Extractor hood

The technology of a range hood and an inner cavity is applied in the field of range hoods with sterilization and purification functions, which can solve the problems of external air pollution, poor treatment efficiency, human health impact, etc., and achieve the effects of avoiding the breeding of bacteria and improving the decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

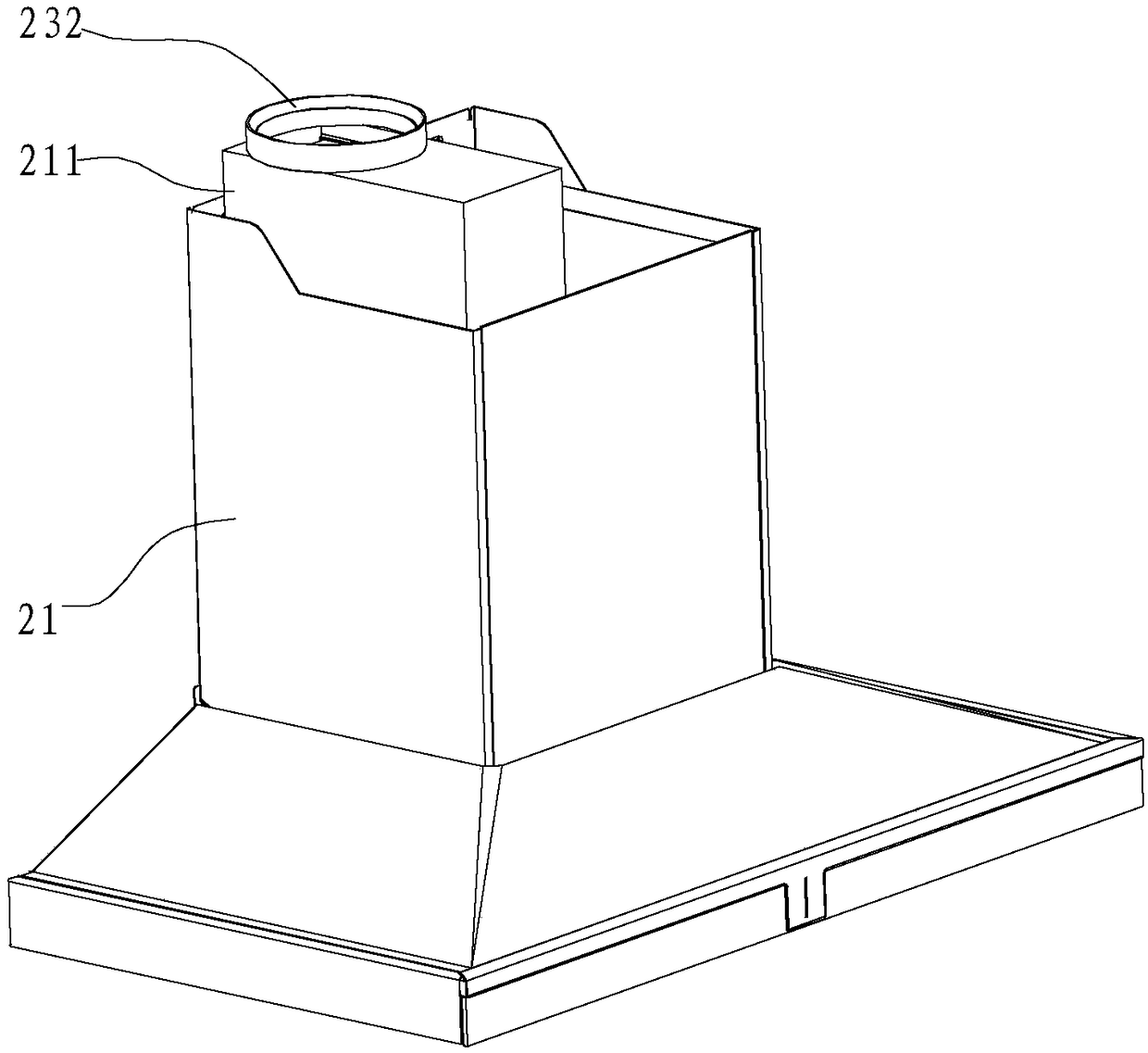

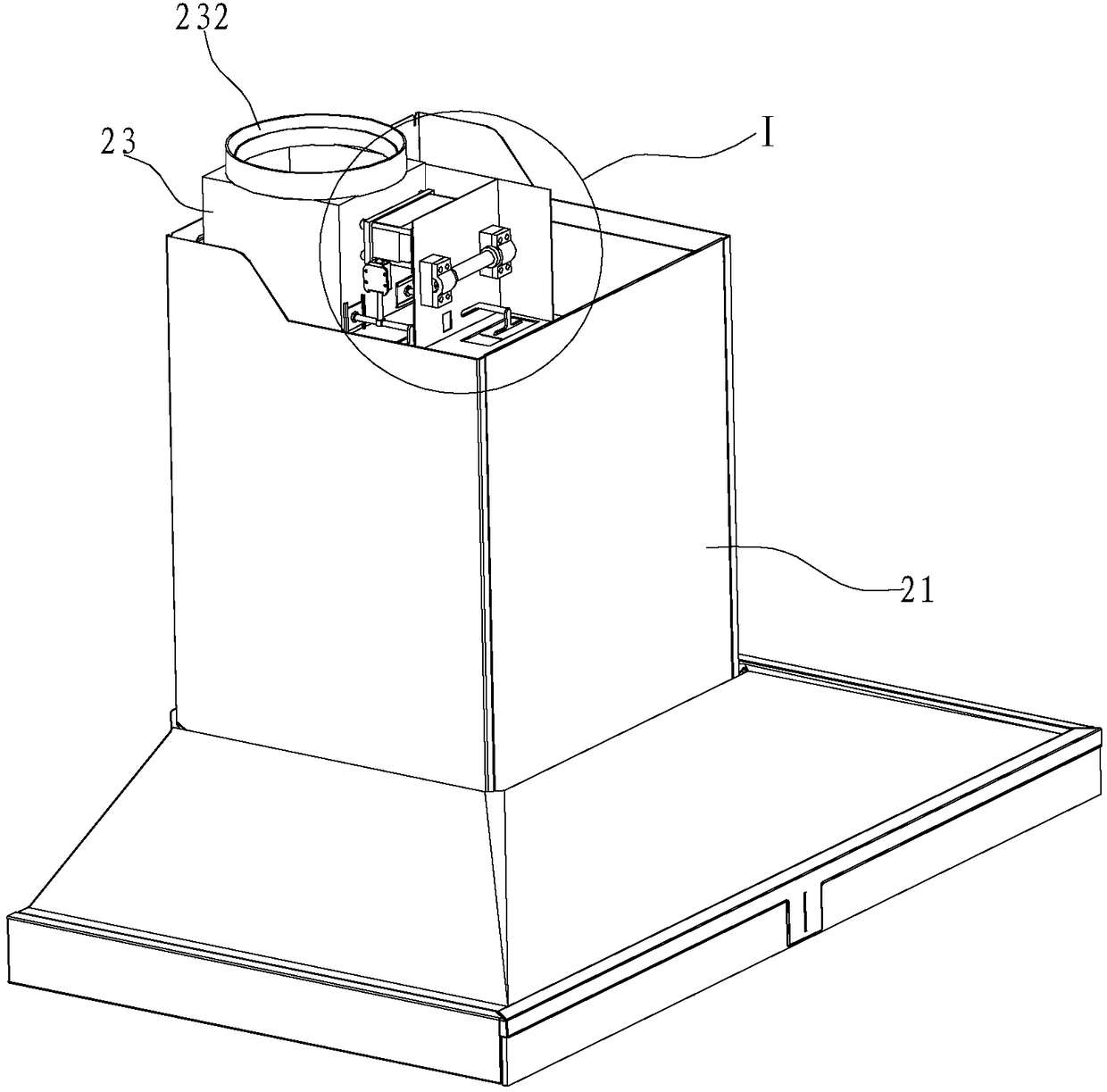

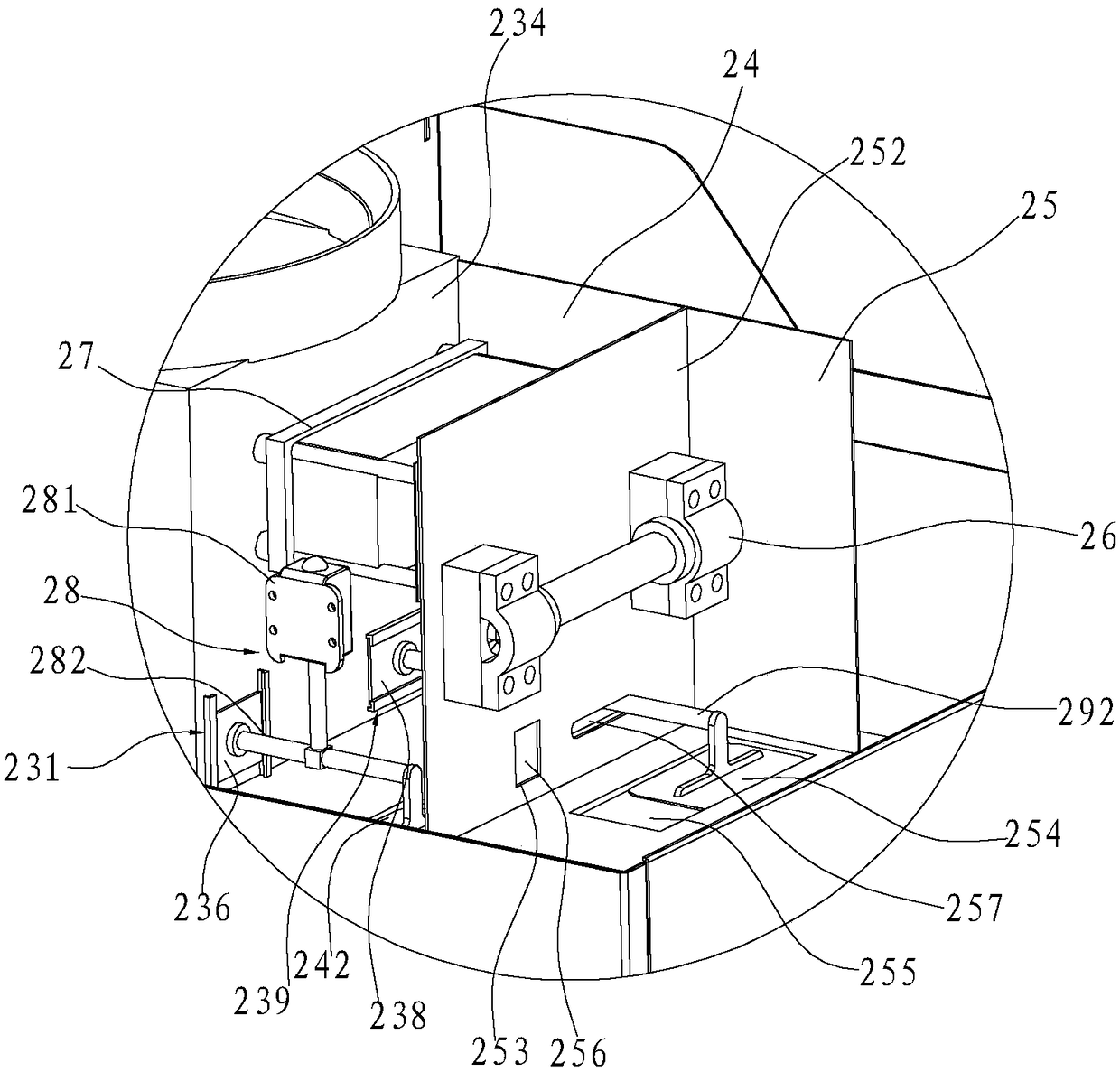

[0035] Such as Figure 1-12As shown, a range hood includes a casing 21 with an inner cavity 210 and an air outlet cover 211, the inner cavity 210 is provided with a fan 22, the above air outlet cover 211 is provided with an air outlet cavity 23, and the outlet The air chamber 23 is located above the inner chamber 210 and communicates with the inner chamber 210 through an air inlet (not shown, which is a conventional structure of a range hood), and the top of the air outlet chamber 23 has an air outlet 232, and the air outlet 232 An air outlet valve plate (not shown, which is a conventional structure of a range hood) capable of opening and closing the air outlet 232 is provided. In this embodiment, the above-mentioned air outlet cover 211 is also provided with a purification chamber 24 and a heating chamber 25. The above-mentioned air outlet chamber 23, purification chamber 24 and heating chamber 25 are all arranged above the inner chamber 210, and the three are arranged side b...

Embodiment 2

[0044] Such as Figures 13 to 14 As shown, different from Embodiment 1, the heating device 26 in this embodiment includes three heating plates 261, and each heating plate 261 is arranged in the heating chamber 25 at intervals along the airflow direction, and the heating plate 261 between adjacent heating plates 261 The gap forms the gas channel 260 so that the gas flow entering the heating chamber 25 can be heated more effectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com