Intelligent type turnover plate type dual-layer dust discharge valve

A flap-type, intelligent technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of seal impact, short opening and closing time, small opening angle of the ash discharge valve, etc. Accurate and reliable positioning, reducing the effect of system air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

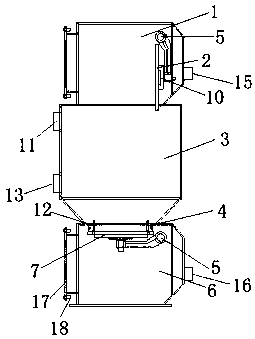

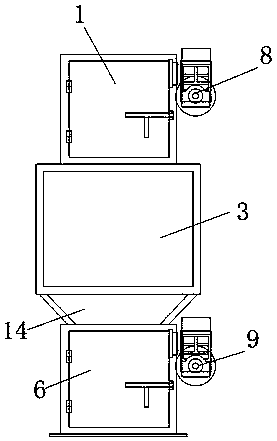

[0021] refer to Figure 1-2 , intelligent flap type double-layer ash unloading valve, including upper valve body 1, lower valve body 6 and middle box body 3, upper and lower valves are equipped with upper valve plate 2 and lower valve plate 7, valve plate drive spindle 5, sealing ring 4 , the outside is equipped with a first driving device 8 and a second driving device 9, the valve plate is a flap structure, the valve plate is turned by an external driving device to realize the switch of the valve plate, the upper and lower valve plates are driven independently, and the second driving device is according to the process requirements 9 drives the valve plate to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com