Liquid-controlled liquid flooding coiled tubing drilling tractor

A coiled tubing and tractor technology, applied in the field of coiled tubing drilling tractors with hydraulic control and liquid drive, can solve the problems of poor traction force, no torsion-bearing capacity, and long length of tractors in downhole tractors, so as to ensure circulation space, The effect of strong traction ability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

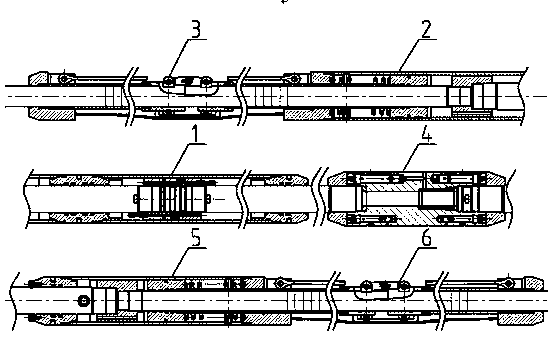

[0049] exist figure 1 Among them, a coiled tubing drilling tractor with hydraulic control and liquid drive includes a propulsion cylinder 1, a rear slip cylinder 2, a rear slip 3, a central valve group 4, a front slip cylinder 5, and a front slip 6.

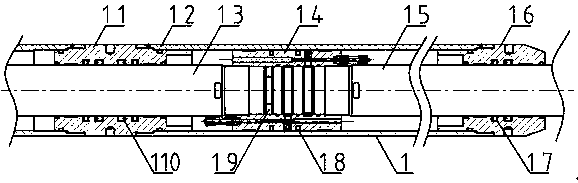

[0050] exist figure 2 Among them, the propulsion cylinder 1 includes a connecting cylinder head 11, a propulsion cylinder barrel 12, a thick center pipe A13, a propulsion cylinder piston 14, a thick center pipe B15, a propulsion cylinder cover 16, a propulsion cylinder head seal guide element 17, a propulsion cylinder piston The seal guide element 18, the push cylinder piston seal 19, and the seal guide element 110 connected to the cylinder head. The connecting cylinder head 11 and the propulsion cylinder head 16 are threadedly connected to both ends of the propulsion cylinder barrel 12, and the thick center pipe A13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com