Travel control apparatus of brick laying machine

A technology for the stroke and control device of a brick laying machine, which is applied in the direction of roads, road repairs, roads, etc., can solve problems such as low work efficiency, increased construction budget, and waste of labor, and achieves the effects of convenient operation, simple structure, and accurate and consistent strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

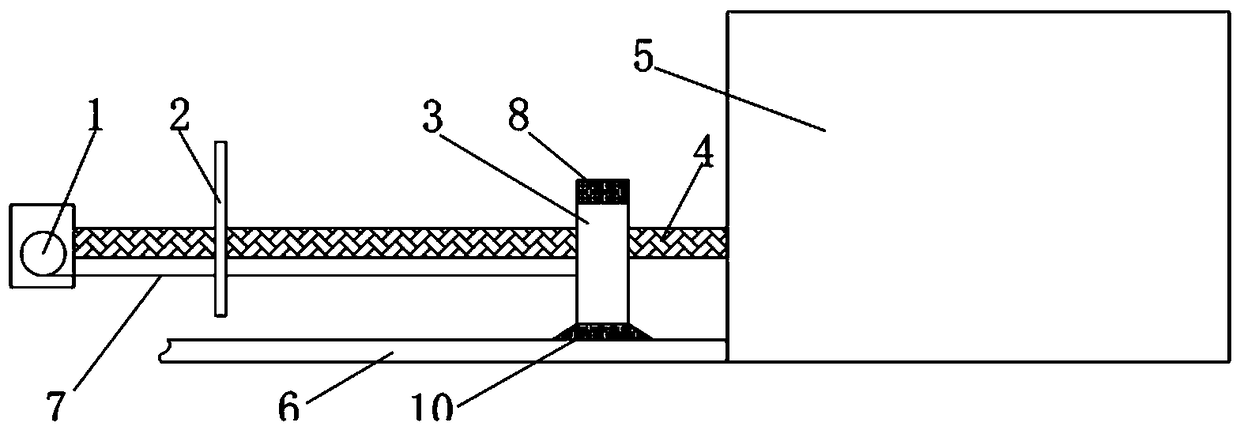

[0024] Such as figure 1 and figure 2 As shown, the stroke control device of the brick laying machine includes a coiler 1, a baffle plate 2, a parking device 3 and a guide rail 4. The guide rail 4 is located above the track 6 of the brick laying machine 5 and is parallel to each other. The guide rail 4 is installed on the brick laying machine 5 front end, the guide rail 4 extends along the front end of the brick laying machine 5 to the direction of movement, and the parking device 3, the baffle plate 2 and the coiler 1 are sequentially distributed outward, and the parking device 3 is provided with a limit switch, and the brick laying machine 5 The position corresponding to the parking device 3 on the baffle 2 is also equipped with a matching limit switch. The retractor 1 is composed of a retracting device with a built-in elastic sheet and a retractable pull rope 7, and the pull rope 7 passes through the baffle 2 Connect with parker.

