Production device of propylene glycol alginate stabilizer

A technology of propylene glycol alginate and production device, which is applied in the field of compound synthesis device and can solve complex problems and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

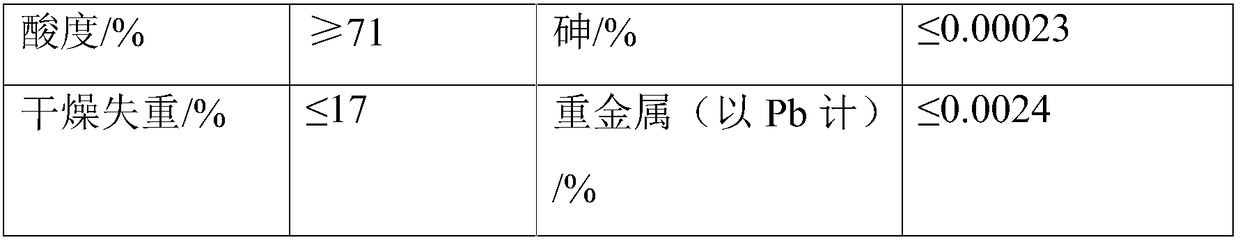

example 1

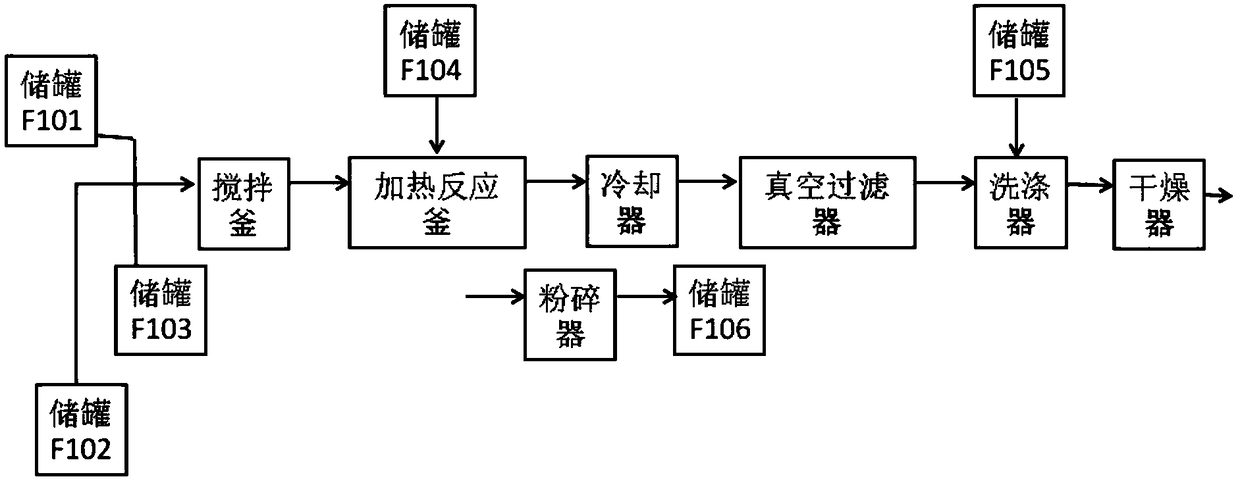

[0008] The production equipment of propylene glycol alginate stabilizer mainly includes: storage tank F101, storage tank F102, storage tank F103, storage tank F104, storage tank F105, storage tank F106, stirring tank, heating reaction tank, cooler, vacuum filter , scrubber, dryer, pulverizer, wherein, the storage tank F101 is used for storing alginic acid, the storage tank F102 is used for storing sodium alginate, the storage tank F103 is used for storing calcium alginate, and the storage tank F104 is used for storing propylene oxide , storage tank F105 is used to store acetone, and storage tank F106 is used to store finished products. Among them, the stirring tank is connected with storage tank F101, storage tank F102, storage tank F103 and heating reaction kettle respectively, and the scrubber is connected with vacuum filter and storage tank respectively. The tank F105 is connected with the dryer, among which, the nominal volume of the stirred tank is 360L, the cylinder diame...

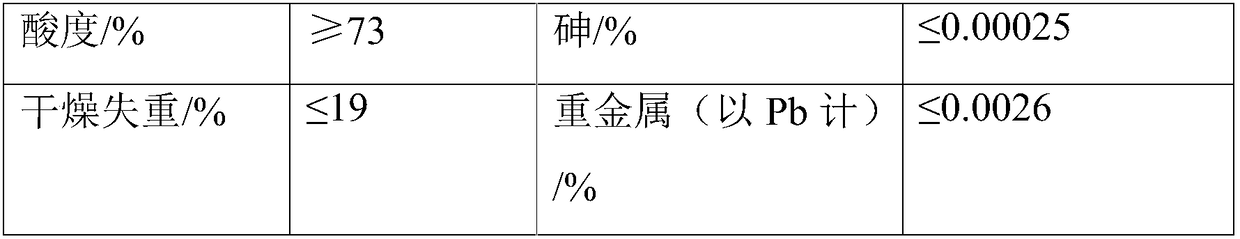

example 2

[0012] The production equipment of propylene glycol alginate stabilizer mainly includes: storage tank F101, storage tank F102, storage tank F103, storage tank F104, storage tank F105, storage tank F106, stirring tank, heating reaction tank, cooler, vacuum filter , scrubber, dryer, pulverizer, wherein, the storage tank F101 is used for storing alginic acid, the storage tank F102 is used for storing sodium alginate, the storage tank F103 is used for storing calcium alginate, and the storage tank F104 is used for storing propylene oxide , storage tank F105 is used to store acetone, and storage tank F106 is used to store finished products. Among them, the stirring tank is connected with storage tank F101, storage tank F102, storage tank F103 and heating reaction kettle respectively, and the scrubber is connected with vacuum filter and storage tank respectively. The tank F105 is connected with the dryer, among which, the nominal volume of the stirred tank is 390L, the cylinder diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap