Wood frame beam-column self-resetting joint based on shape memory alloy bolts

A memory alloy, self-resetting technology, applied in building components, earthquake resistance, building types, etc., can solve problems such as affecting the aesthetics of the structure, low node stiffness, demolition, etc., and achieve the effect of improving pinching defects, structural self-resetting, and structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

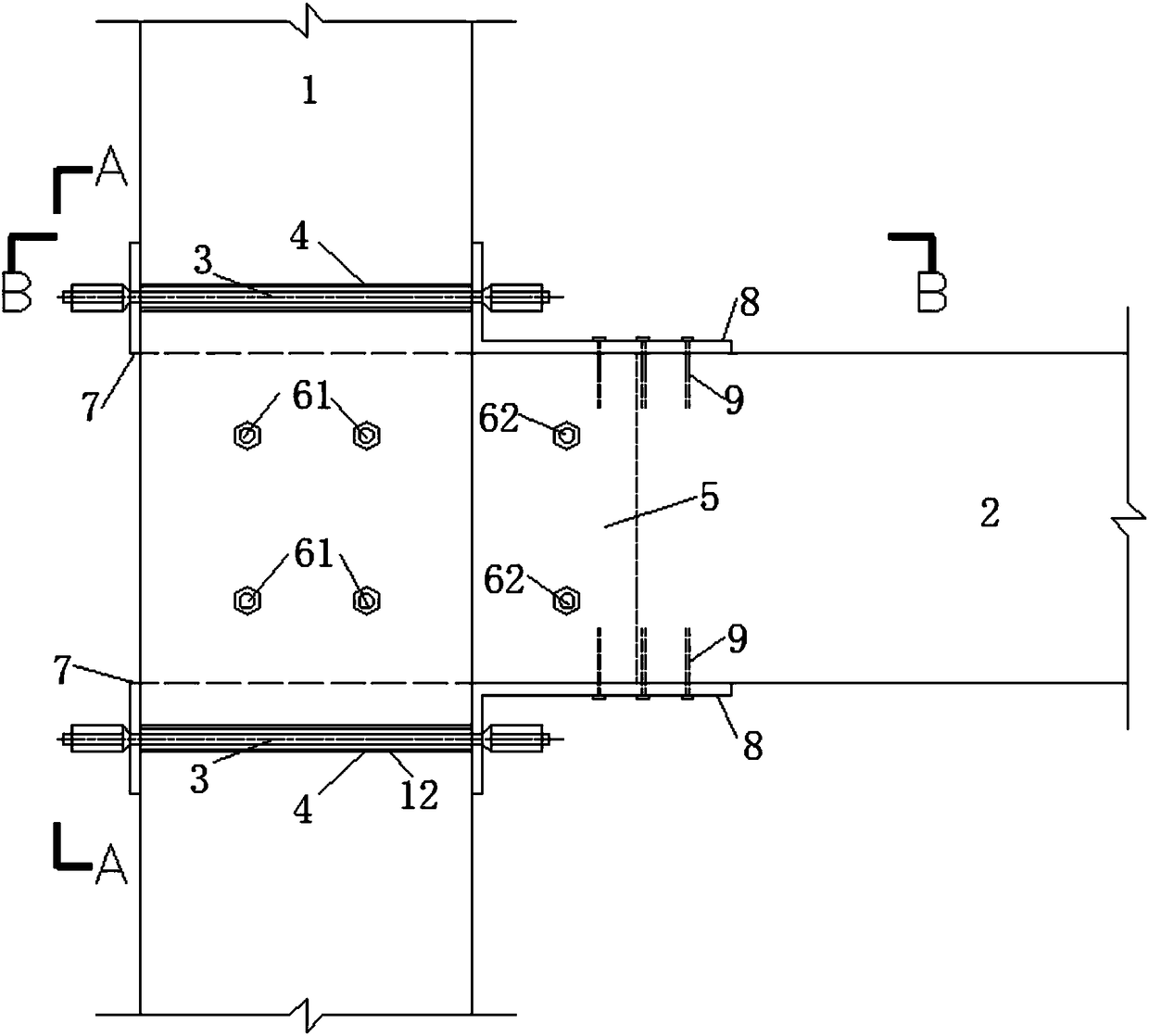

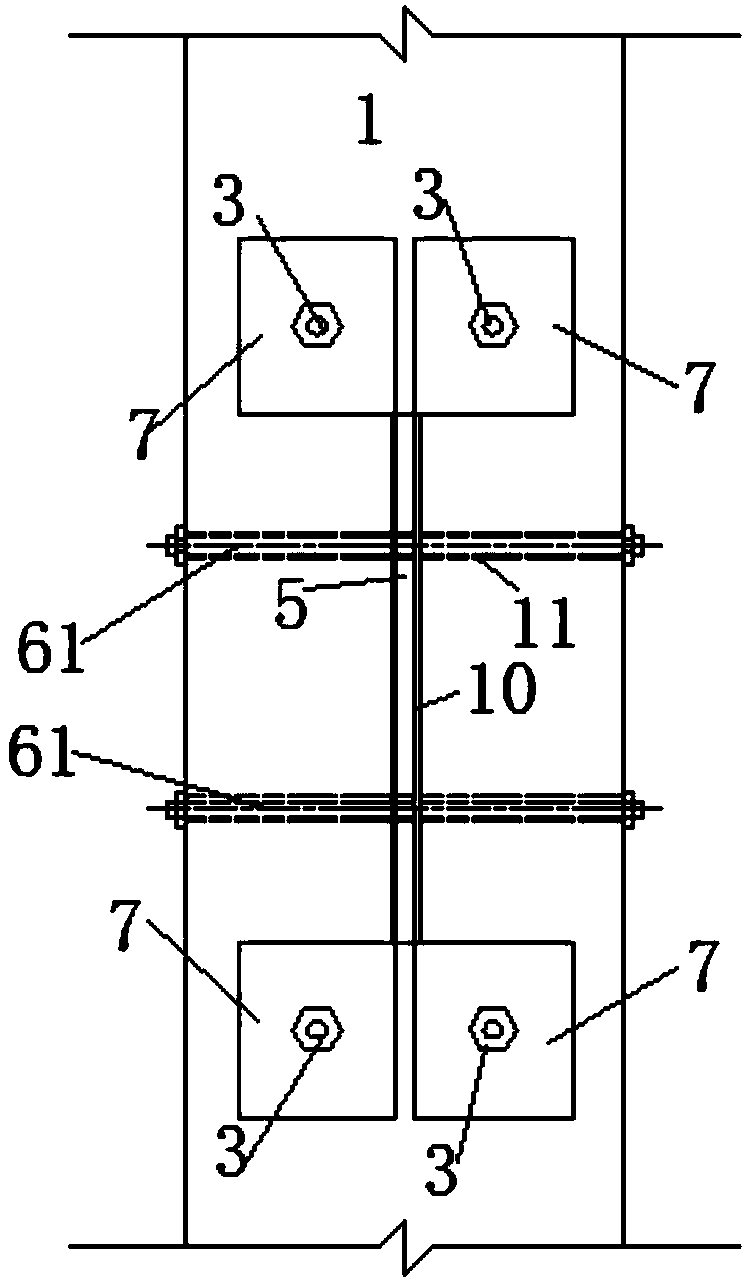

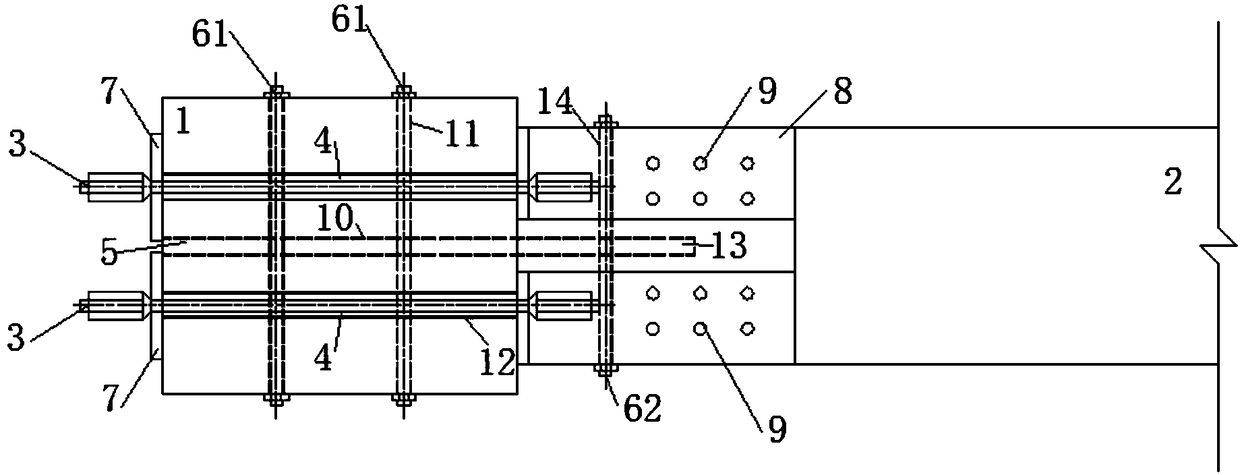

[0037] refer to Figure 1-Figure 3 , a wood frame beam-column self-resetting joint based on shape memory alloy bolts, including a wooden column 1, a wooden beam 2 and a connecting angle steel 8, the wooden column 1 and the wooden beam 2 are vertically arranged, and two connecting angle steels 8 are provided, respectively On the upper and lower sides of the wooden beam 2, and the two sides of the connecting angle steel 8 are respectively close to the wooden column 1 and the wooden beam 2, the self-resetting joints of the wooden frame beam and column also include shape memory alloy self-resetting bolts 3 and embedded steel plates 5, The shape memory alloy self-resetting bolt 3 runs through the wooden column 1, and connects the wooden column 1 with one side of the connecting angle steel 8, and connects the other side of the connecting angle steel 8 with the wooden beam 2 through self-tapping screws 9, and the wooden column 1 is opened inside There is a notch 10 for the wooden col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com