Homo-tooth electrical tracking mechanism for single-tooth quenching machine

A technology of quenching machine tool and tracking mechanism, which is applied in the direction of quenching device, improvement of process efficiency, furnace type, etc., can solve the problems of tracking and positioning cannot be guaranteed, different tooth positioning, etc., and achieve constant relative position relationship, stable quenching layer depth and hardness , the effect of increased versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

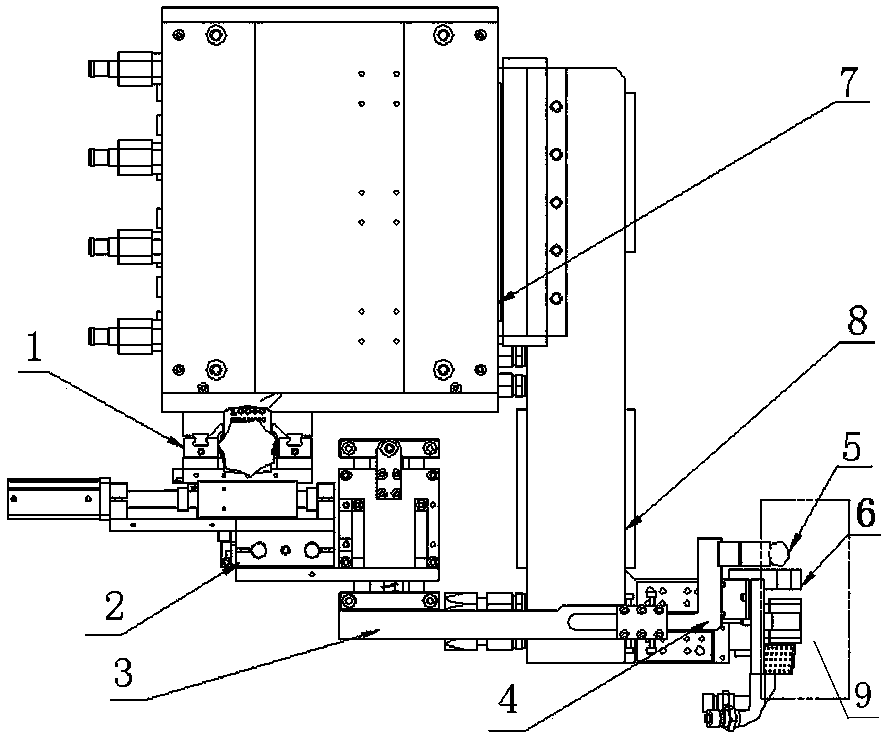

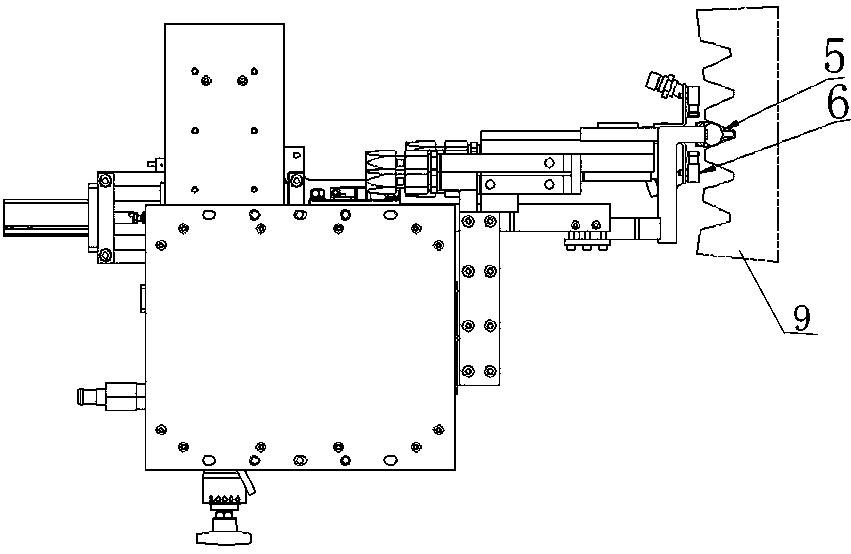

[0030] Such as figure 1 , 2 , 3, 4, 5, and 6.

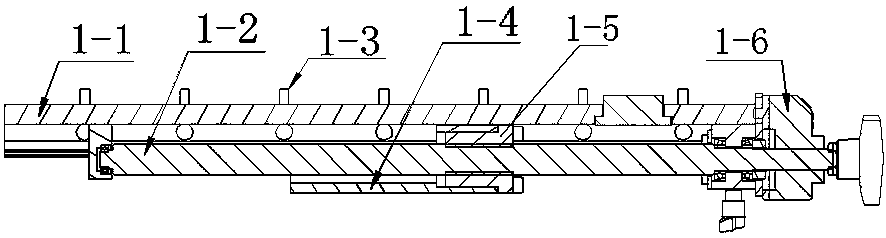

[0031] A same-tooth electrical tracking mechanism for a single-tooth quenching machine tool, including a quenching load 7, the quenching load 7 is fixedly connected to a single-tooth quenching inductor 6 through a transition row 8, and a one-dimensional adjustment unit 1 is provided under the quenching load 7, wherein The fixed plate 1-1 in the one-dimensional adjustment unit 1 is fixed under the quenching load 7 through the mounting bolts 1-3, and the lower 1-1 of the fixed plate is provided with a ball screw or a trapezoidal screw 1-2, a ball screw or a trapezoidal screw 1-2 is screwed with a threaded female seat 1-5, and the threaded female seat 1-5 is fixed on the mounting plate 1-4 of the one-dimensional adjustment unit, and the end of the ball screw or trapezoidal screw 1-2 is provided with a locking The device 1-6 is correspondingly connected with the fixed plate 1-1;

[0032] A three-dimensional floating unit is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com