High-strength Co-CaO cobalt alloy and preparation method thereof

A cobalt alloy, high-strength technology, applied in the field of high-strength Co-CaO cobalt alloy and its preparation, can solve the problems of high modification cost, insufficient effect, insufficient performance of cobalt alloy material, etc., so as to improve mechanical properties and reduce material Cost, the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

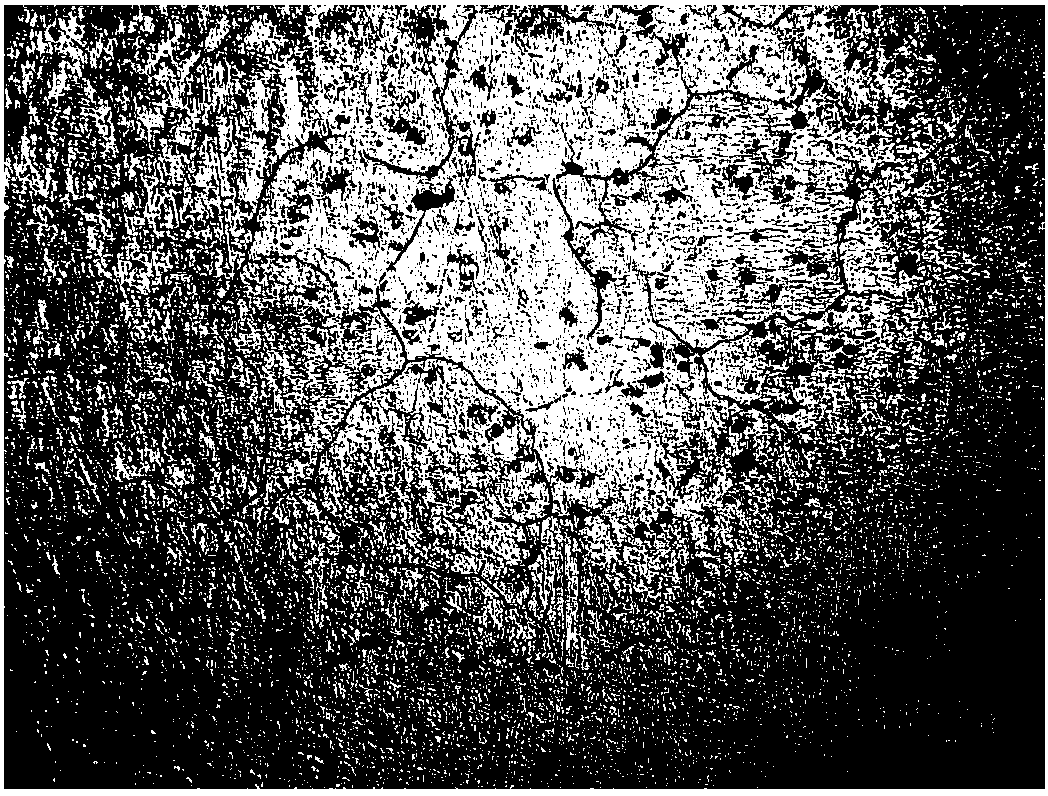

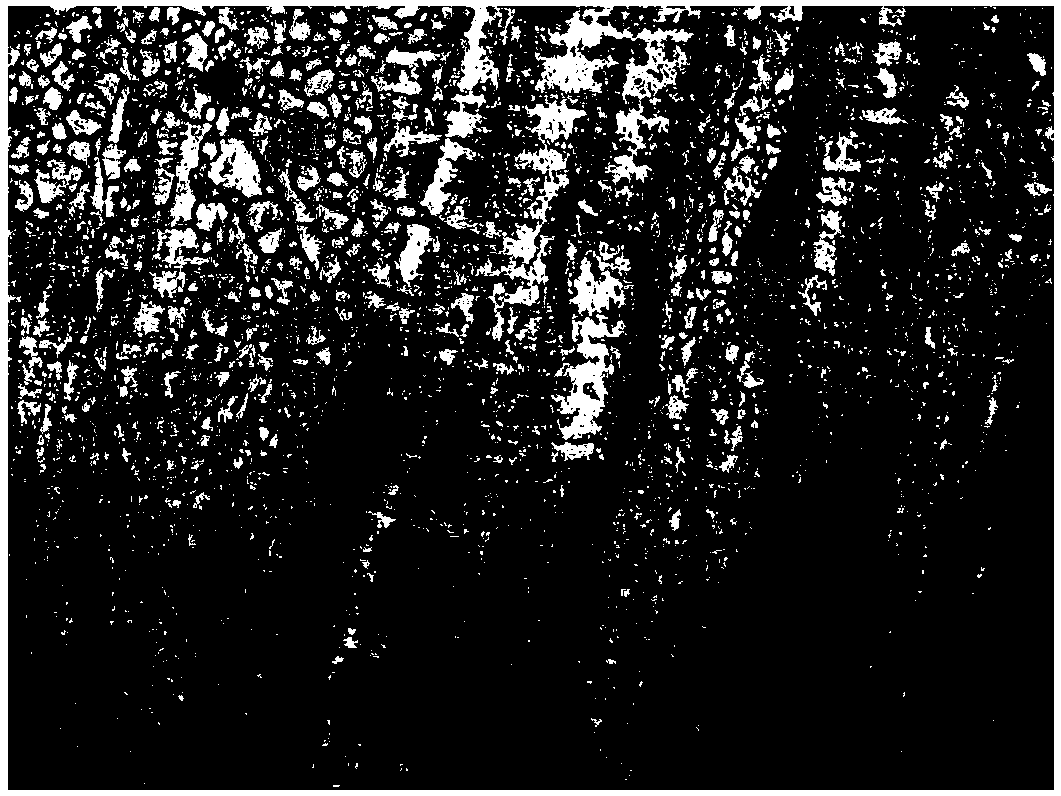

Image

Examples

Embodiment 1

[0034] The high-strength Co-CaO cobalt alloy of the present embodiment comprises the following components: Co commercial cobalt alloy, 0wt% CaO (wt% refers to the percentage that the weight of each component accounts for the total weight of the target alloy, and this total weight is Co commercial cobalt alloy total weight).

[0035] The preparation method is as follows:

[0036] Melting process: the whole melting process is in SF 6 and CO 2 Under the condition of mixed gas protection. Weigh the Co commercial cobalt alloy according to the formula quantity, and then bake the weighed raw material at 180° C. for more than 3 hours. Put the dried Co commercial cobalt alloy into the SF 6 and CO 2 Heat and melt in a crucible resistance furnace protected by a mixed gas to obtain a molten Co cobalt liquid. When the temperature of the cobalt liquid rises to 720°C, keep the temperature constant, sprinkle the pre-weighed refining agent evenly on the cobalt liquid, and stir for 10 minu...

Embodiment 2

[0041] The high-strength cobalt alloy of the present embodiment comprises the following components in mass percentage: Co commercial cobalt alloy, 1wt% CaO (wt% refers to the percentage of the weight of each component accounting for the total weight of the target alloy, and the total weight is Co total weight of commercial cobalt alloys).

[0042] The preparation method is as follows:

[0043] Melting process: the whole melting process is in SF 6 and CO 2 Under the condition of mixed gas protection. Weigh the Co commercial cobalt alloy according to the formula quantity, and then bake the weighed raw material at 180° C. for more than 3 hours. Put the dried Co commercial cobalt alloy into the SF 6 and CO 2Heat and melt in a crucible resistance furnace protected by a mixed gas to obtain molten Co cobalt liquid. When the temperature of the cobalt liquid rises to 740°C, keep the temperature constant. Use a stainless steel bell jar to press the CaO powder wrapped in aluminum fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com