An aluminum-air battery system and its working method

A technology of aluminum-air battery and working method, which is applied in the direction of fuel cell, fuel cell additive, fuel cell-type half-cell and primary battery-type half-cell, etc., and can solve the problem of difficult removal of reaction products and large consumption of electrolyte, etc. problem, to achieve the effect of increasing the specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

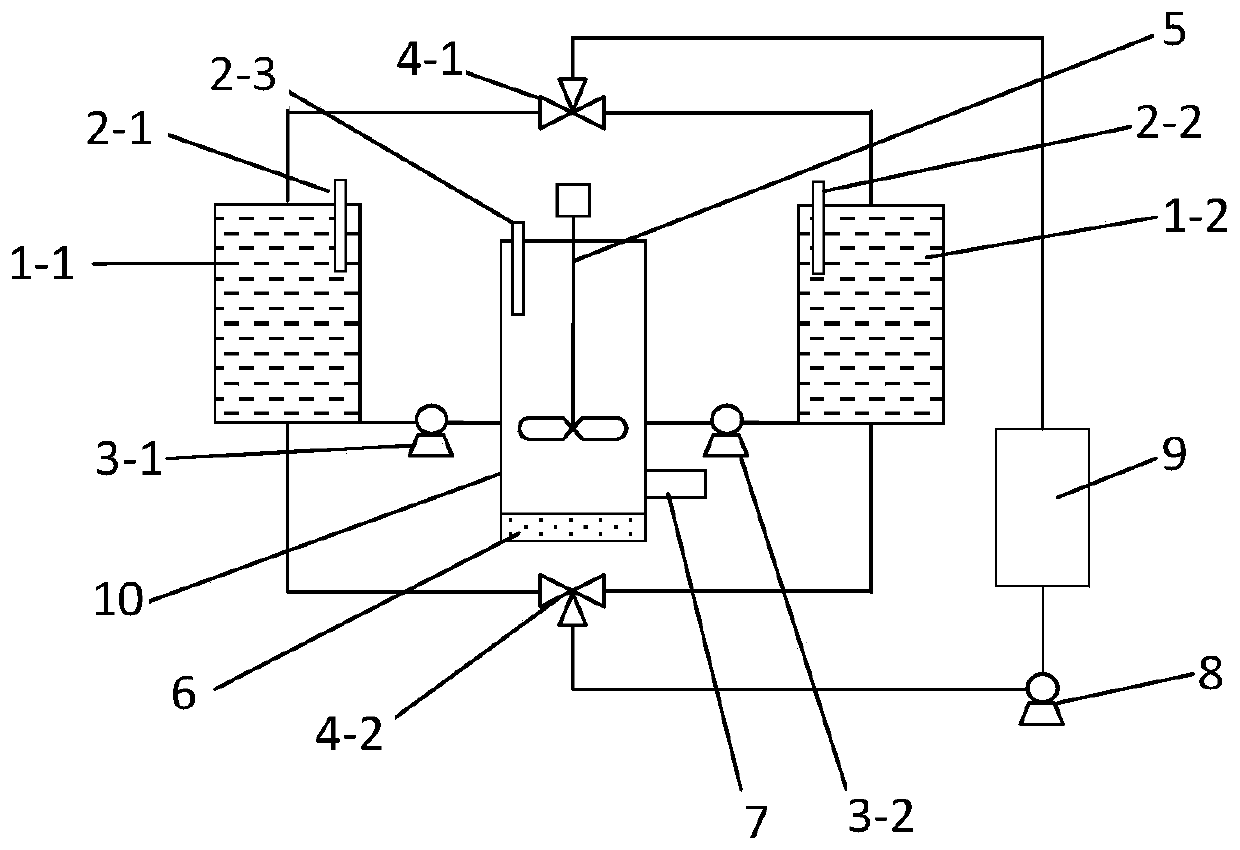

[0035] An aluminum-air battery system such as figure 1As shown, it includes an aluminum-air battery pack 9, two electrolyte storage chambers (1-1 and 1-2) and a product separation chamber 10; the battery pack includes 23 single cells, and the thickness of the aluminum anode plate is 15mm; the The two electrolyte storage chambers are respectively equipped with 50 L of 8 mol / L potassium hydroxide solution; the product separation chamber is equipped with aluminum hydroxide seeds with an average particle size of 1 micron.

[0036] The working process of the aluminum-air battery is as follows: start the aluminum-air battery system, the state of the three-way valve 4-1 and 4-2 makes the first electrolyte storage chamber and the battery pack form an electrolyte circuit, and the aluminum-air battery starts to output electric energy. When the conductivity sensor in the first electrolyte storage chamber detects that the conductivity of the electrolyte is lower than 150ms / cm, the three-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com