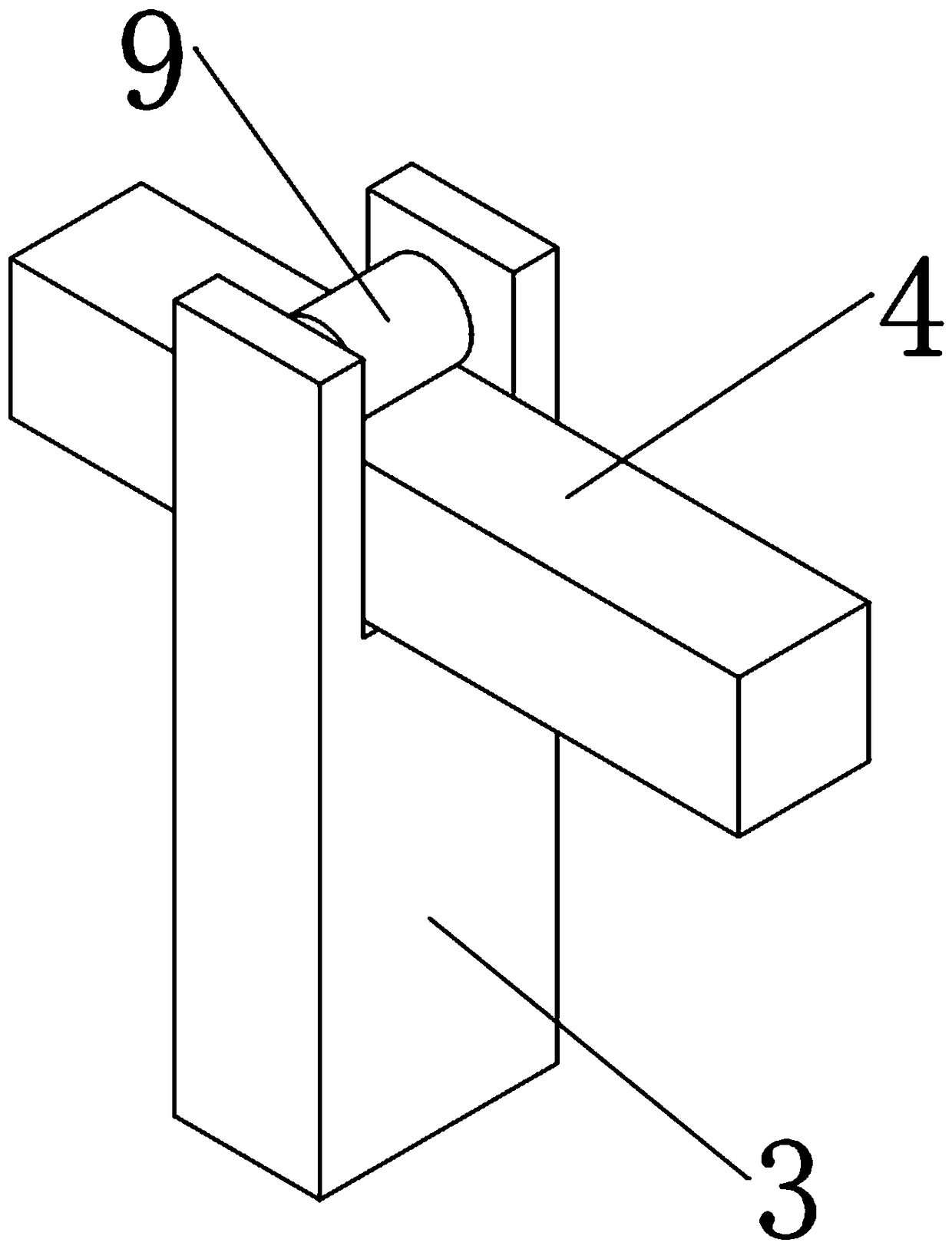

[0025] The upper end of the parking devi...

Embodiment 2

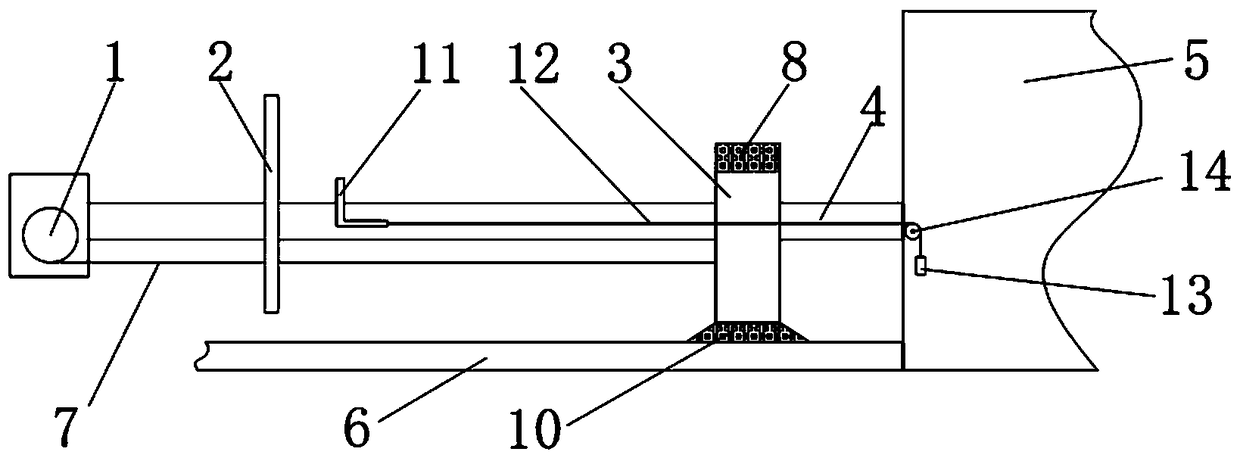

[0033] Such as image 3 and Figure 4As shown, the specific implementation is the same as in Example 1, the difference is that: an intercepting hook 11 is installed at one end of the baffle plate 2 on the guide rail 4, and the intercepting hook 11 moves back and forth near one end of the baffle plate on the guide rail, and the intercepting hook 11 is L-shaped. The lower end is connected to the guide rope 12 to make piston movement in the guide rail 4, and the upper end extends out of the guide rail 4. The other end of the guide rope is provided with an inertial body 13, and a guide wheel 14 is installed at the end of the guide rail 4, so that the guide rope can be pulled outside the guide rail after passing the guide wheel. The inertial body sags naturally. The inertial body 13 is made up of a central axis 15, a spring 16, and a falling body 17. The central axis 15 is a ⊥-shaped structure. A hole suitable for the size of the central axis is set at the center of the falling bod...

Embodiment 3

[0036] Such as Figure 5 As shown, the specific implementation is the same as in Example 1, and the difference is that the guide rail 4 is installed between the front and rear wheels of the brick laying machine 5, and the guide rail 4 is along the brick laying machine 5 (in the figure, only the frame of the brick laying machine 5 The rear wheel extends to the front wheel. On the guide rail 4, the parking device 3, the baffle 2 and the retractor 1 are distributed sequentially from the rear wheel to the front wheel. The purpose of stopper 3 swinging left and right. The coiler 1 is installed on the parking device 3, and the end of the stay rope passes through the baffle and is fixed on the brick laying machine in front of the baffle, so as to simplify the device and facilitate installation.

[0037] When this device is used in combination with a brick laying machine, guide rails are installed between the front and rear wheels of the brick laying machine and on the track, and lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com