Fused azs bricks resistant to corrosion by low iron glass

A technology of low-iron glass and electrofusion, which is applied in the field of refractory materials, can solve problems such as no corresponding solutions have been proposed, and achieve the effect of large phase transition stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

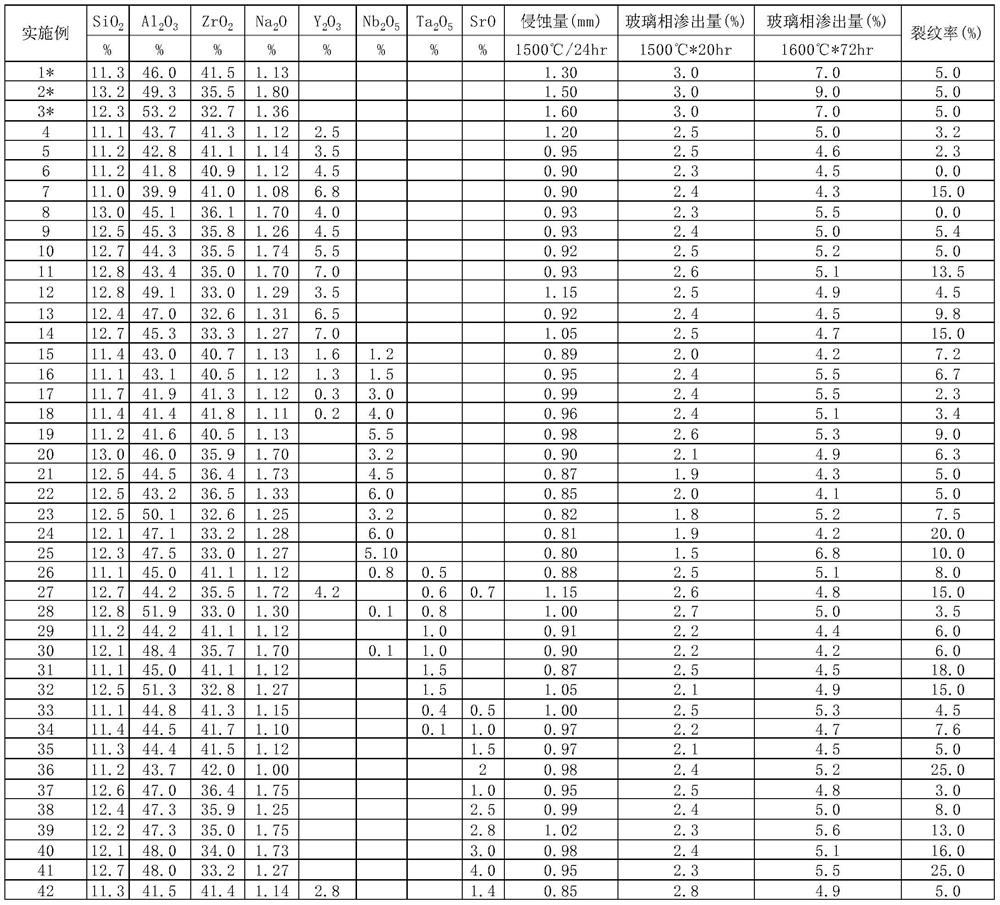

Examples

Embodiment 26

[0043] Examples 26, 28-31 show that Ta 2 o 5 When ≥1.5wt.%, the crack rate rises sharply, and when the content is 1wt.%, all indexes are in the best range.

[0044] Examples 33-42 show that the addition of SrO has a significant effect on enhancing the corrosion resistance and reducing the exudation of the glass phase at 1500°C, but the crack rate increases sharply when the addition amount is above 3wt.%.

[0045] Analysis shows that the product of the present invention is particularly suitable for low-iron glass furnaces, such as common photovoltaic rolling glass furnaces, ultra-clear glass furnaces, etc.; of course, it will have a longer service life when used in ordinary float glass furnaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com