Negative type thermosensitive CTP plate precursor with double-layer structure

A double-layer structure, negative-type technology, applied in the field of negative-type thermal CTP plate precursors, can solve the problems of insufficient stability of active compounds, influence of negative-type plate storage period, incomplete development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

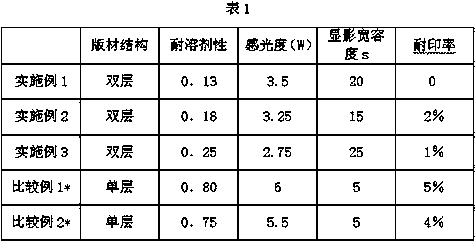

Examples

Embodiment 1

[0060] Production of Negative Thermal Plates

[0061] An aluminum coil in which a 0.30 mm-thick aluminum plate (support) was curled into a roll (coil) was fixed to a feeder. In the surface treatment part, 10% sodium hydroxide is used to immerse the aluminum plate continuously sent out from the sender at 70°C for 60 seconds, after etching, wash it with running water, and wash it with 20% HN0. 3 Perform neutralization washing and water washing. Under the condition of VA=12.7V, use the alternating waveform current of sine wave, in 1% nitric acid aqueous solution at 300 coulomb / dm 2 The electrolytic surface roughening treatment is carried out on the electric current of the anode. The surface roughness thereof was measured and found to be 0.6 μm (expressed as Ra).

[0062] followed by immersion in 30% H 2 SO 4 In aqueous solution, after decontamination at 55°C for 2 minutes, at 33°C in 20% H 2 SO 4 In the aqueous solution, the cathode is arranged on the frosted surface, and ...

Embodiment 2

[0090] In Example 1, except that the composition of the coating solution for the alkali-soluble resin layer was changed, a negative-working thermal plate was manufactured in the same manner as in Example 1.

[0091] (alkali-soluble resin layer)

[0092] N, N-dimethylformamide (DMF) 6 parts by weight

[0093] 2 parts by weight of water

[0094] 25 parts by weight of ethyl cellosolve

[0095] PVB modified resin (Diversitec corporation, DT-5) 1.5 parts by weight

[0096] Youlan 603 (Beijing Chemical Plant) 0.07 parts by weight

[0097] BYK-307 Polyethoxylated Dimethicone Copolymer

[0098] (BYK Chemie, Wallingford, CT, USA) 0.0035 parts by weight

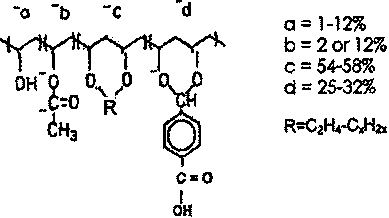

[0099] The structural formula of DT-5 is as follows:

[0100]

Embodiment 3

[0102] In Example 3, a positive-working lithographic printing plate was produced in the same manner as in Example 1, except that the composition of the alkali-soluble resin layer coating solution was changed.

[0103] (alkali-soluble resin layer)

[0104] N, N-dimethylformamide (DMF) 6 parts by weight

[0105] 2 parts by weight of water

[0106] 25 parts by weight of ethyl cellosolve

[0107] Novolac resin BTB29 resin (Weihai Tiancheng Chemical Co., Ltd.) 1.3 parts by weight

[0108] Tert-butylphenol phenolic resin (SP-1077, Lucky Huaguang Printing Technology Co., Ltd.) 0.3 parts by weight

[0109] Polyurethane resin 5715 (Novoon, USA) 0.5 parts by weight

[0110] Youlan 603 (Beijing Chemical Plant) 0.07 parts by weight

[0111] BYK-307 Polyethoxylated Dimethicone Copolymer

[0112] (BYK Chemie, Wallingford, CT, USA) 0.0035 parts by weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com