Magnetostriction device and manufacturing method thereof

A magnetostrictive device technology, applied in the field of magnetostrictive devices and their preparation, to achieve the effects of reducing eddy current loss, broadening the application field, and reducing heat generation

Active Publication Date: 2018-07-03

GRIREM ADVANCED MATERIALS CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, in practical applications, how to apply thin strip-shaped FeGa materials, make full use of its large magnetostrictive properties, and improve its high-frequency magnetostrictive properties and precision actuation stability is still a relatively difficult problem that people face. big technical problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0040] The magnetostrictive device that the present invention relates to mainly adopts the following methods to obtain:

[0041] (1) Flat strip preparation

[0042] The flat strip is prepared by spraying the molten alloy solution onto the rotating roller by induction spraying method and rapidly cooling it.

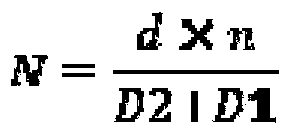

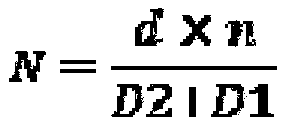

[0043] In this preparation process, the tape composition, thickness d (in μm), and width W (in mm) are as shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

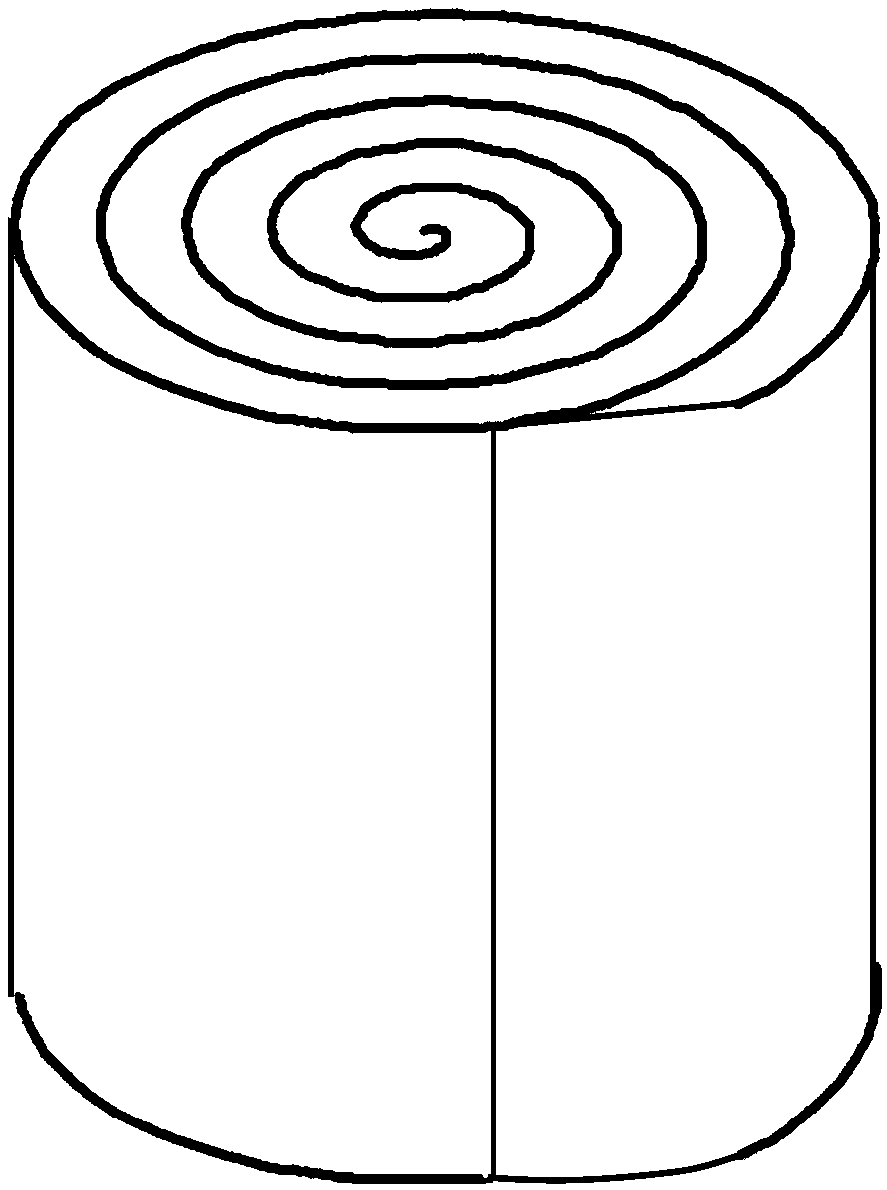

The invention discloses a magnetostriction device, which comprises a magnetostrictive belt core, and is characterized in that the magnetostrictive belt core presents a columnar structure, a spiral loop exists on the relative section, and an induction coil generating a magnetic field is wound in the circumferential direction of the belt core; and the magnetostrictive belt core is formed by windingof a flat belt material, and the lamination coefficient N is 75% to 85%. According to the magnetostriction device, the eddy current loss of the magnetostrictive material at a high frequency can be reduced, the actuation precision of the magnetostrictive material is improved, the material application field is expanded, and the utilization efficiency of the rapidly-quenched magnetostrictive materialcan also be improved.

Description

technical field [0001] The invention relates to a magnetostrictive device and a preparation method thereof, belonging to the field of magnetic material devices. Background technique [0002] Fe-Ga alloy is a new type of magnetostrictive material. Compared with traditional Terfenol-D, its biggest feature is that it has a lower saturation magnetic field and higher mechanical strength, and the saturation field is as low as 8-17kA / m , about 1 / 10 of Terfenol-D, high magnetic field sensitivity. In some applications, there is no need to use complex prestressed structures, and the device structure design is relatively simple. Fe-Ga alloy is a metal solid solution with high strength, low brittleness, high tensile strength (500MPa) and ductility, especially suitable for harsh conditions with strong vibration, impact, heavy load and strong corrosion. In addition, the alloy has high magnetic permeability, high Curie temperature, good temperature characteristics, and can be used in a w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L41/12H01L41/20H01L41/47

CPCH10N35/00H10N35/85H10N35/01

Inventor 罗阳谢佳君彭海军于敦波闫文龙权宁涛杨远飞豆亚坤

Owner GRIREM ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com