Software-defined network type industrial controller

An industrial controller, software-defined technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the lack of seamless integration, the lack of effective and close integration of hardware design and software, and the lack of big data technology. application and other issues to achieve the effect of facilitating networking requirements, realizing data integrity and secure communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

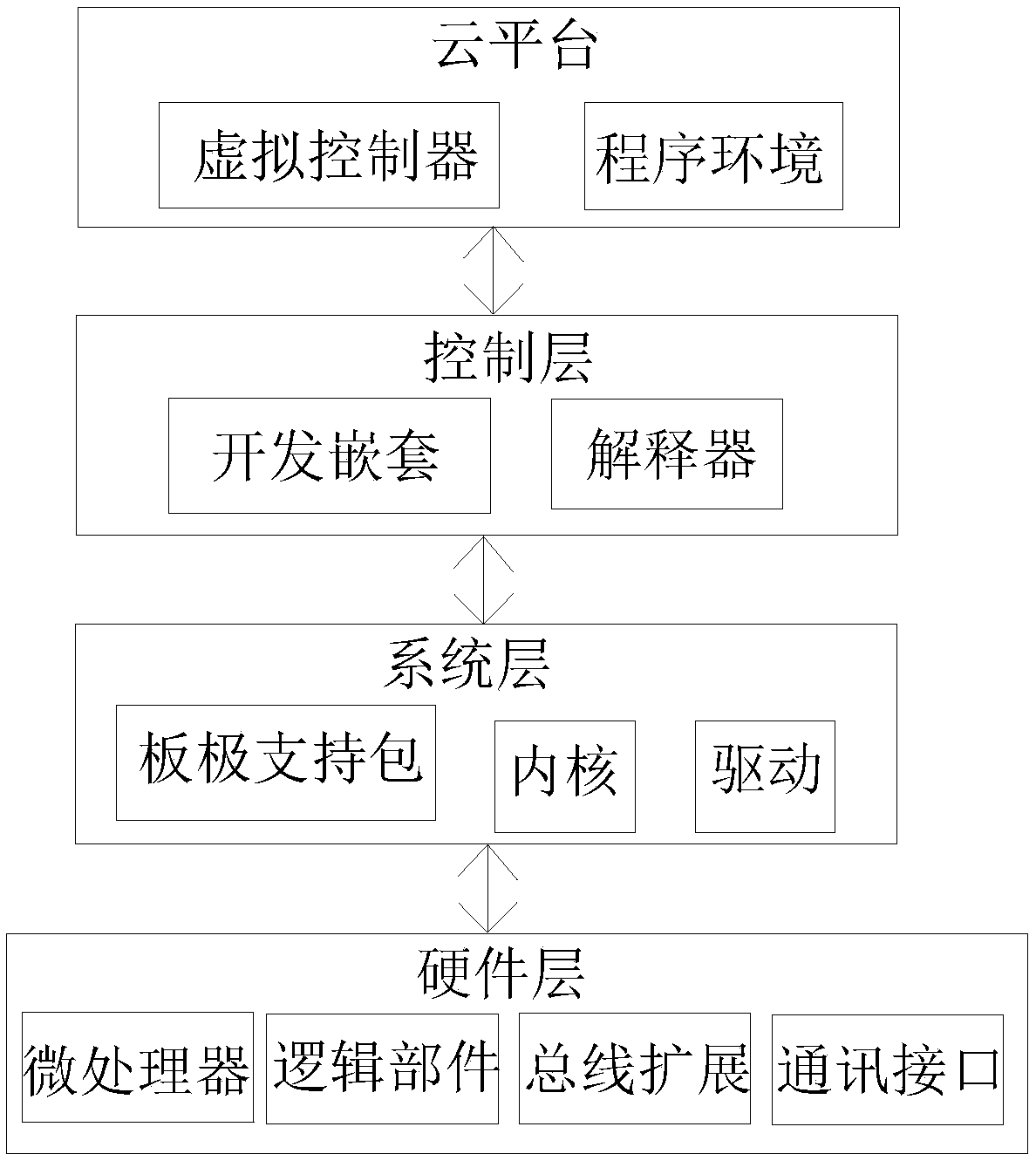

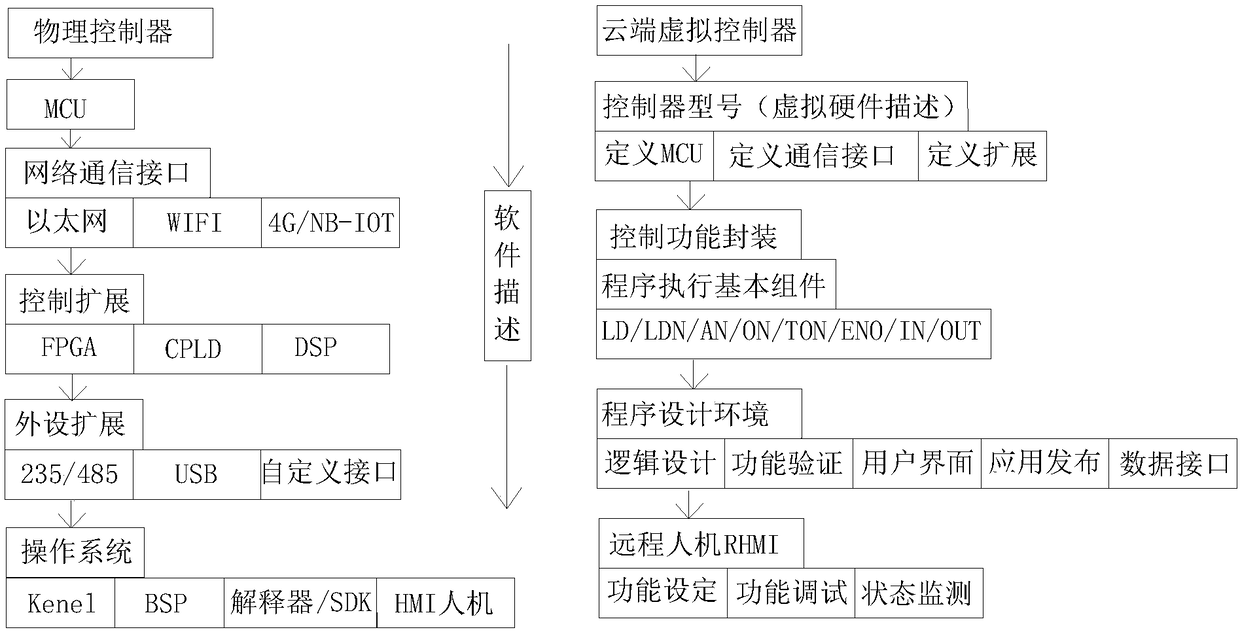

