Method and system for controlling pulse purification of sewage

A control system and control method technology, applied in control/manipulation systems, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as uneven sewage discharge, uneven sewage discharge, increased energy consumption of sewage treatment facilities, etc. To achieve the effect of improving self-adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

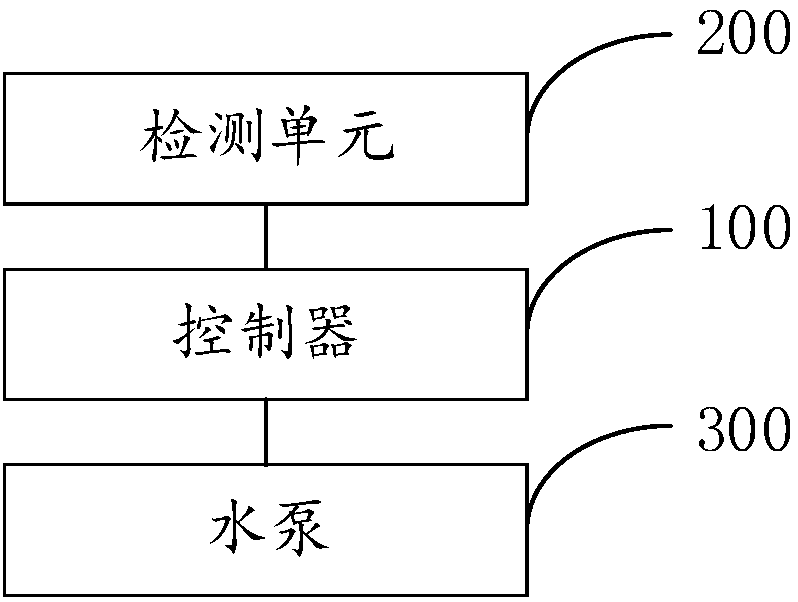

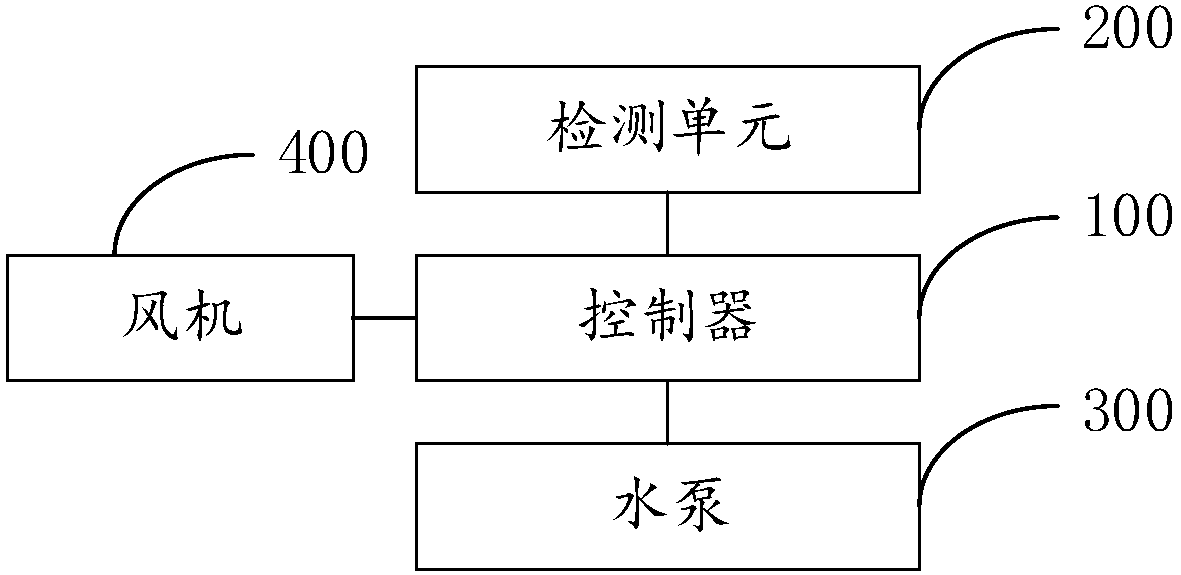

[0057] see figure 1 , is a schematic diagram of the functional modules of the sewage pulsation purification control system provided by a preferred embodiment of the present invention. The sewage pulsation purification control system is applied to sewage treatment facilities, especially small sewage treatment facilities with extremely uneven sewage discharge. The sewage pulsation purification control system includes a controller 100 , a detection unit 200 and a water pump 300 , and the controller 100 is electrically connected to the detection unit 200 and the water pump 300 for signal interaction.

