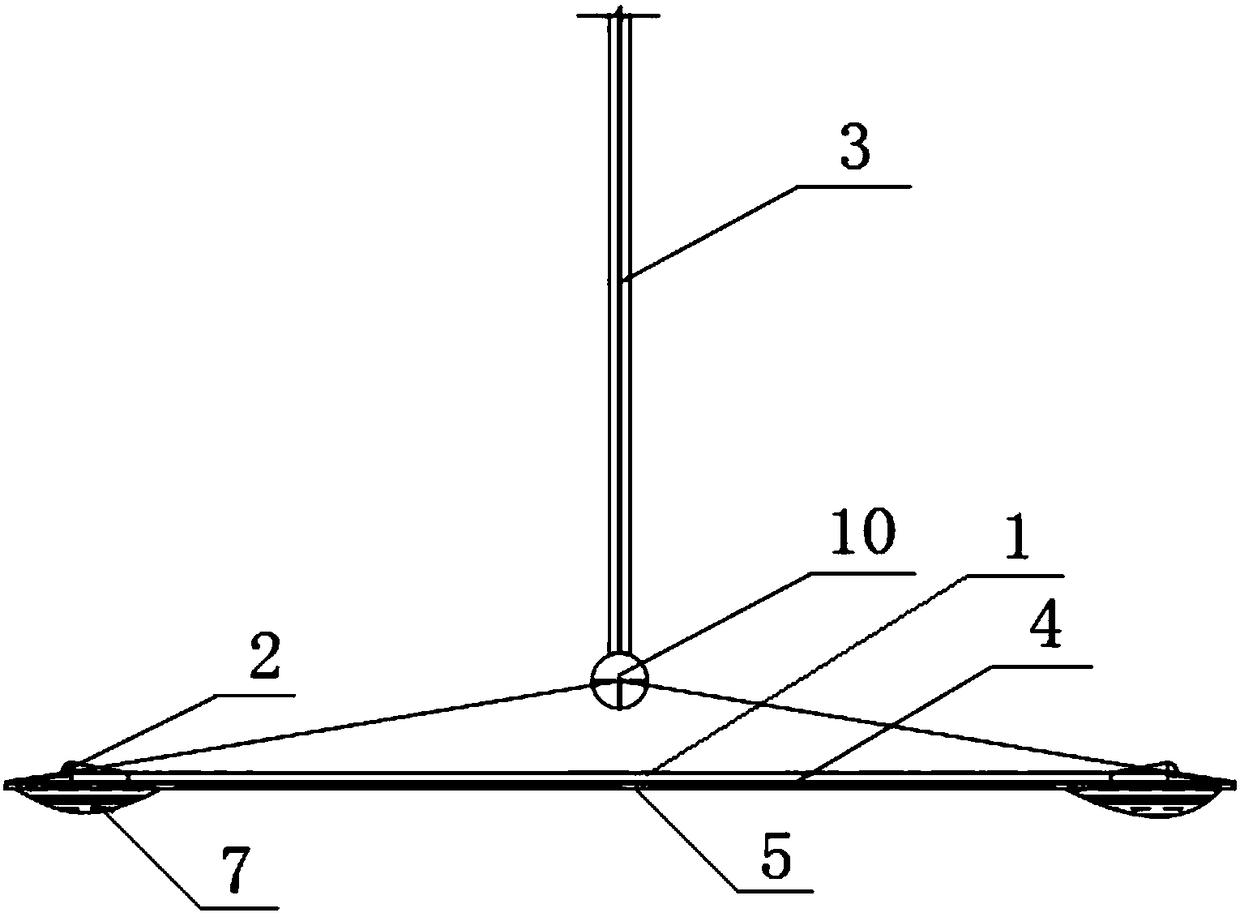

Vacuum prepressing underwater double-adhesive film repairing device and method

A pre-pressing and vacuum technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high construction cost, difficult to guarantee the quality of the film, and prolong the construction period, so as to achieve increased construction cost, simple construction, and extended construction period. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

