Artificial graphite film applied to unmanned aerial vehicle control chip end cap

A technology for controlling chips and artificial graphite, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. problems such as decline, to achieve the effect of good heat dissipation performance, improved safety performance and service life

Inactive Publication Date: 2018-06-29

安徽碳华新材料科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

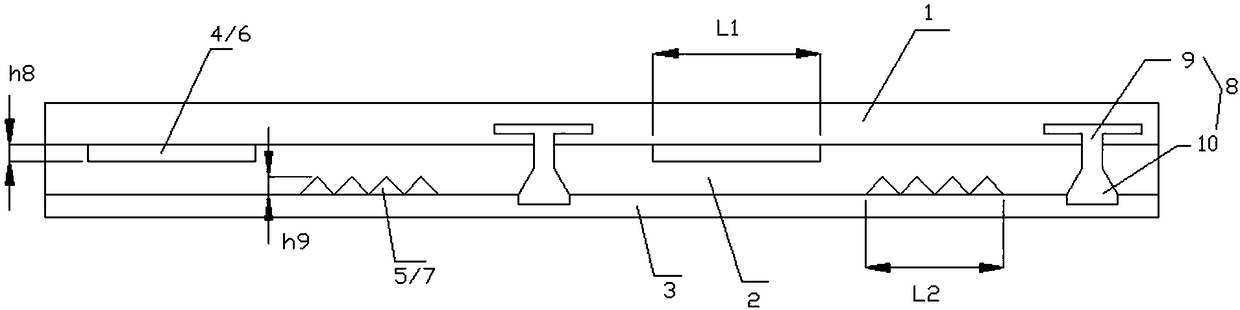

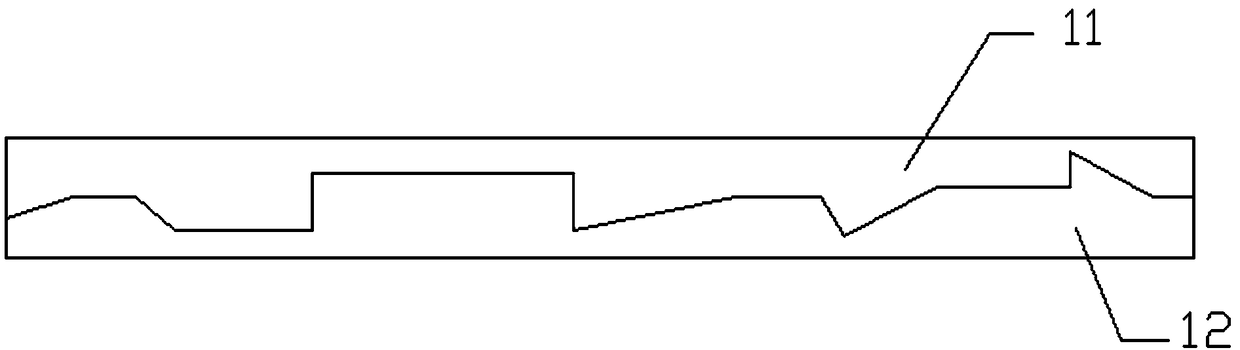

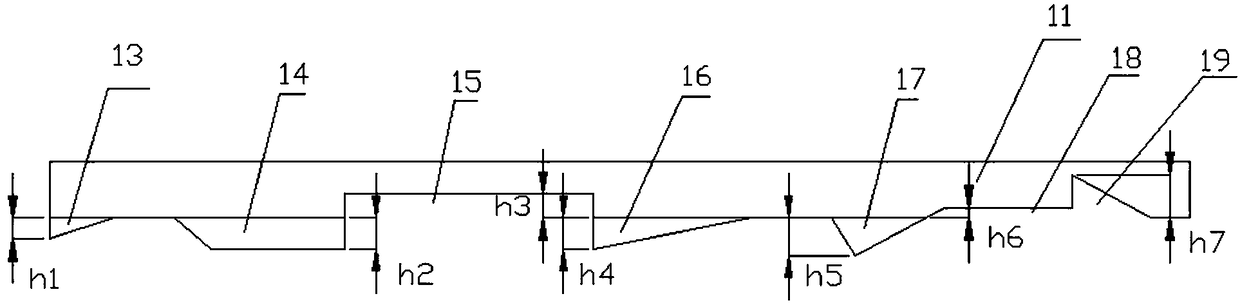

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an artificial graphite film applied to an unmanned aerial vehicle control chip end cap. A preparation method of the artificial graphite film includes: (1), using polyimide filmsas a raw material, mutually stacking at least 5-8 layers of the polyimide films, arranging a graphite piece between each two adjacent polyimide films in a fitted manner, and arranging a graphite piece outside the polyimide film at each of the top end and the bottom end in a fitted manner; (2), putting the polyimide films in a carbonizing furnace for carbonizing after being stacked through the step (1), and transferring a carbonized material into a graphitizing furnace for graphitizing to obtain a single graphite film; (3), repeating the steps (1) and (2) for 8-12 times; (4), mutually stackinga plurality of the single graphite films prepared repeatedly, putting the stacked single graphite films in a high-temperature furnace, applying pressure of 5-10N on the stacked single graphite films,holding temperature of 1200 DEG C for 2-4h, and naturally cooling to obtain the artificial graphite film. The artificial graphite film has good heat-radiating performance, and safety is improved while service life is prolonged.

Description

technical field [0001] The invention relates to an artificial graphite film, in particular to an artificial graphite film applied to the end cover of a control chip of an unmanned aerial vehicle. Background technique [0002] At present, UAV technology has achieved unprecedented development. People have already applied drones in aerial photography, weather monitoring, agriculture and other fields. The main control chip of the existing unmanned aerial vehicle is highly integrated, and the area of the entire printed circuit board (PCB for short) is small. When the drone is working, the main control chip of the drone needs to perform a lot of calculations, which consumes a lot of power and generates a lot of heat. At the same time, a wireless network (Wireless-Fidelity, Wi-Fi for short) chip or module integrated on the PCB also consumes relatively high power consumption and generates a huge amount of heat. In addition, because the current PCB generally adopts a large-area ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K7/20

CPCH05K7/205

Inventor 陈玲杨源

Owner 安徽碳华新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com