[0058] Wherein, the detection unit 200 is used to detect the current environmental parameters of the regulating pool. The sewage treatment facility is provided with a regulating pond, and the detection unit 200 is arranged in the regulating pond to detect the current environmental parameters of the regulating pond. In the embodiment of the present invention, the current environment...

no. 2 example

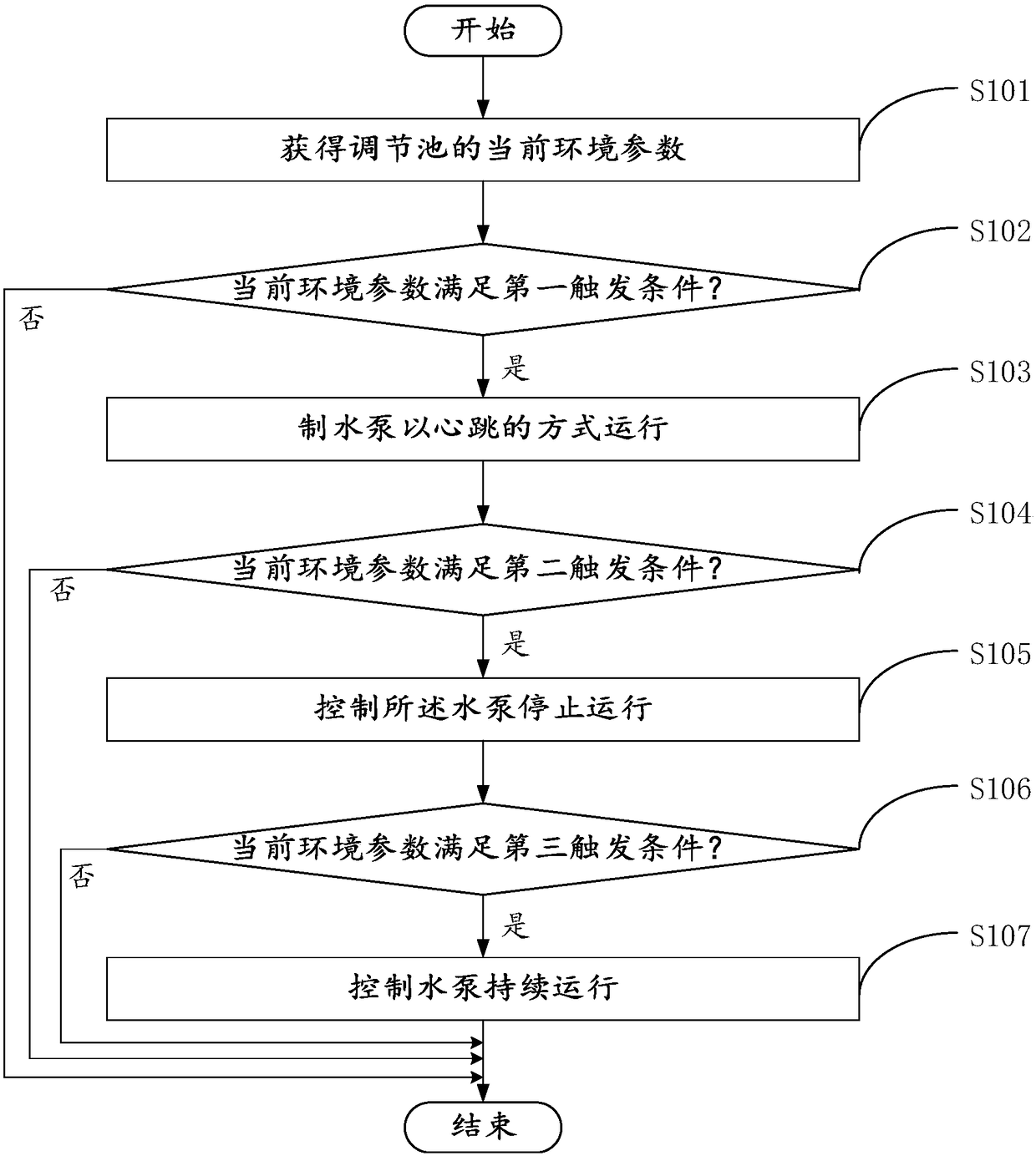

[0078] refer to image 3 , the flow chart of the sewage pulsation purification control method provided in this embodiment, the following will image 3 The process shown is described in detail.

[0079] Step S101, obtaining the current environmental parameters of the regulating pool.

[0080]The sewage pulsation purification control method provided by the embodiment of the present invention is applied to the sewage pulsation purification control system, and the sewage pulsation purification control system includes a controller 100, a detection unit 200 and a water pump 300, and the controller 100 communicates with the detection unit 200 and the water pump 300 respectively. Electrically connected for signal interaction.

[0081] The sewage treatment facility is provided with a regulating tank, and the detection unit 200 is arranged in the regulating pond, and the detecting unit 200 detects the current environmental parameters of the regulating pond and feeds back to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com