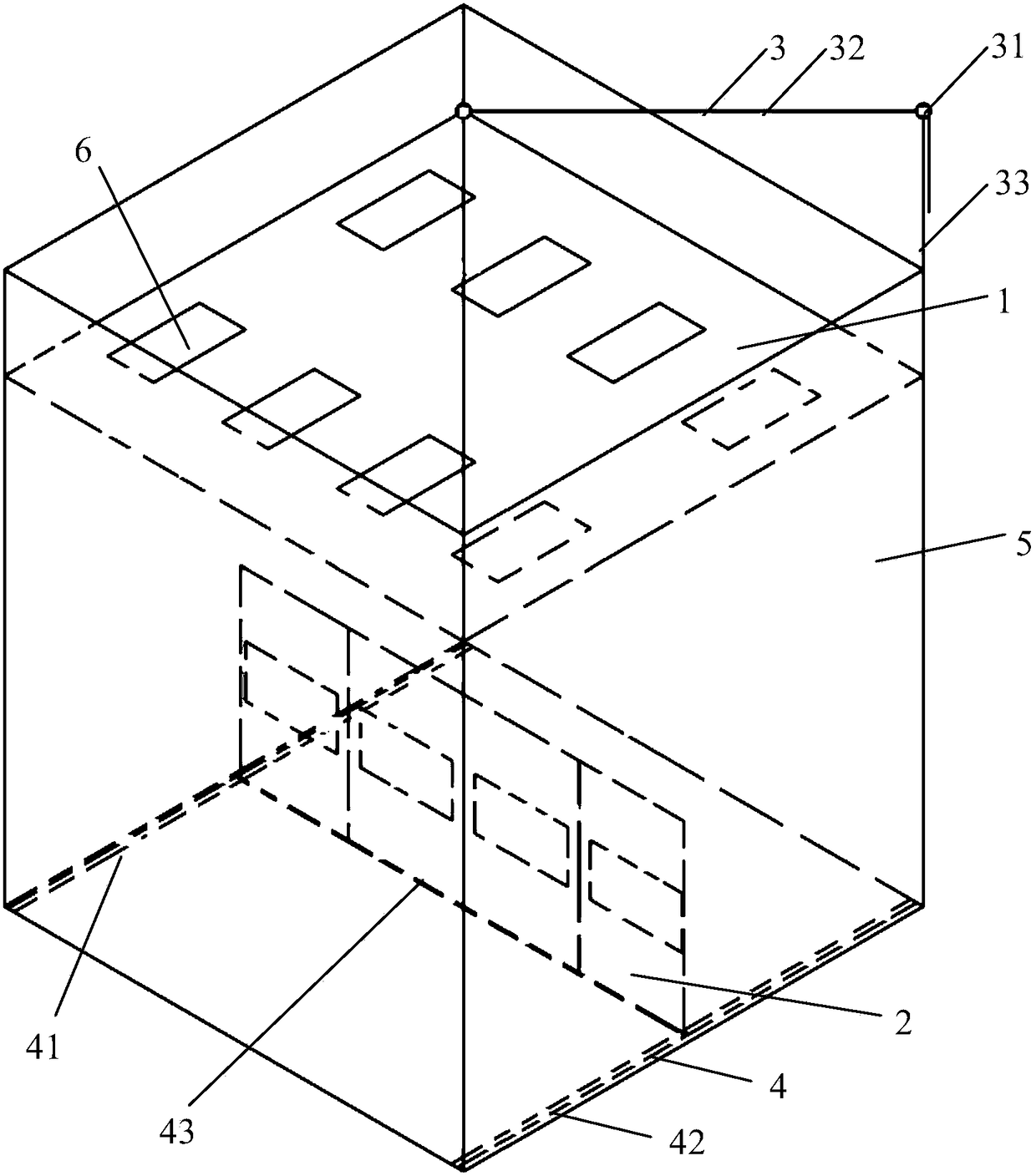

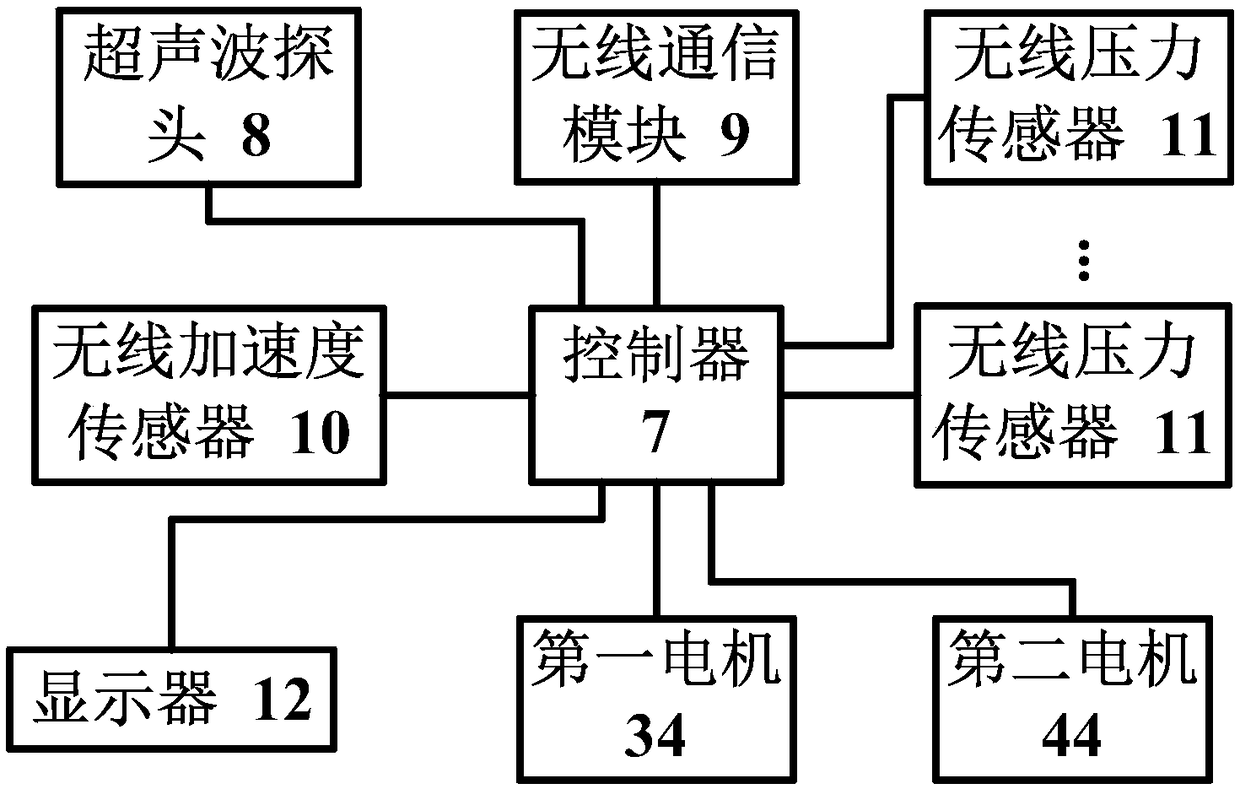

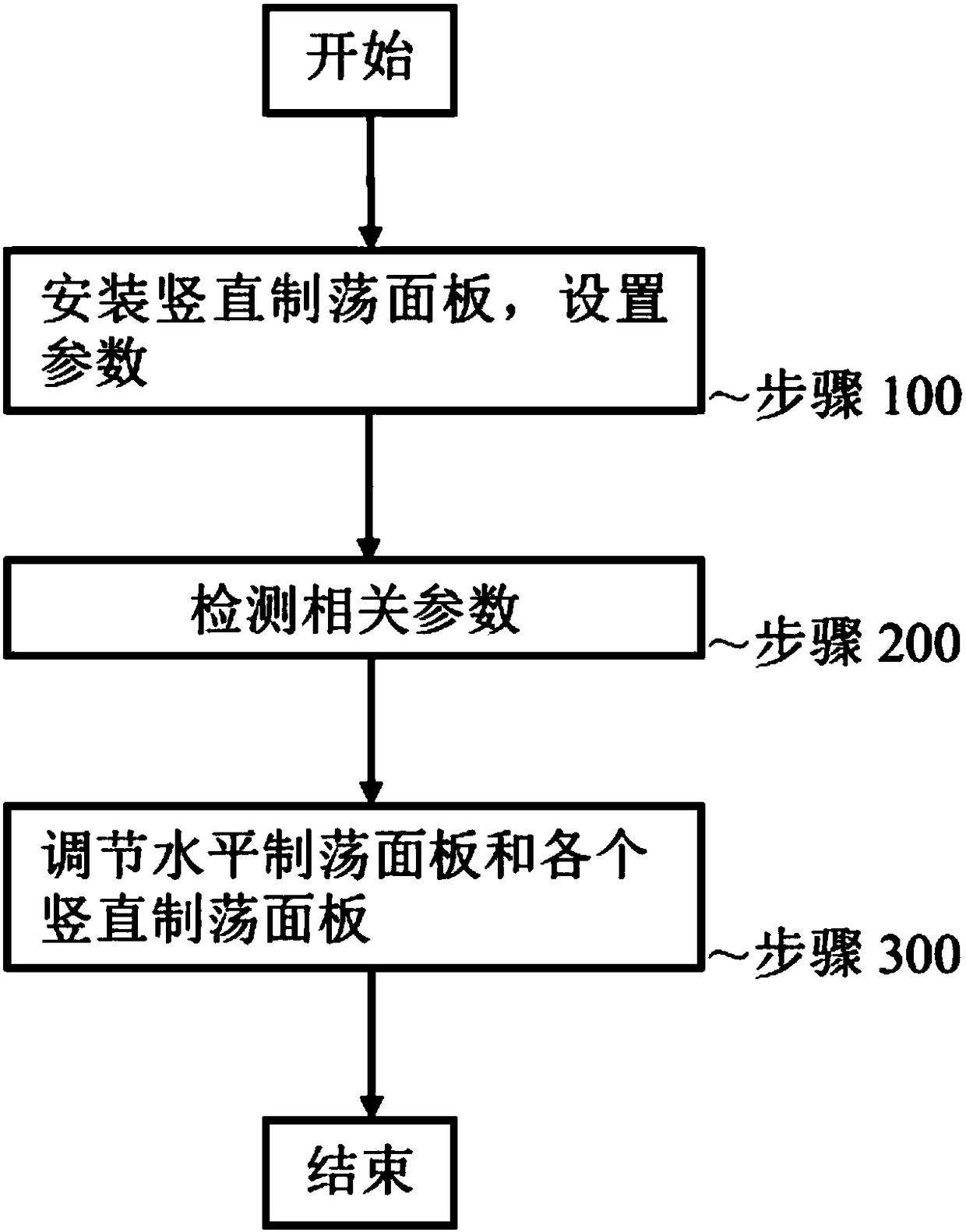

[0029] Such as figure 1 and figure 2 The illustrated embodiment is a dual wash device for tanks in ships, including a horizontal wash panel 1, two vertical wash panels 2, a horizontal wash panel connecting device 3 and a vertical wash panel connecting device 4; The connecting device of the horizontal sway panel comprises a fixed pulley 31, a traction wire rope 32, a fixed arm 33 and a first motor 34, one end of the fixed arm is connected with the tank 5 of the ship, and the other end of the fixed arm is connected with the fixed pulley, so One end of the steel wire traction rope passes through the fixed pulley and is connected to the horizontal swing panel, and the other end of the steel wire traction rope is connected to the first motor; the vertical swing panel connection device includes a first transverse track 41 and a second transverse track 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com