Motor rotating shaft and magnetic levitation motor

A technology of motor shaft and magnetic suspension bearing, which is applied to magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of increasing the control difficulty of magnetic suspension bearings, reducing the control accuracy of magnetic suspension bearings, and reducing bearing output, so as to reduce the control accuracy and control difficulty. , Improve working performance, improve the effect of bearing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

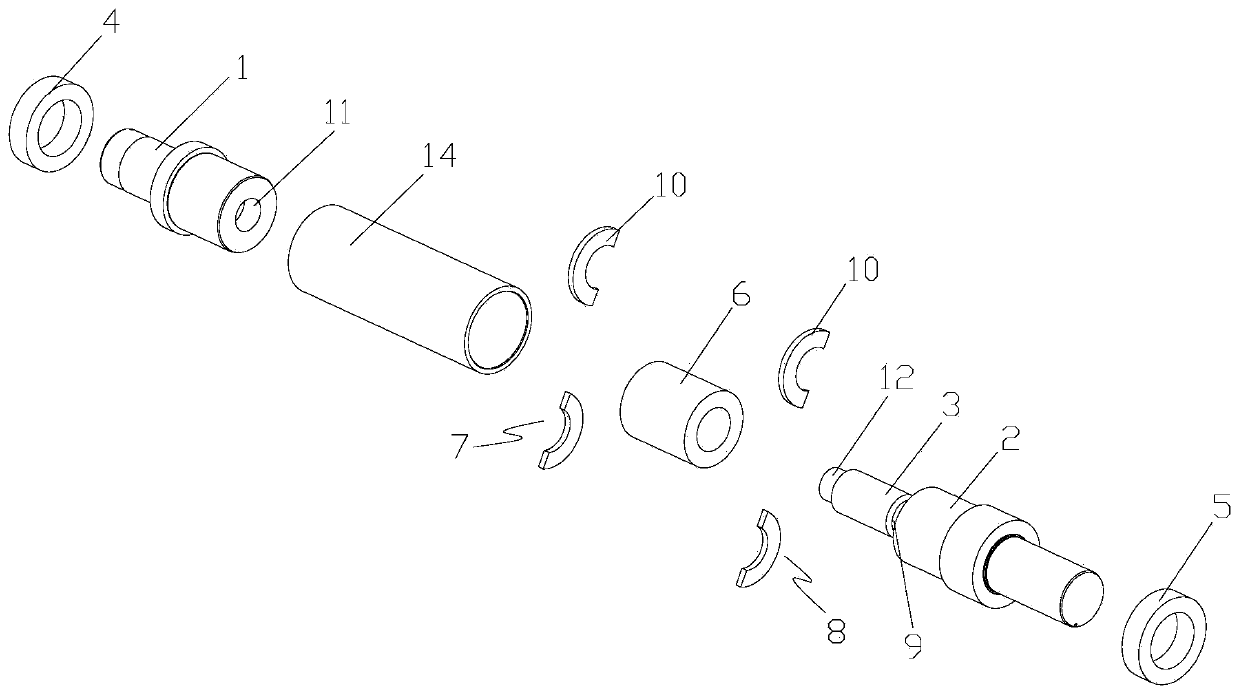

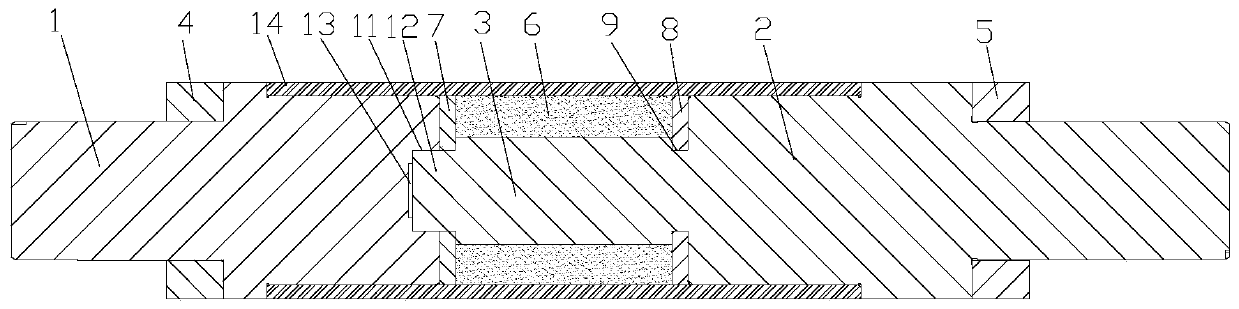

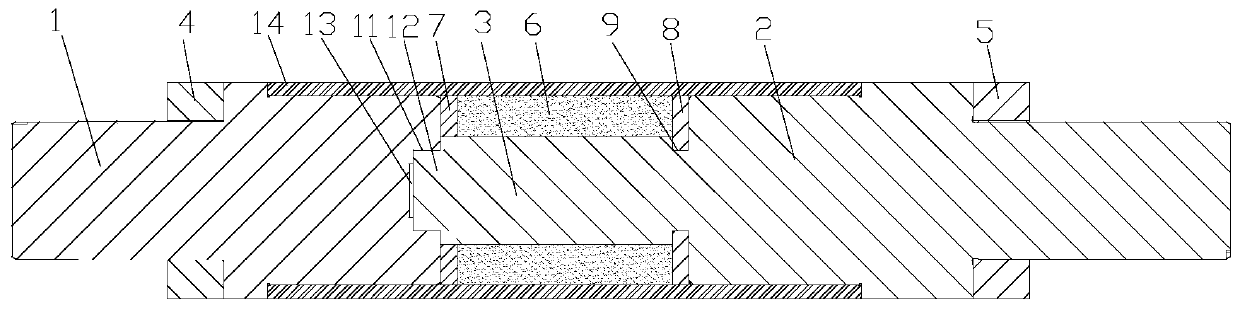

[0026] See also Figure 1 to Figure 4 As shown, according to the embodiment of the present application, the motor shaft includes a front stub shaft 1, a rear stub shaft 2, a core shaft 3, a front magnetic bearing 4, a rear magnetic bearing 5, a magnetic steel ring 6, a first magnetic isolation ring 7 and a first Two magnetic isolation rings 8, the core shaft 3 is set between the front stub shaft 1 and the rear stub shaft 2, the front magnetic suspension bearing 4 is sleeved on the front stub shaft 1, and the rear magnetic suspension bearing 5 is sleeved on the rear stub shaft 2. The steel ring 6 is sleeved outside the mandrel 3, the first magnetic isolation ring 7 and the second magnetic isolation ring 8 are sleeved outside the mandrel 3, and the magnetic steel ring 6 is located on the first magnetic isolation ring 7 and the second magnetic isolation ring 8. In between, the front stub shaft 1 and / or the rear stub shaft 2 are made of magnetically conductive materials. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com