Ultrasonic welding device

An ultrasonic welding and welding head technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that materials can only be supplied from the left and right directions of the machine head, the scope of application is small, and the size cannot be too large. The effect of reducing design cost, wide application range and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

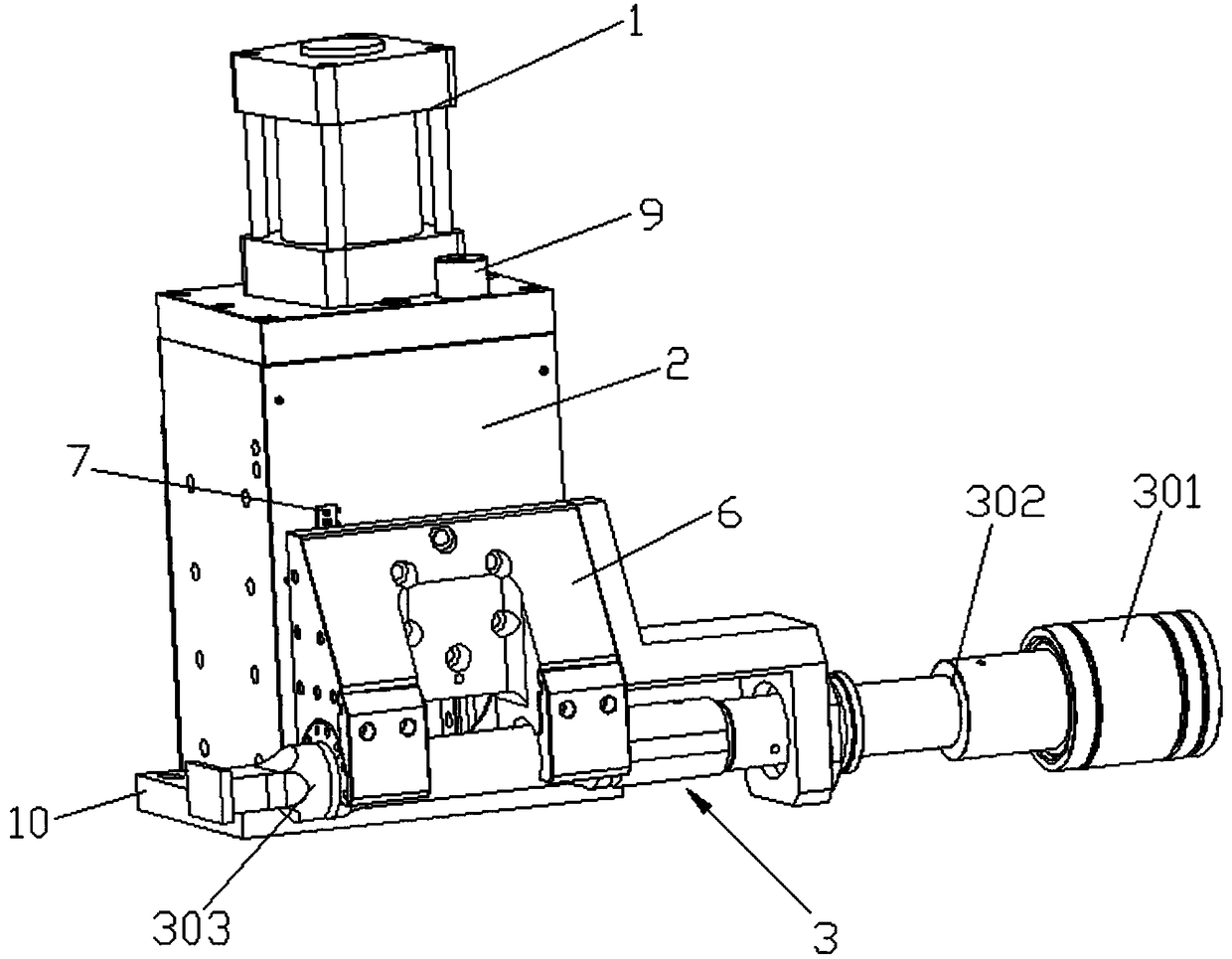

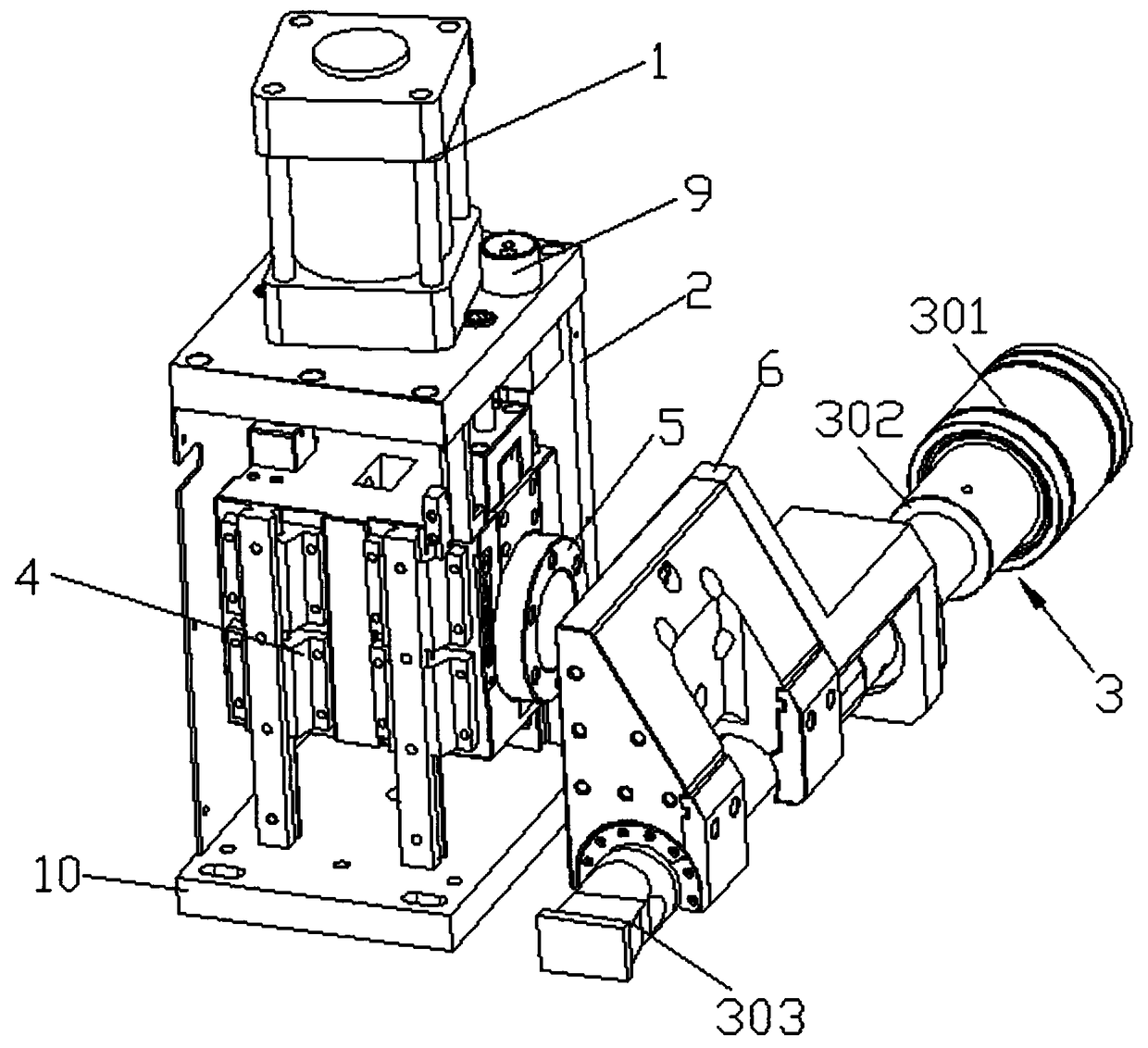

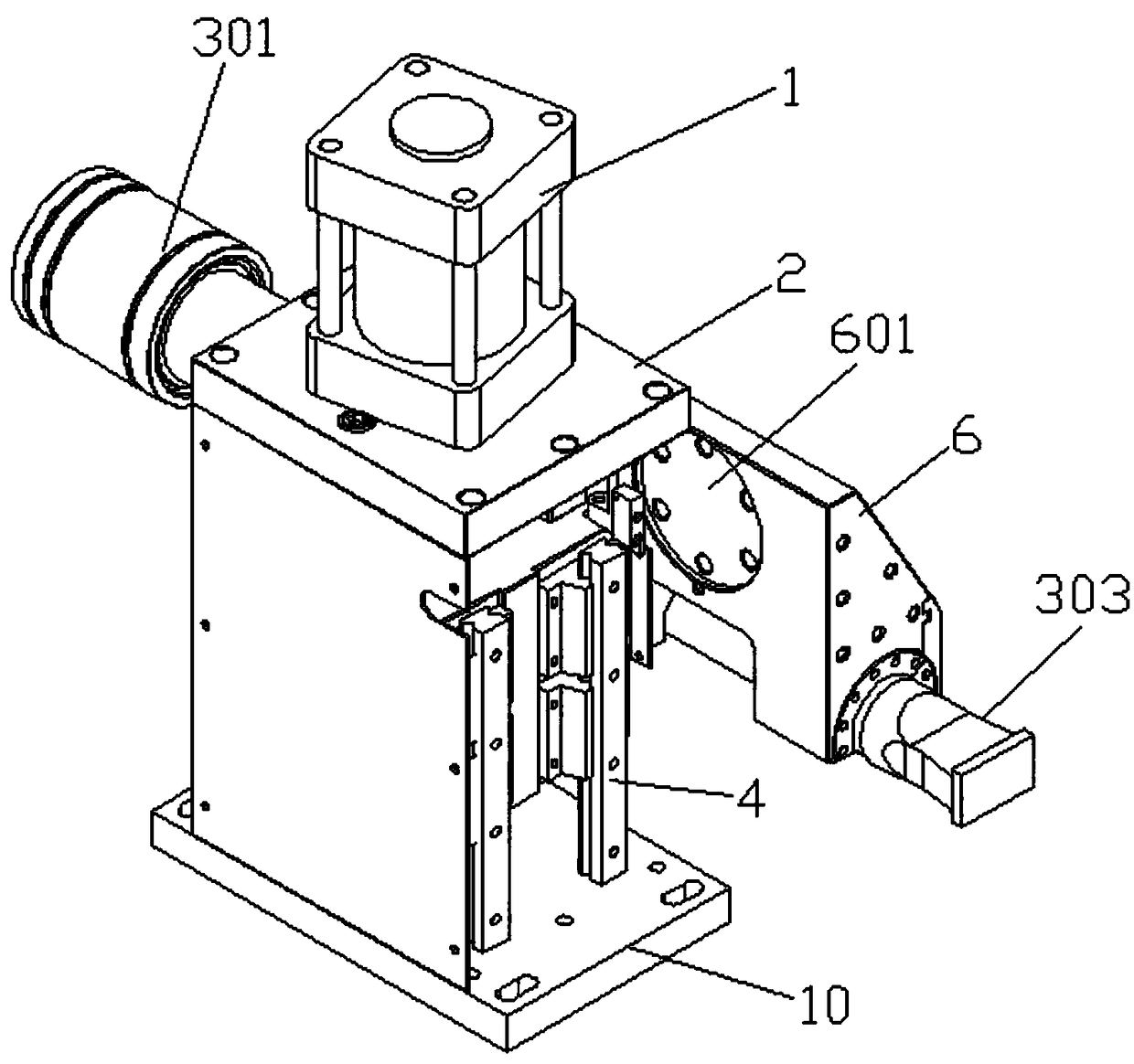

[0022] Such as Figure 1~4 As shown, the ultrasonic welding device of the present invention mainly includes a driving mechanism 1 , a machine head 2 and a transducer assembly 3 , and the machine head 2 can be installed on a base 10 . The machine head 2 is provided with a bracket 4, and the bracket 4 is connected with the power output end of the driving mechanism 1, that is, the driving mechanism 1 drives the bracket 4 to move up and down. The transducer assembly 3 is arranged in front