[0031] Applying the network-type industrial controller defined by this software enables the implantation of Internet genes in the design and development stage of industrial equipment, and uses technologies such as cloud and big data to assist the research and development process. After the development of industrial equipment is completed, it has background cloud management, data monitoring, and simulation. , intelligent regulator, etc., allowing users to focus on the optimization of equipment control process, and quickly and easily access the network.

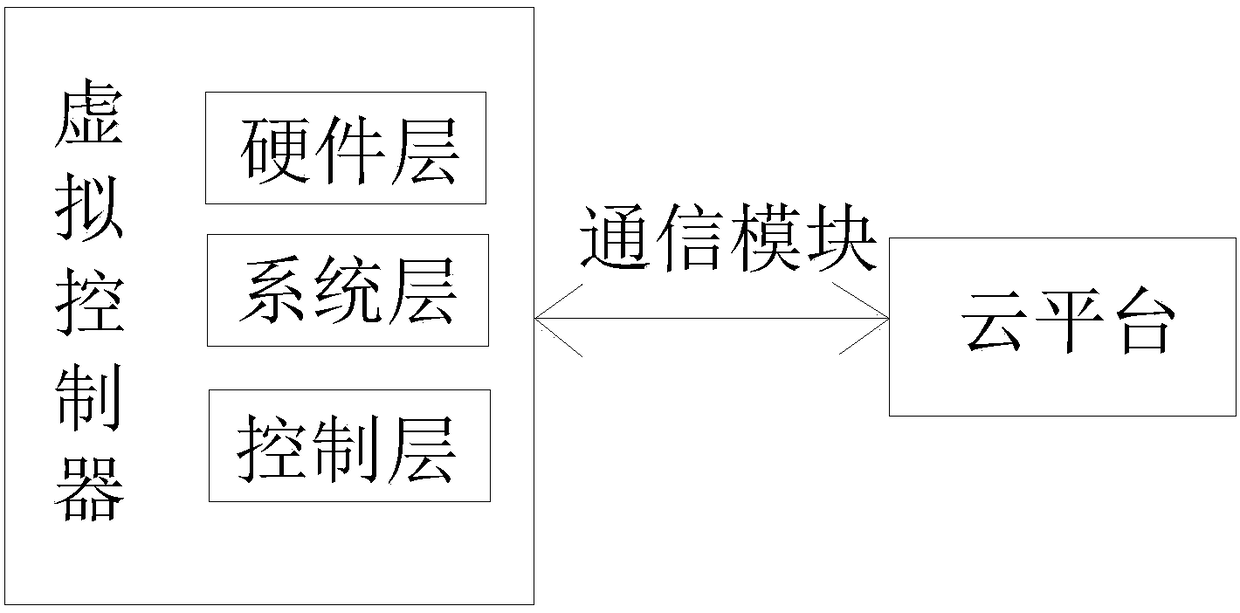

[0032] The technical scheme adopted by the present invention is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com