Robot spot welding tool and method for antenna array

An antenna element and robot technology, which is applied to welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of poor welding consistency, low welding efficiency, and low yield of antenna elements, so as to improve welding quality and efficiency and improve welding efficiency. , the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

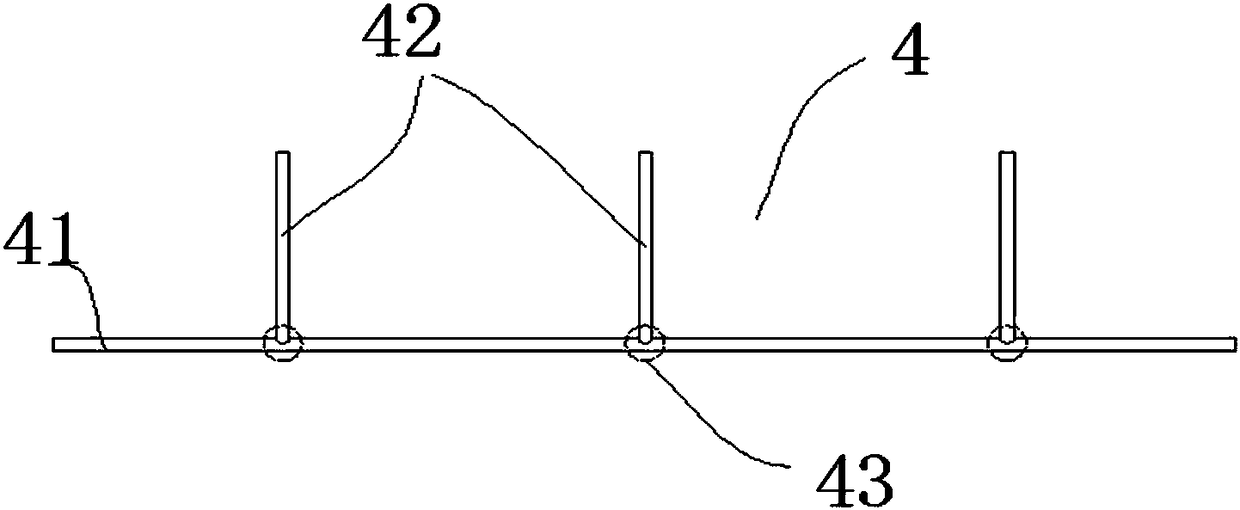

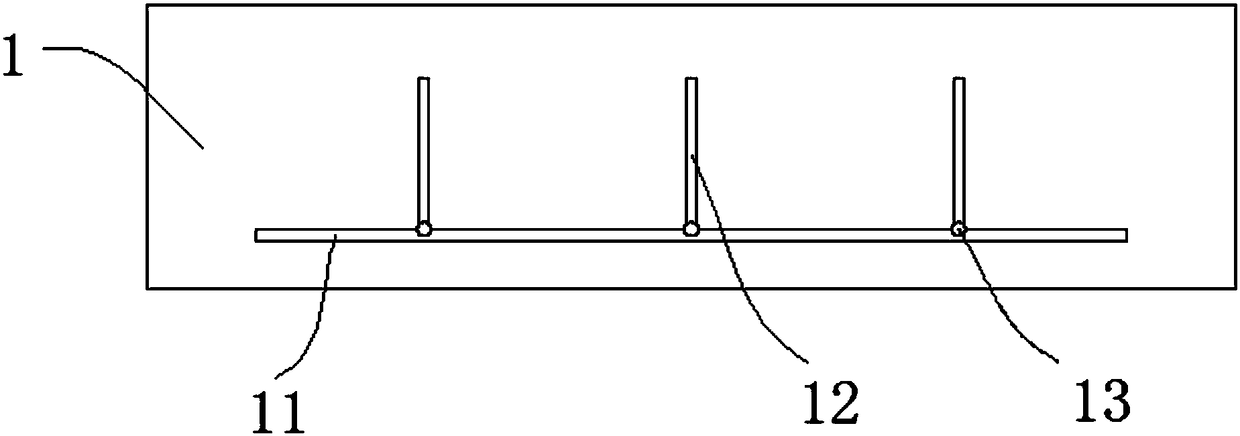

[0034] combined with figure 1 with figure 2 , a robot spot welding tool for an antenna element in the present invention, including a bottom plate 1 for limiting the antenna element, the bottom plate 1 is provided with a long circular groove 11 and a plurality of short circular grooves 12, and the long circular groove 11 is used to place the length of the antenna element 4 The rod 41 and the short circular groove 12 are used to place the short rod 42 of the antenna array 4, the positions of the long circular groove 11 and several short circular grooves 12 correspond to the positions of the long rod 41 and the short rod 42 in the antenna array 4, and the short circular groove 12 One end communicates with the oblong groove 11.

Embodiment 2

