Tea charcoal fire drying room

A technology of drying room and charcoal fire, which is applied in the direction of tea drying, drying, drying machine, etc., can solve the problems of unintuitive drying process, simple equipment, low production efficiency, etc., and achieve standardized operation, mass production, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

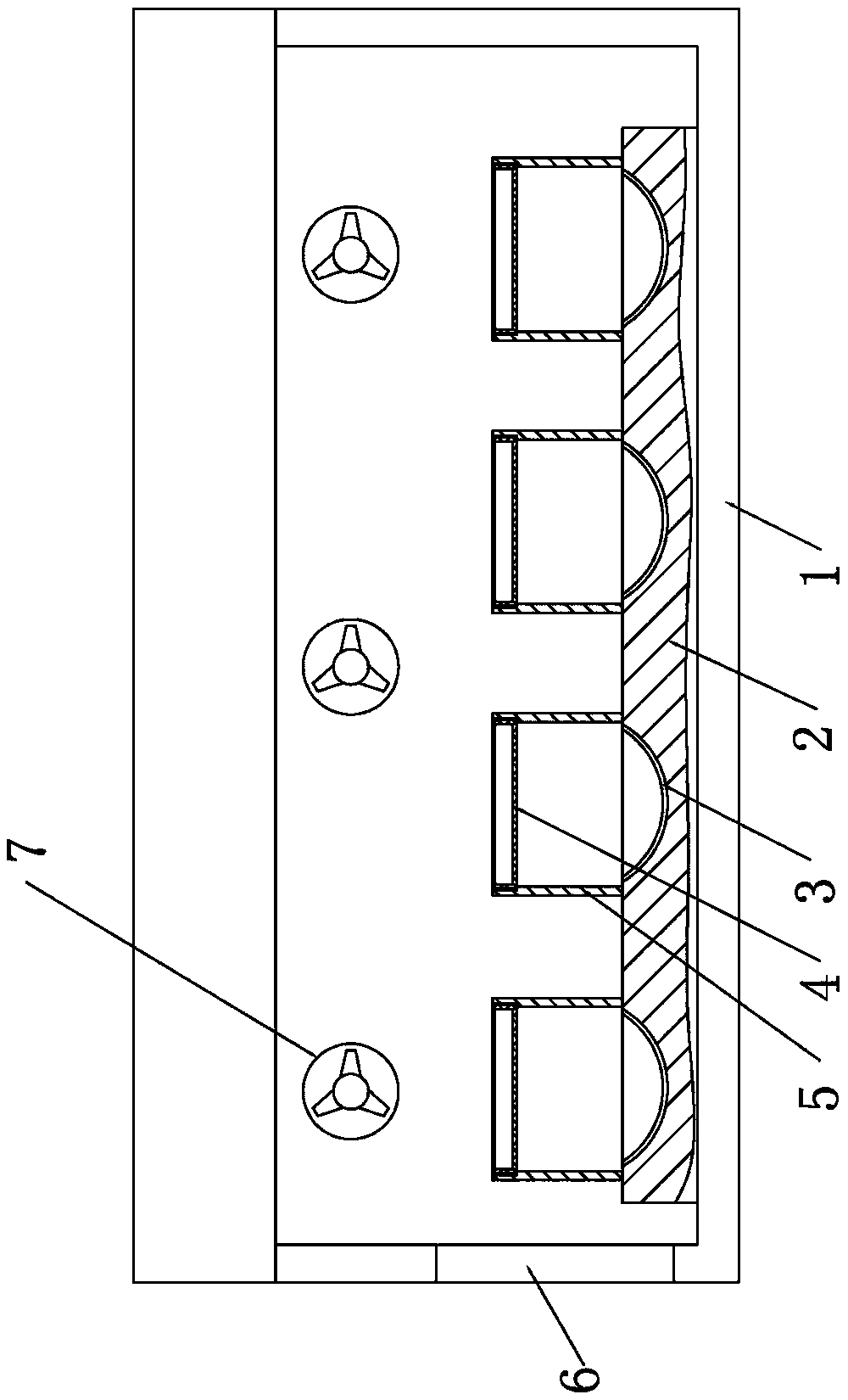

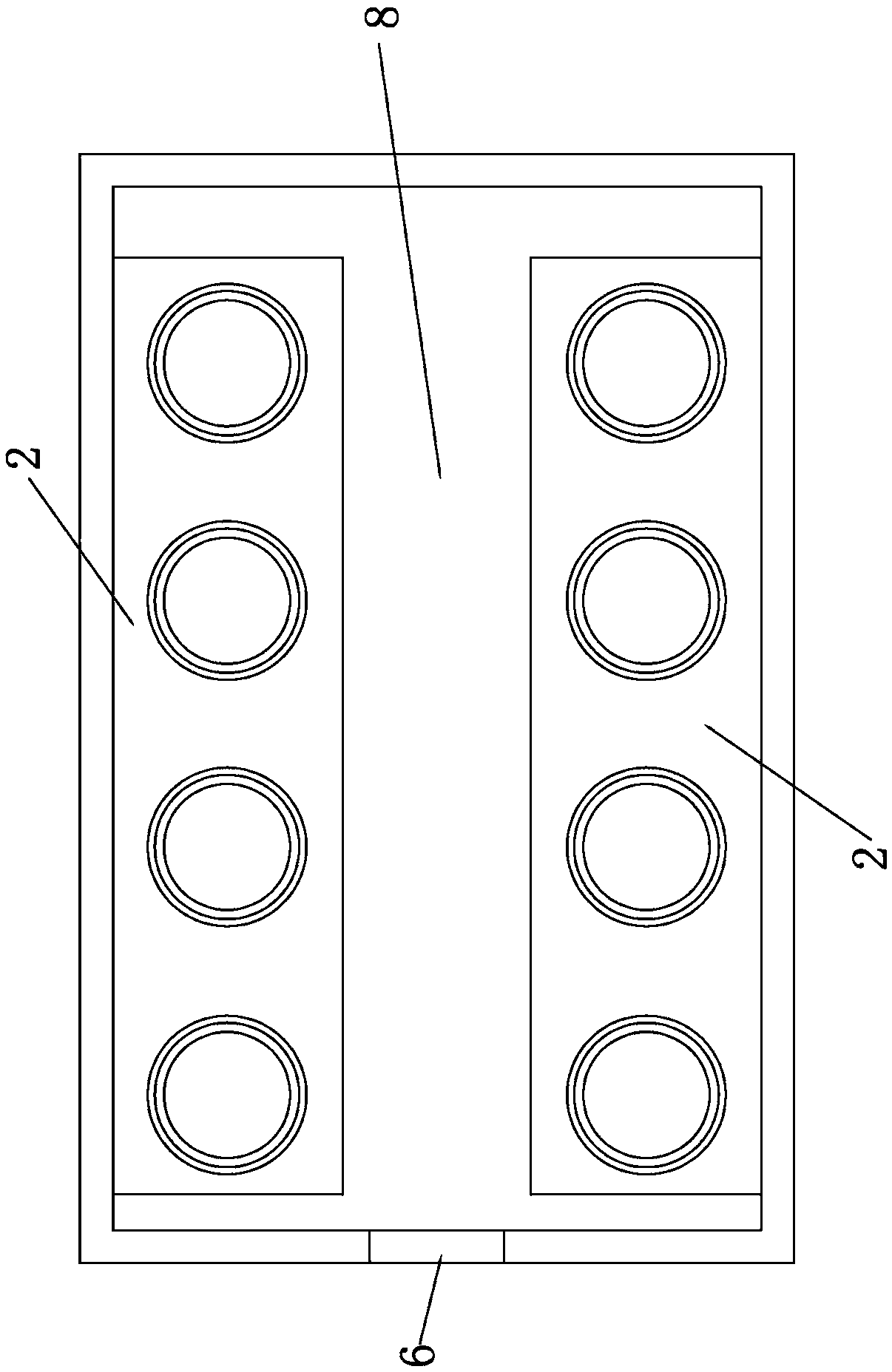

[0010] combine figure 1 , figure 2 As shown, the present invention is further described: the tea charcoal fire drying room includes a room body 1, and what is arranged on both sides of the room body 1 along the length direction is a brazier placement platform 2, and the middle of the room body is an operation channel 8; the brazier placement platform on each side A plurality of braziers 3 are placed along the length direction, and a baking cage 4 is placed above the brazier, and a drying screen 4 is movable on the baking cage 4; the height of the bottom of the baking screen 4 from the brazier 3 is 30-40 cm; charcoal is placed in the brazier; A ventilation fan 7 is provided on the wall of the body 1 to adjust the temperature and humidity of the room body;

[0011] In actual operation, the length of the brazier placement platform 2 and the number of braziers on it are determined according to the length of the room body 1, and no further description is given here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap