A kind of high-transparency temperable triple-silver low-e glass and preparation method thereof

A high-transparency temperable triple-silver, low-e technology, applied in the direction of coating, etc., can solve the problems of low-E glass transmittance, machinability, poor machinability, low sunlight transmittance, etc. , to achieve excellent smooth surface characteristics, good mechanical processing performance, and improve the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

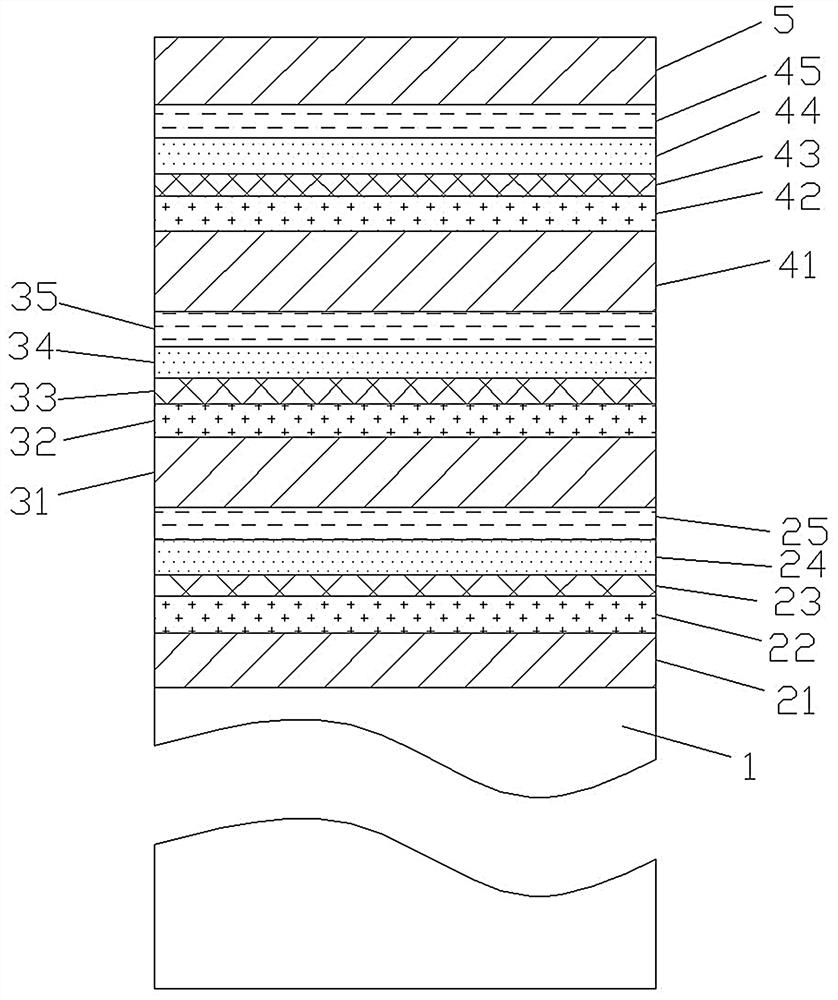

[0057] like figure 1 As shown, the present invention provides a high-transparency temperable triple-silver Low-E glass, including a glass substrate 1, and the top surface of the glass substrate 1 is stacked with sixteen film layers sequentially from bottom to top, wherein the first film layer 21 is Si 3 N 4 layer, the second film layer 22 is TiO 2 layer, the third film layer 23 is a NiCr layer, the fourth film layer 24 is an Ag layer, the fifth film layer 25 is an AZO layer, and the sixth film layer 31 is a Si 3 N 4 layer, the seventh film layer 32 is TiO 2 layer, the eighth film layer 33 is a NiCr layer, the ninth film layer 34 is an Ag layer, the tenth film layer 35 is an AZO layer, and the eleventh film layer 41 is a Si 3 N 4 layer, the twelfth film layer 42 is TiO 2 layer, the thirteenth film layer 43 is a NiCr layer, the fourteenth film layer 44 is an Ag layer, the fifteenth film layer 45 is an AZO layer, and the sixteenth film layer 5 is a Si 3 N 4 Floor.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com