Method for increasing cutting fixed length yield of casting machine

A qualified rate, fixed-length technology, applied in the field of metallurgical control, can solve the problems of increased maintenance costs, poor encoder coaxiality, periodic wear of measuring rollers, etc. no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

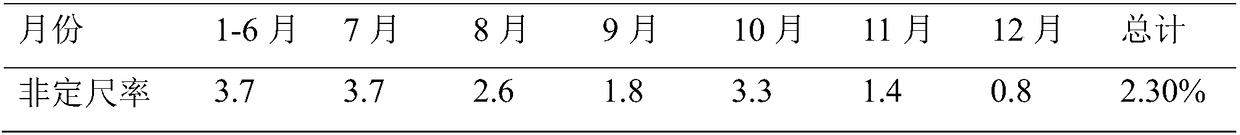

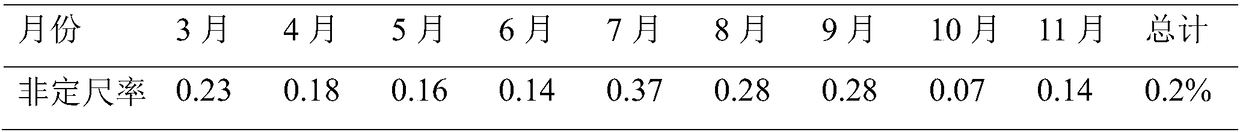

[0028] The method for improving the qualified rate of casting machine cutting to length includes the following steps;

[0029] Create a data block, write the mode, casting speed, casting length and other information into the data block, and unify the calculation unit: the data in the casting flow PLC, the casting speed calculated by the encoder of the tension leveling machine, the hot billet casting tracking length and the casting The mode is sent to the PLC of the cutting machine through Ethernet communication, and the communication rate is increased at the same time to ensure the real-time performance of data update. It is set in the program at the same time. Once the encoder data detection failure is detected, it will be automatically switched to ensure continuous production. ;The communication rate is set to 300ms in the data communication program between the casting strand and the cutting machine to ensure the efficiency of data transmission and to ensure the stability of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com