Three-phase high-frequency transformer

A three-phase high-frequency, transformer technology, applied in the direction of fixed transformer or mutual inductance, transformer/inductor core, transformer/inductor components, etc. Large difference in resistance and other problems, to achieve the effect of small occupied space, low manufacturing cost, and balanced magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

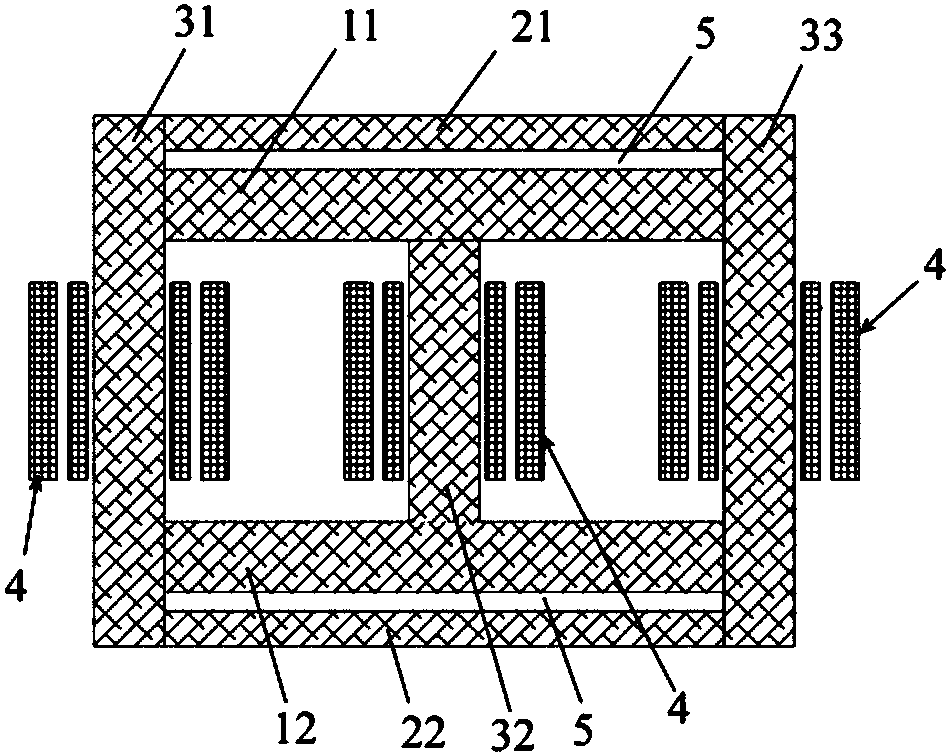

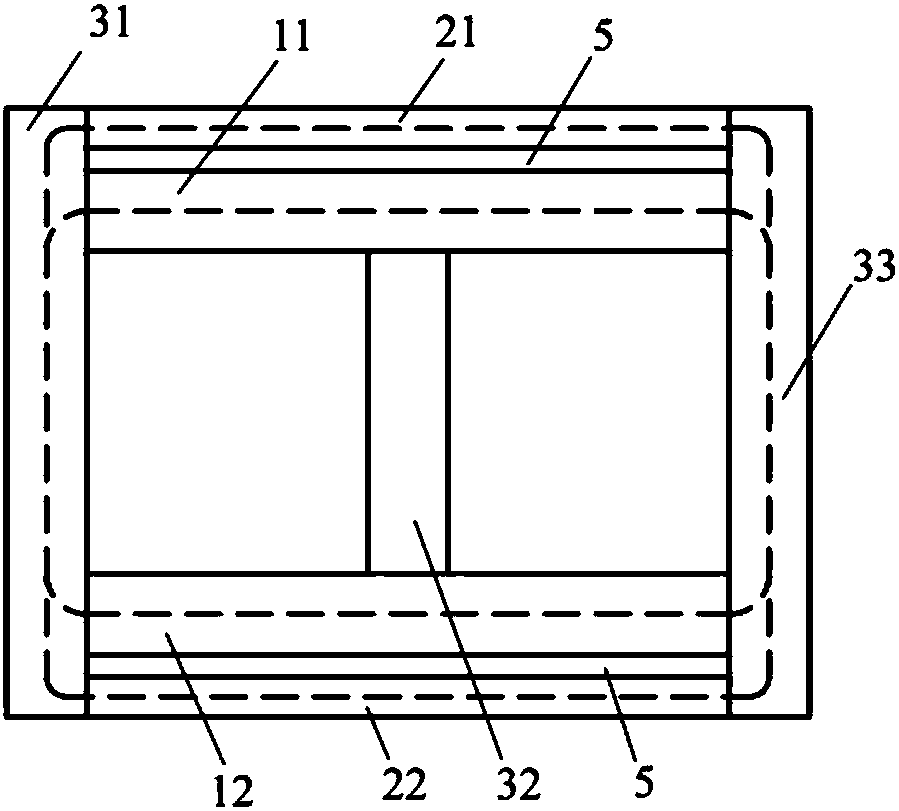

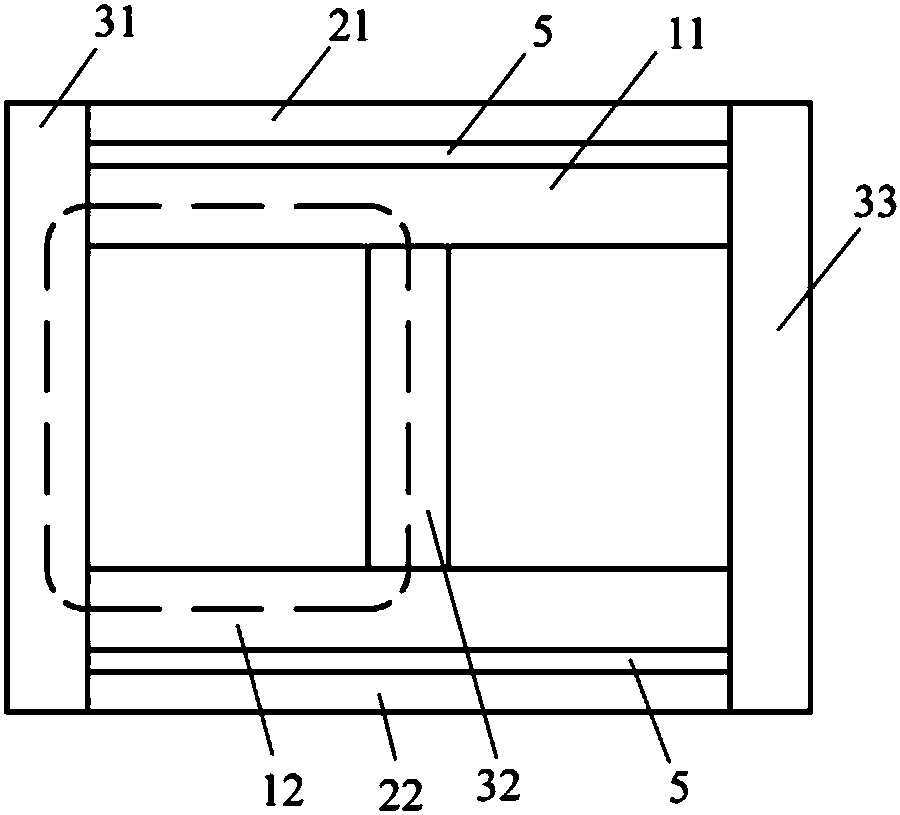

[0022] Such as figure 1 The three-phase high-frequency transformer shown includes: an upper main iron yoke 11, a lower main iron yoke 12, an upper auxiliary iron yoke 21, a lower auxiliary iron yoke 22, an iron core column 31, an iron core column 32, and an iron core column 33 . Among them, the upper main iron yoke 11, the lower main iron yoke 12, the upper auxiliary iron yoke 21, and the lower auxiliary iron yoke 22 are silicon steel yokes, amorphous / nanocrystalline iron yokes or ferrite magnetic powder iron yokes, the iron core column 31, the iron core Column 32 and core column 33 are silicon steel core columns, amorphous / nanocrystalline core columns or ferrite magnetic powder core columns.

[0023] The iron core column 31 and the iron core column 33 are arranged on both sides, and the iron core column 32 is arranged in the middle, and each iron core column is wound with a coil 4, including a primary coil and a secondary coil, and three primary coils on three iron core colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com