Lead storage battery recycling device

A technology for recycling and processing lead-acid batteries, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as leakage damage, pollution, etc., and achieve the effect of effective recycling and reduction of pollution damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

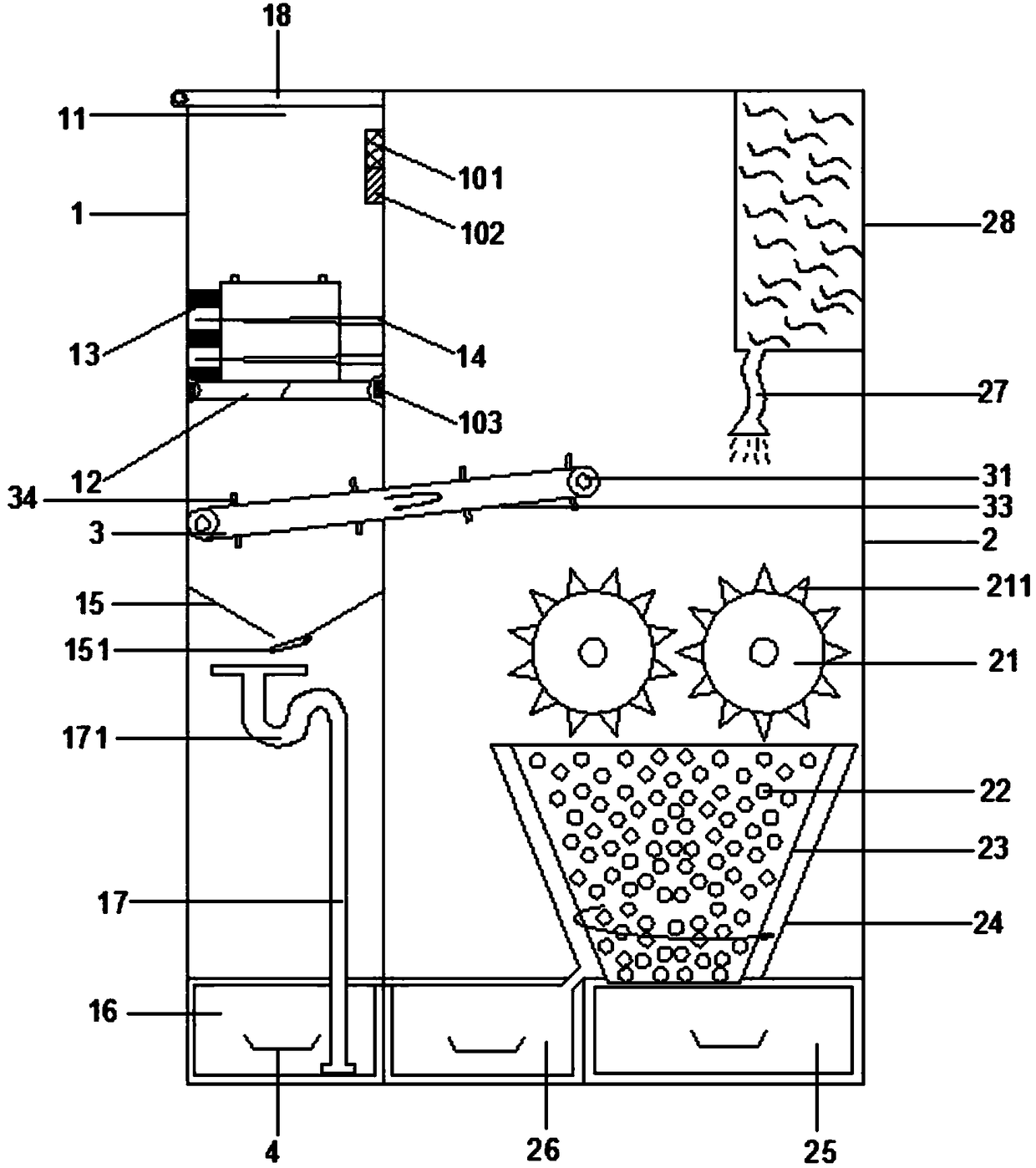

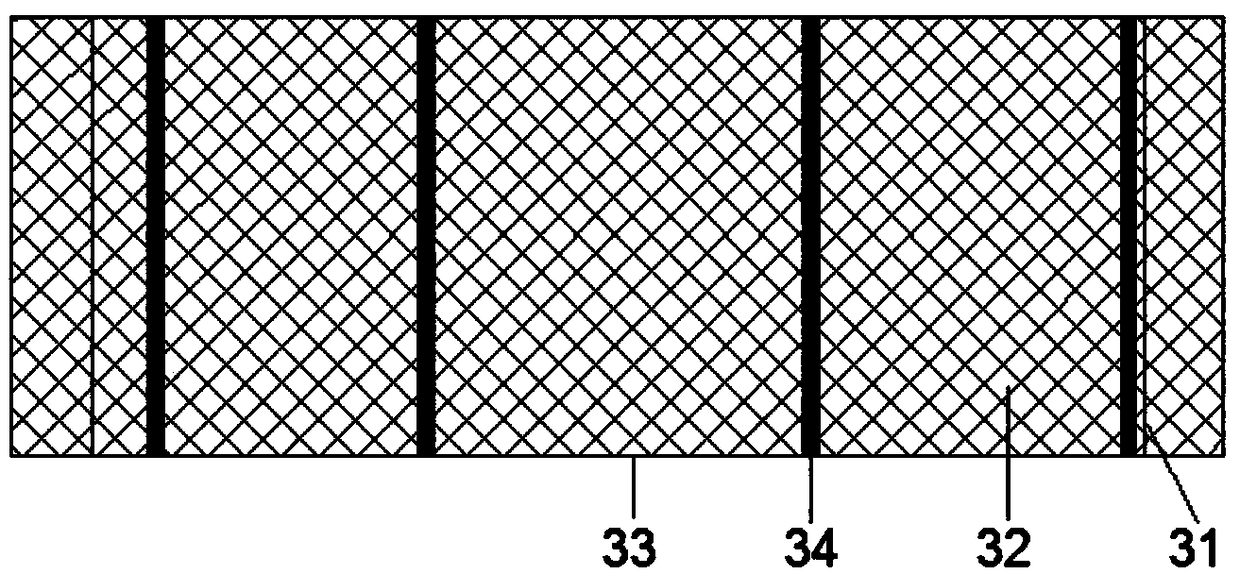

[0021] A lead storage battery recycling and processing device, comprising a sulfuric acid collection chamber 1 and a lead paste collection chamber 2 connected side by side; an opening 11 is provided above the sulfuric acid collection chamber 1; The load-bearing plate 12; the two sides above the load-bearing plate are respectively provided with a support block 13 and a cutting edge 14; the support block 13 is fixed on the inner wall of the sulfuric acid collection chamber 1; the cutting edge 14 and the load-bearing plate 12 pass through the The system is electrically connected, and the cutting blade 14 can be automatically extended and retracted according to the weight on the load-bearing plate 12; Closing module 103; the transfer module 101 can receive the weight information detected by the opening and closing module 103, and feed back inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com