Antistatic high-strength electrical shielding data cable

一种数据电缆、高强度的技术,应用在绝缘电缆、可弯曲的电缆、缆等方向,能够解决抗干扰性能下降、易产生静电、信号干扰等问题,达到提高性能可靠性和安全性、减少静电的产生、结构变化影响低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

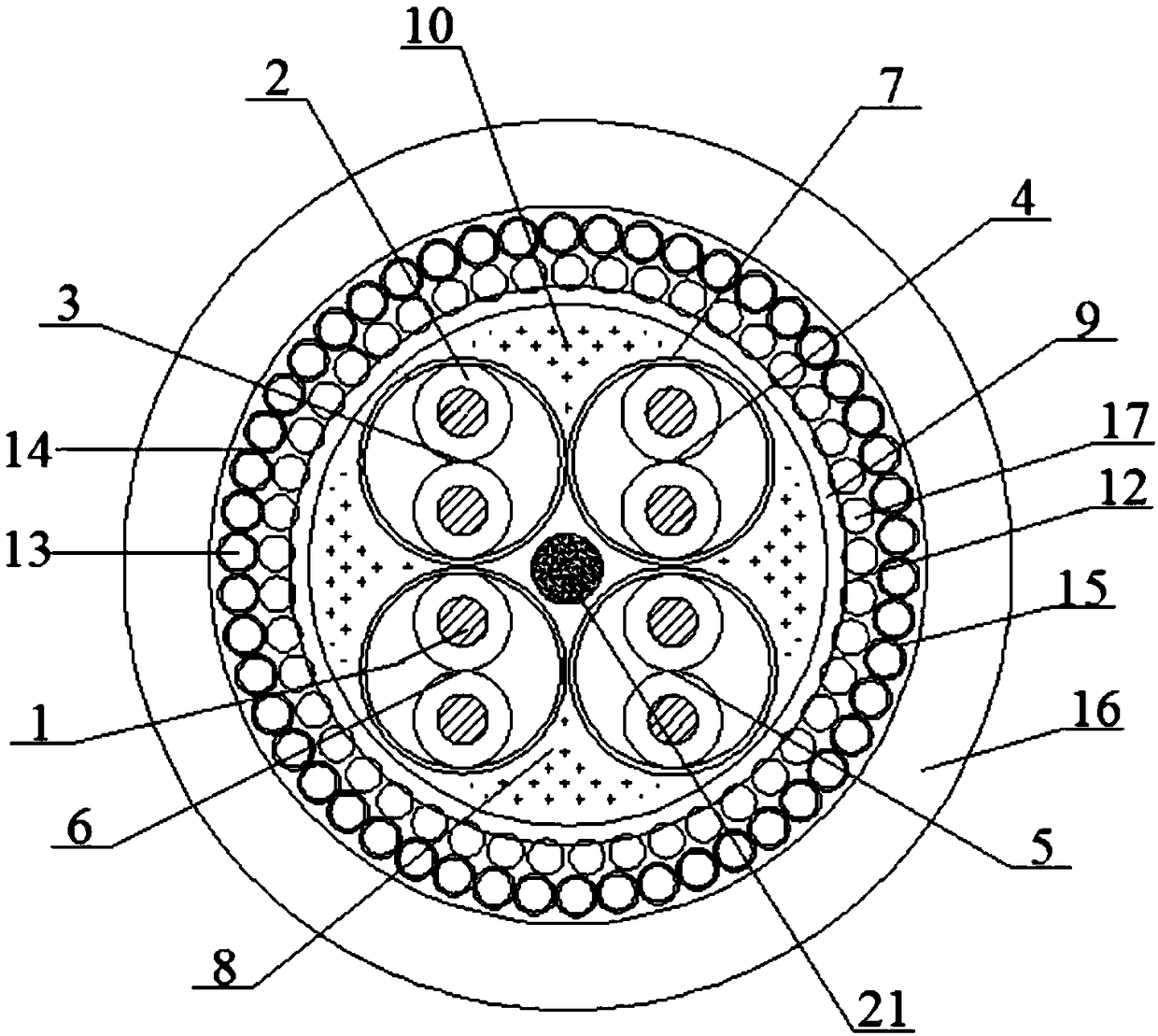

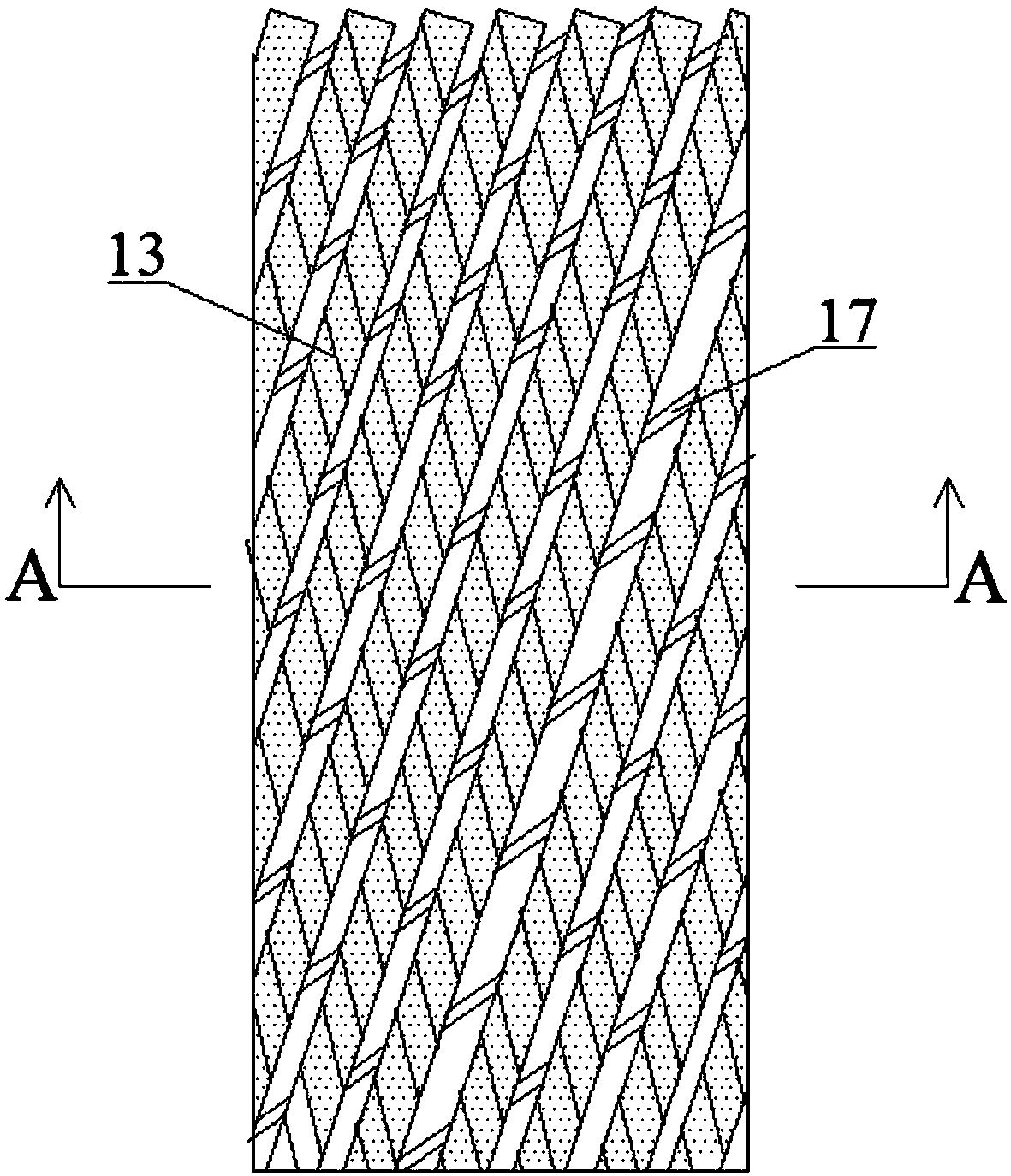

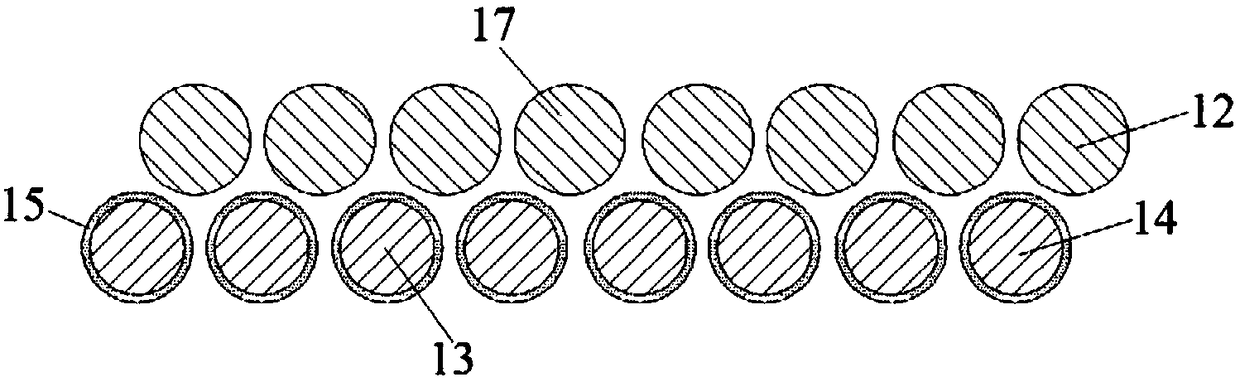

[0025] Embodiment: An antistatic high-strength electric shielded data cable, comprising: eight copper conductor units 1 and aramid reinforcement 21. The outer surface of the copper conductor unit 1 is covered with an insulating polypropylene layer 2. The copper conductor unit 1 Including an aramid fiber 20 in the center, an inner conductive layer composed of a number of first copper wires 22 twisted on the outer surface of the aramid fiber 20, and a number of second copper wires 23 twisted on the outer surface of the inner conductive layer Form the outer conductor layer;

[0026] The eight copper conductor units 1 are twisted in pairs to form the first, second, third, and fourth symmetrical insulated wire pairs 3, 4, 5, 6 and the outer surfaces of each are wrapped with a first polytetrafluoroethylene tape 7. The first, second, third and fourth symmetric insulated wire pairs 3, 4, 5, 6 are twisted on the outer surface of the aramid reinforcement 21 to form a cable core 8;

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com