Detachable supporting device and method for crossing hole

A technology of a supporting device and a supporting method, which is applied to the on-site preparation of building components, the connection of formwork/template/work frame, and construction, etc. Construction costs and other issues, to achieve the effect of reducing material and labor input, convenient construction, and simplifying on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

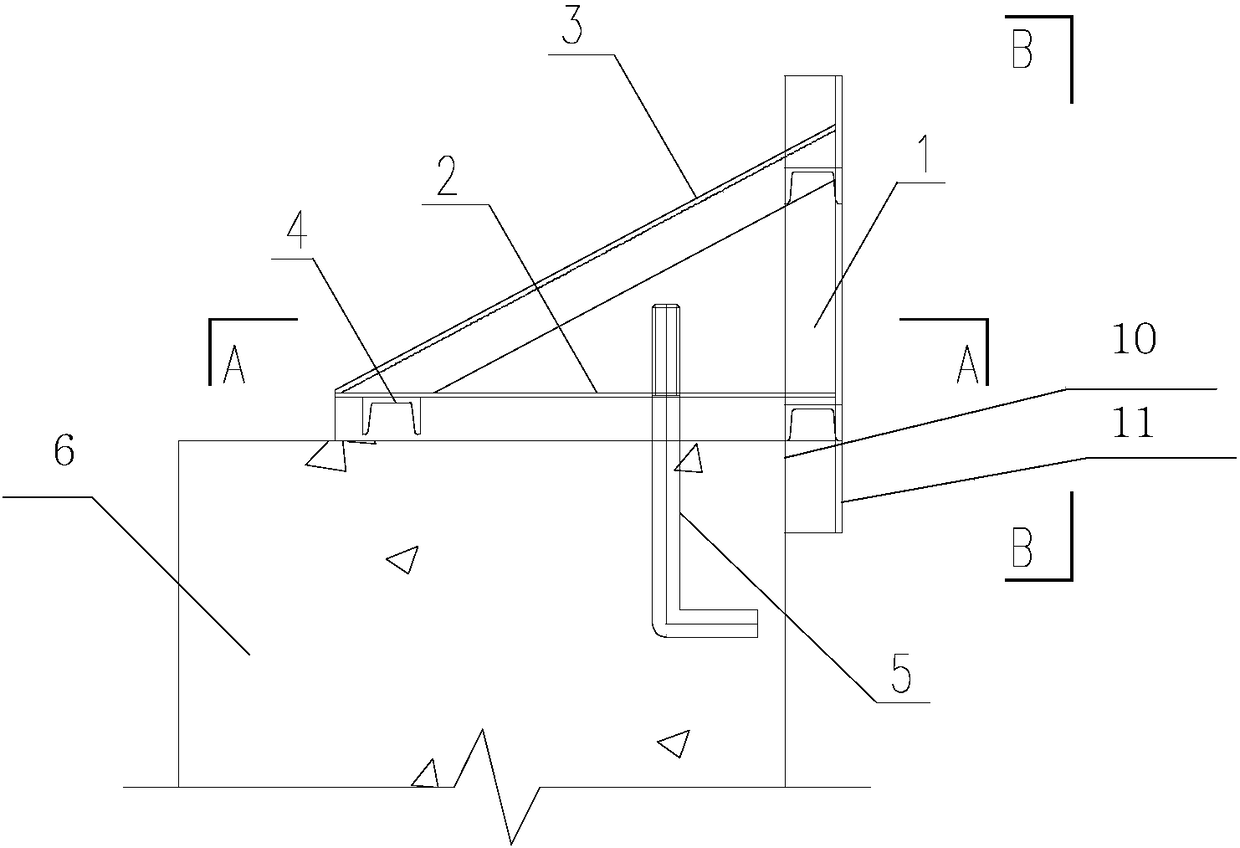

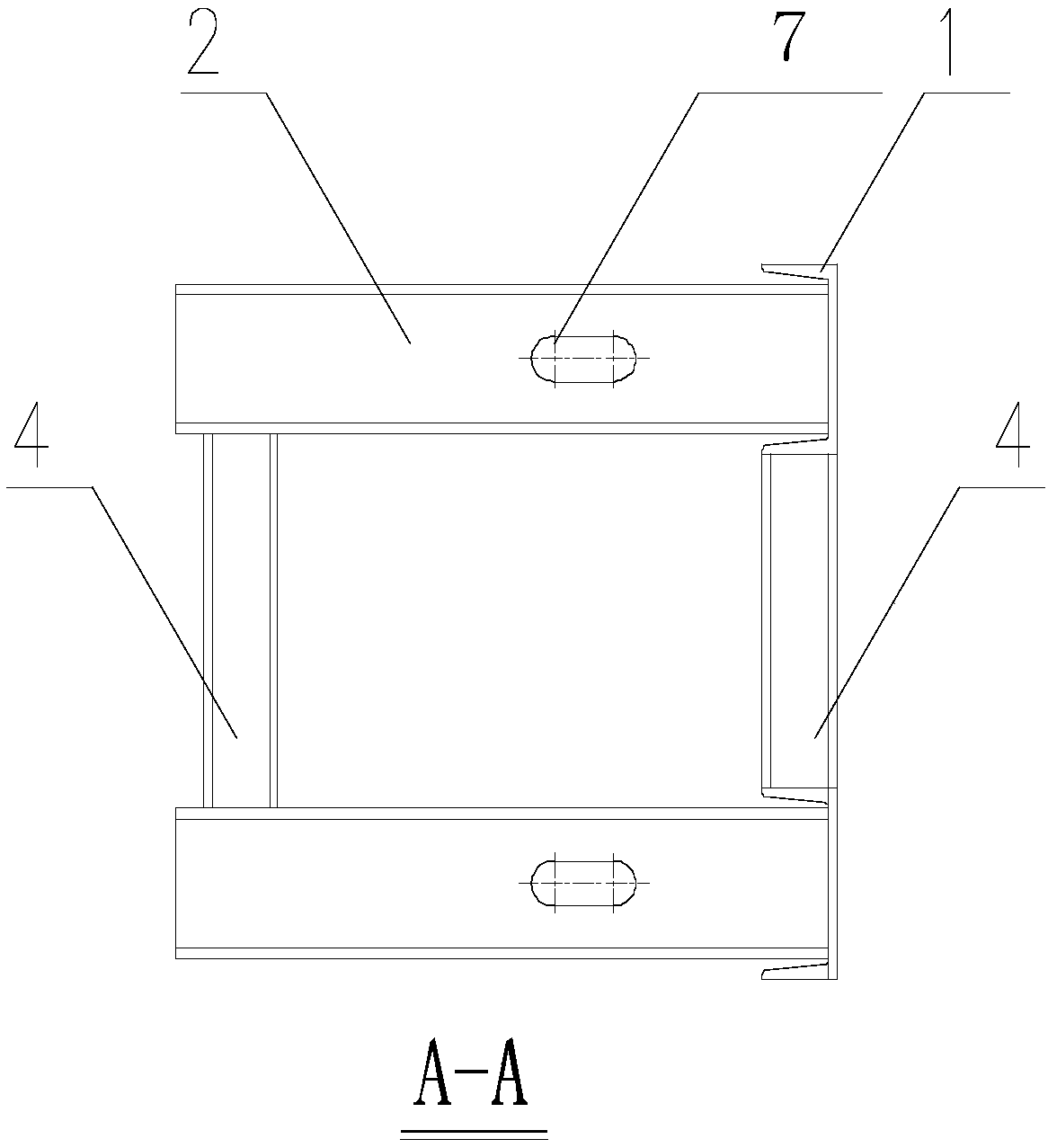

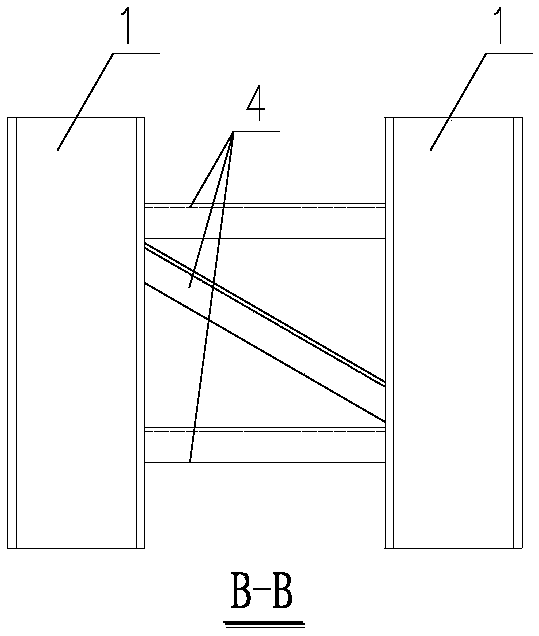

[0050] like Figure 1~6 As shown, the present invention provides a detachable supporting device across the hole, comprising:

[0051] Two pre-embedded screw rods 5 embedded in the structural beam 6 on the hole;

[0052] Two triangular members 100 arranged on the structural beam 6 at preset intervals, each triangular member 100 includes a front upright 1, a bottom cross bar 2, and a diagonal brace 3, and the front upright 1, bottom cross bar 2. Diagonal struts 3 are connected to form a right triangle, the front vertical bar 1 and the bottom cross bar 2 are perpendicular to each other, the bottom cross bar 2 is arranged on the structural beam 6, and the bottom cross bar 2 is connected with the A pre-embedded screw 5 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com