Anti-freezing and braking system cooling device for automobile oil supply system

A technology of fuel supply system and braking system, which is applied in the direction of heat treatment device for fuel, arrangement combined with fuel supply of internal combustion engine, power device, etc., can solve problems such as uneconomical, loss of braking ability, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

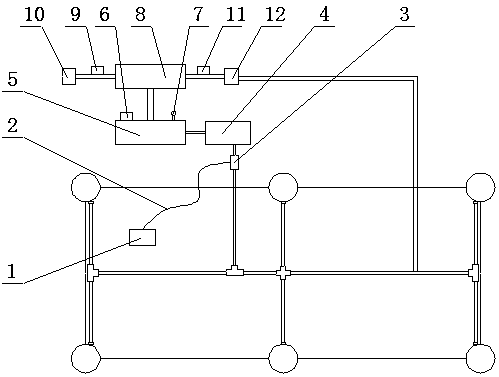

[0016] Such as figure 1 As shown, a device for antifreezing of automobile oil supply system and cooling of brake system, which includes a cold and hot gas generator 4, an air storage tank 5 and a control circuit 2, and the control circuit 2 is connected to the control switch 1 and the solenoid valve 3. The solenoid valve 3 is connected to a cold air generator 4, the cold air generator 4 is connected to an air storage tank 5, and the air storage tank 5 is connected to a cold and hot air generator 8, and the cold and hot air generator 8 A solenoid valve A9 is connected to the fuel tank heater 10 , and the hot and cold air generator 8 is connected to a solenoid valve B11 connected to a brake pad cooler 12 .

[0017] The purpose of this patent is to provide a diesel fuel system that uses hot air to prevent freezing of the fuel system such as the engine oil tank and uses cold air to cool down the brake pads of the car. The cooling device placed on the fuel tank is connected, and t...

Embodiment 2

[0019] Such as figure 1 As shown, a device for antifreezing of automobile oil supply system and cooling of brake system, which includes a cold and hot gas generator 4, an air storage tank 5 and a control circuit 2, and the control circuit 2 is connected to the control switch 1 and the solenoid valve 3. The solenoid valve 3 is connected to a cold air generator 4, the cold air generator 4 is connected to an air storage tank 5, and the air storage tank 5 is connected to a cold and hot air generator 8, and the cold and hot air generator 8 A solenoid valve A9 is connected, the solenoid valve A9 is connected with a fuel tank heater 10, the hot and cold air generator 8 is connected with a solenoid valve B11, and the solenoid valve B11 is connected with a brake pad refrigerator 12, and the hot and cold gas One end of the generator 8 is connected to a hot air pipe, and the other end is connected to a cold air pipe. The connection between the brake pad cooler 12 and the brake pad is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com