Parallel and outer ring staggered type extrusion oil film damper

A technology of squeezing oil film damping and oil film damper, which is applied in the field of damping and vibration reduction, can solve the problems of instability, aggravating the degree of vibration of the rotor system, and difficulty in damping damping, and achieves the effect of reducing the stiffness of the oil film and improving the damping of the oil film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

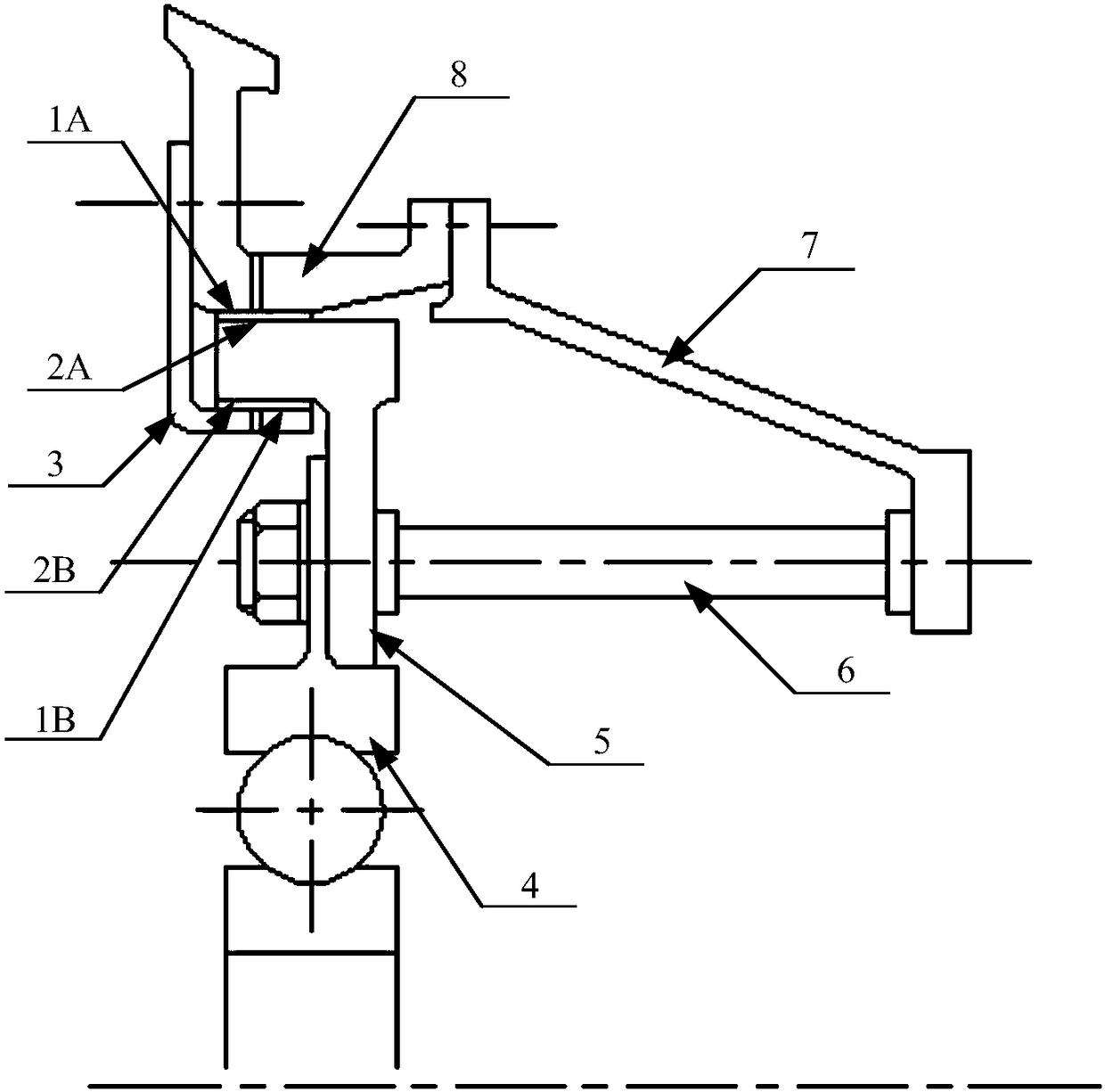

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. In view of the problems existing in the prior art, in this embodiment, a parallel connection with an outer ring misplaced to increase resistance is proposed. Squeeze film dampers such as image 3 As shown, it includes a sleeve 3, a bearing 4, a support 5, a pull rod 6, a bracket 7, a casing 8, an outer oil film oil supply hole 9, an inner oil film oil supply hole 10, and is composed of a casing 8 and a support 5 The outer oil film damper A, the inner oil film damper B composed of the sleeve 3 and the support 5.