of the machine head 2 and is fixedly connected to the bracket 4. The fixed connection method is as follows: a sleeve 5 is arranged on the bracket 4, and the transducer assembly 3 is supported by a mounting frame 6, and the mounting frame 6 A nesting portion 601 matching the sleeve 5 is provided on the top, so that the sleeve 5 is nested and fixed with the nesting portion 601 by screws.

[0023] The transducer assembly 3 includes a transducer 301, a horn 302 and a welding head 303 connected in se...

Embodiment 2

[0027] Such as Figure 5 As shown, the only difference from Embodiment 1 is that the welding head 303 with the welding position on the right side is selected, and the welding head 303, the horn 302 and the transducer 301 are installed in sequence from right to left, and the incoming materials can be transferred from the machine The right side of head 2 is used for vertical or horizontal incoming material production welding. Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] Such as Figure 6 As shown, the only difference from Embodiment 1 is that the welding head 303 with the welding position in the middle is selected, and the welding head 303, the horn 302 and the transducer 301 are installed in sequence from left to right, and the incoming material can be obtained from the machine head. 2. Bottom longitudinal or horizontal incoming material production welding. Other structures are the same as those in Embodiment 1, and will not be repeated here.

[0030] Working principle of the present invention:

[0031] The ultrasonic welding device of the present invention is used in conjunction with the lower ultrasonic welding seat (lower mold or lower sonotrode or lower welding head) and an ultrasonic generator, and the ultrasonic generator is electrically connected to the transducer 301 . The transducer 301 converts the high-frequency electric energy emitted by the ultrasonic generator into mechanical motion of the same frequency. The horn 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com