[0036] combined with figure 2 , a robot spot welding tool for an antenna array in the present invention, the difference from Embodiment 1 is that the connection between the short circular groove 12 and the long circular groove 11 is provided with a circular groove 13, that is, the short rod 42 and the long rod 41 are embedded respectively The corresponding welding place behind the short round groove 12 and the long round groove 11 is aimed at after the long rod and the short rod are welded on one side, and the welding spot in the welding area after turning over does not hinder the welding accuracy after turning over.

Embodiment 3

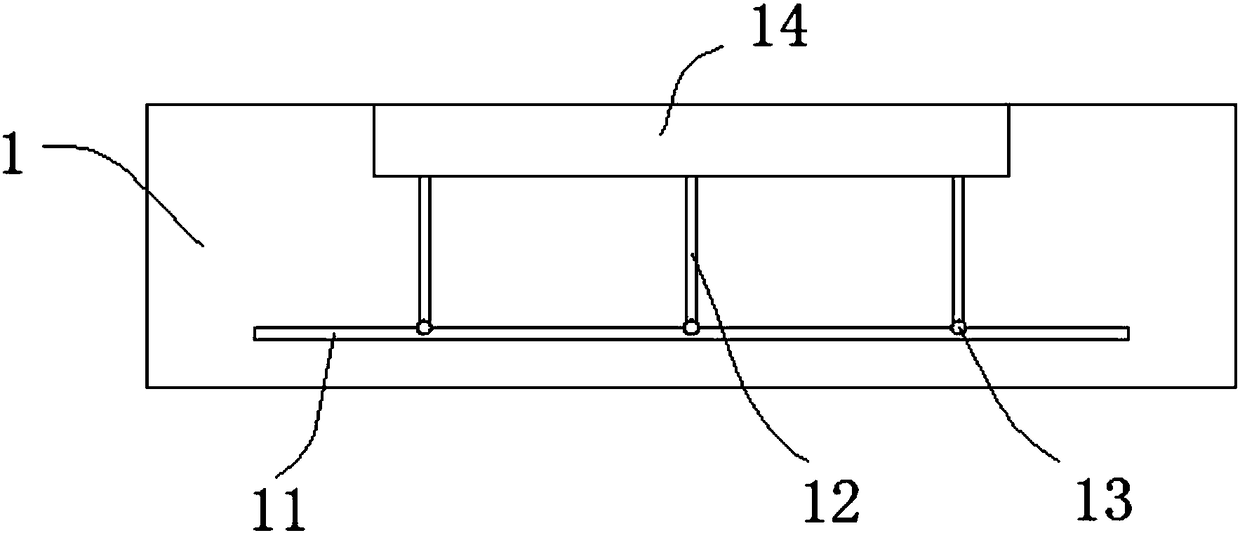

[0038] combined with image 3 with Figure 4 , the robot spot welding frock of a kind of antenna element of the present invention, the difference with embodiment 2 is, also comprises top plate 2, is also provided with side groove 14 on bottom plate 1, one side of side groove 14 and the other side of short circular groove 12 One end is connected, the long rod 41 is placed in the long circular groove 11, the short rod 42 is placed in the short circular groove 12, and the top plate 2 is installed in the side groove 14. Specifically, the top plate 2 is embedded in the side groove 14, and the bottom of the top plate 2 Press the welding point of the short rod 42 and the long rod 41 tightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com