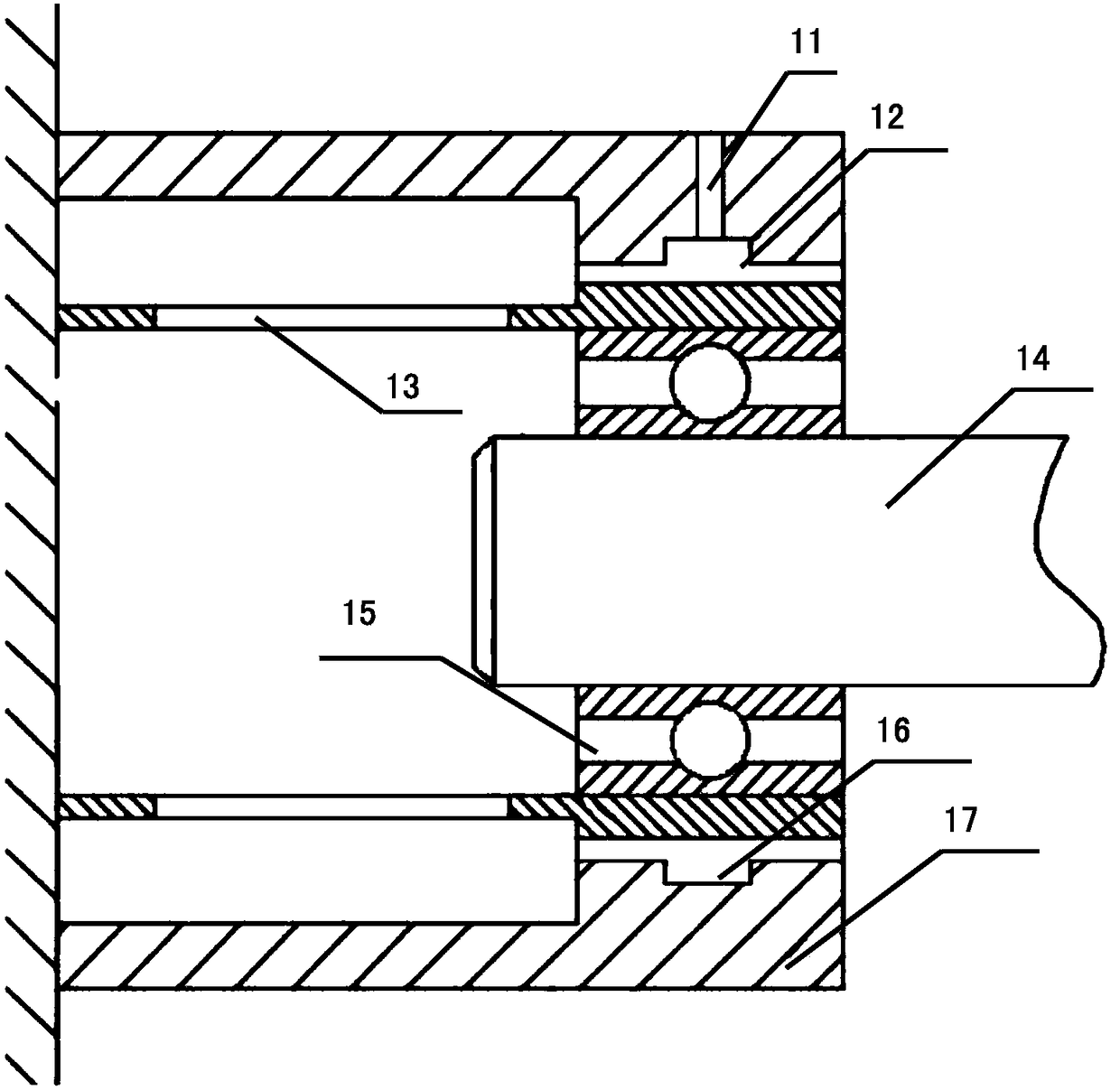

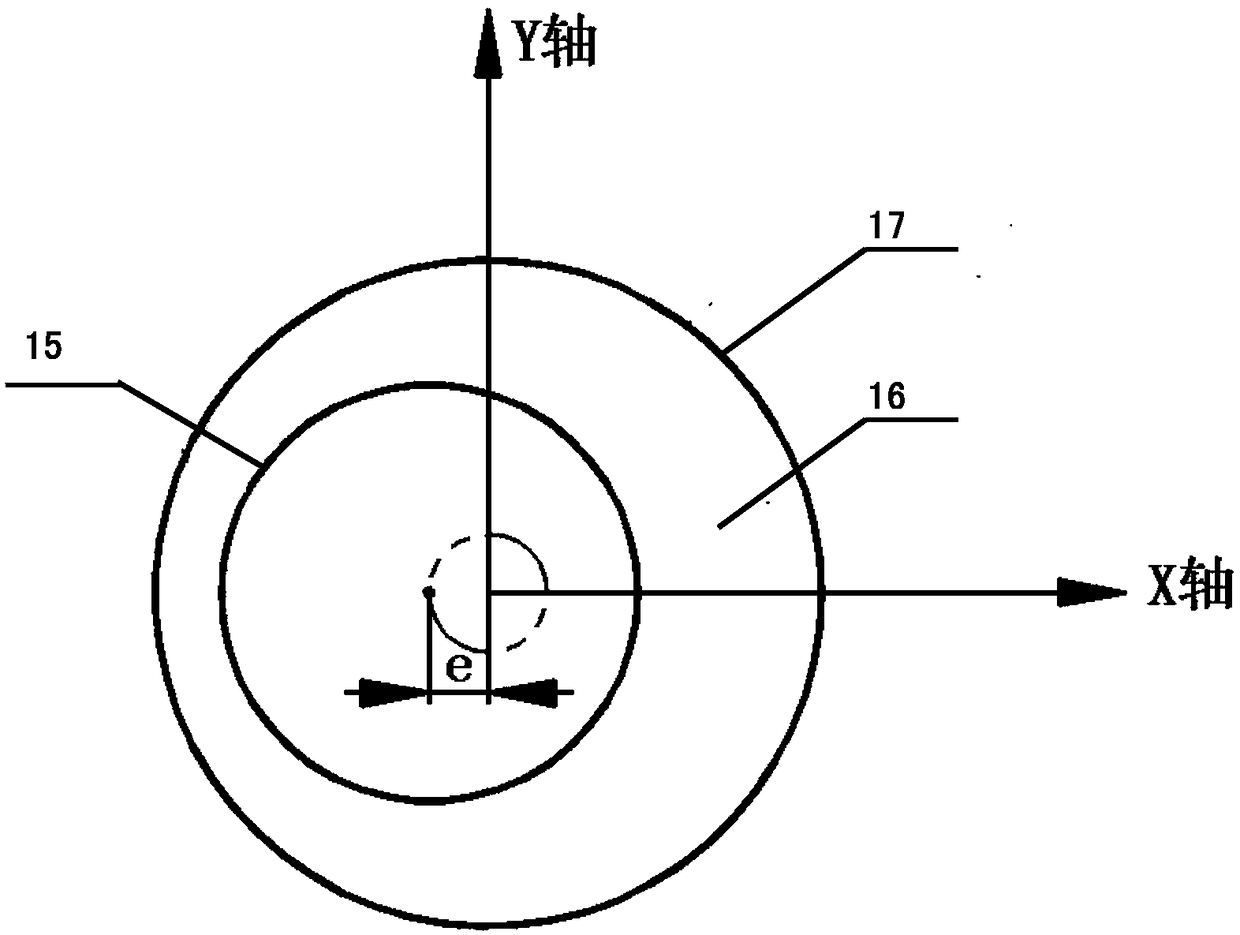

[0017] Such as Figure 4 and Figure 5 As shown, the outer oil film damper A is composed of the oil film filled between the outer oil film damper journal 2A and the outer ring 1A of the outer oil film damper, and the inner oil film damper B is formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com