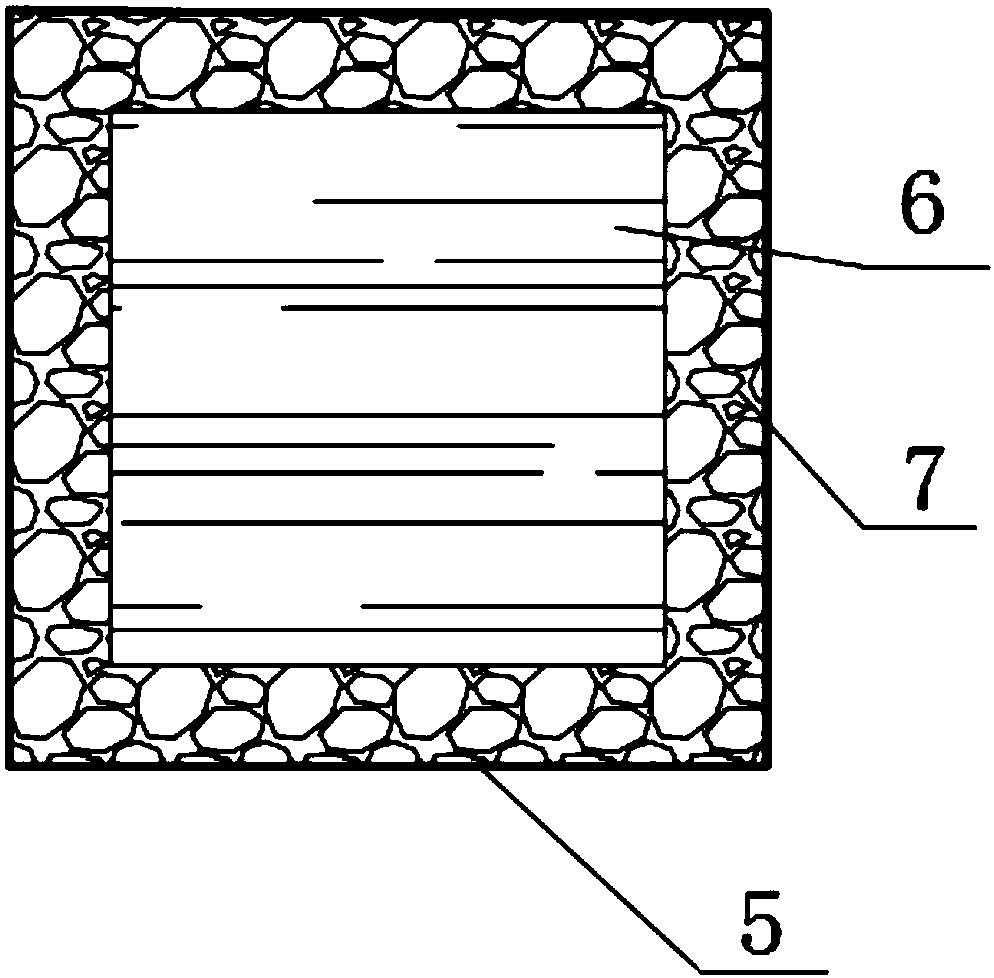

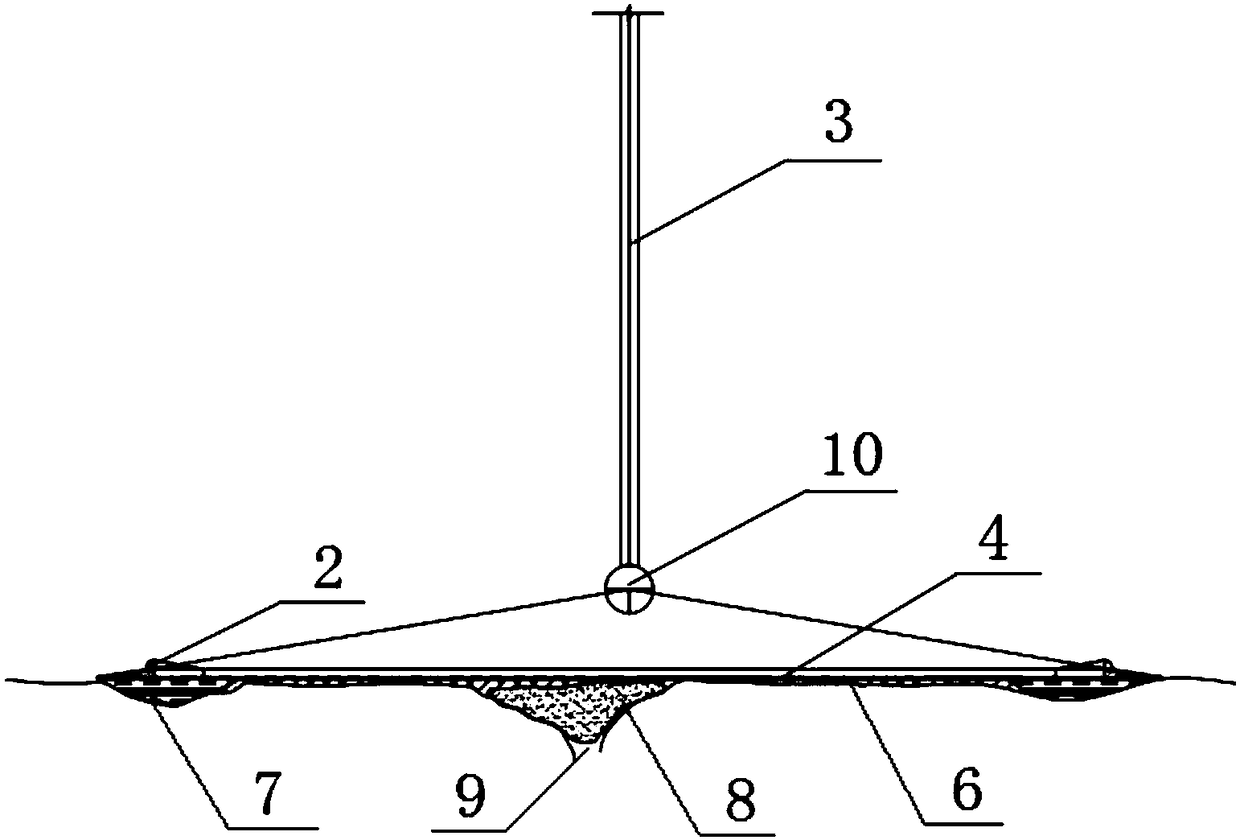

Method used

Image

Examples

Embodiment 1

[0074] 1. For a 2×60MW natural gas distributed energy station project in a high-tech zone, the foundation treatment adopts water-covered vacuum preloading, the water cover height is 1.5 meters, and there is a fill layer of nearly 4 meters under the membrane. Large, causing the relative displacement between the sealing film and the monitoring pipe to be close to 1.5 meters during construction. Since the drainage board is constructed by the way of leading holes, there are many holes under the sealing film. Most of the holes have been treated with sand filling and compaction before laying the sealing film, but there are still some holes that are preloaded under vacuum due to the vacuum. Run, and the sealing film will be broken by suction. Since the hole is close to 1.5 meters below the water cover, it is difficult to repair the sealing film. After repeated research, the underwater double-glue sealing method of this embodiment is adopted for processing. The specific implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com