Closed heat-dissipating charging pile

A charging pile and heat-dissipating technology, which is applied in the field of closed heat-dissipating charging piles, can solve the problems of clogging dust-proof cotton, excessive heat generation of electrical components, and rising temperature of charging piles, so as to prevent rain and dust from entering, improve cooling effect, The effect of improving the protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

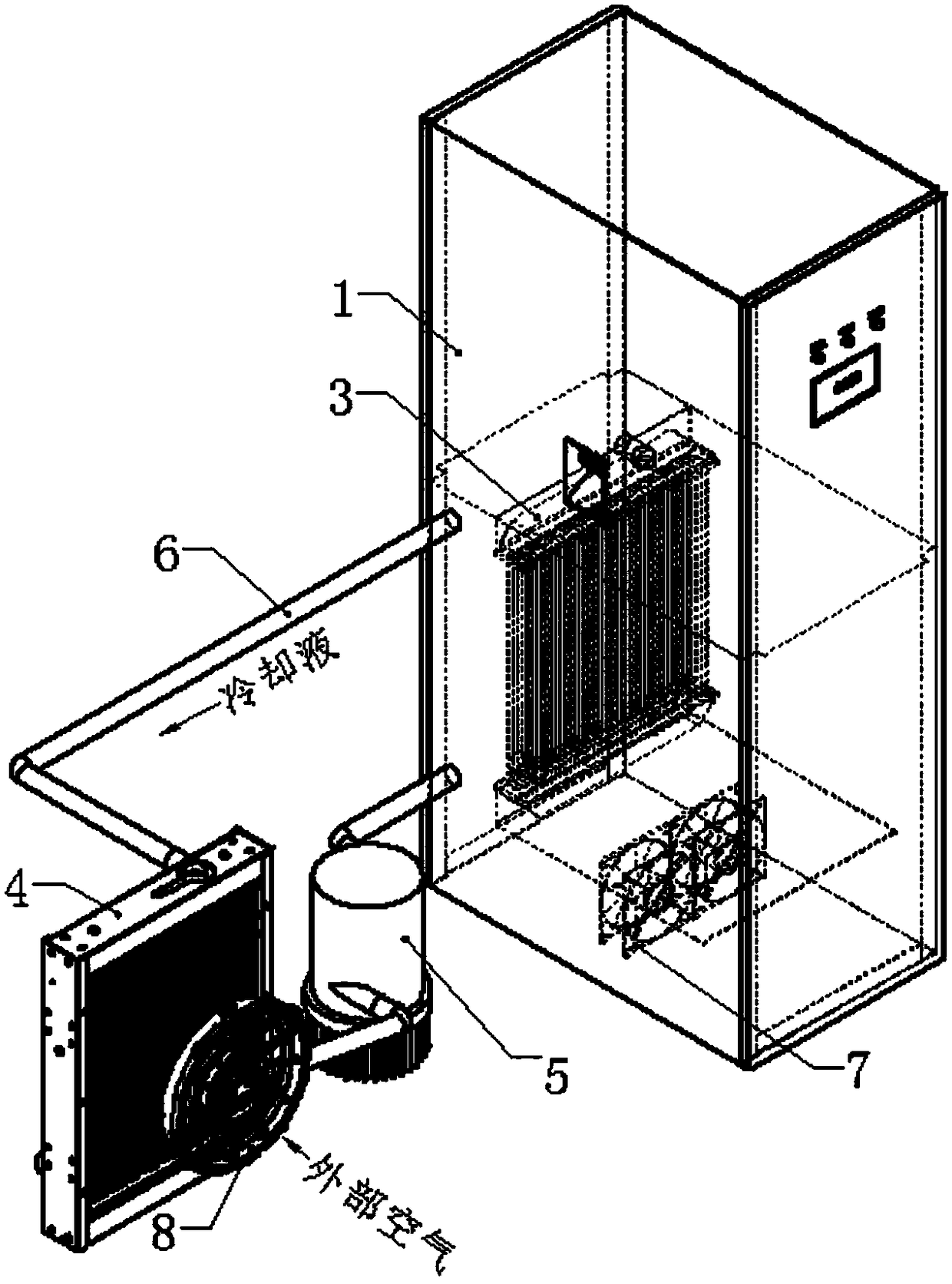

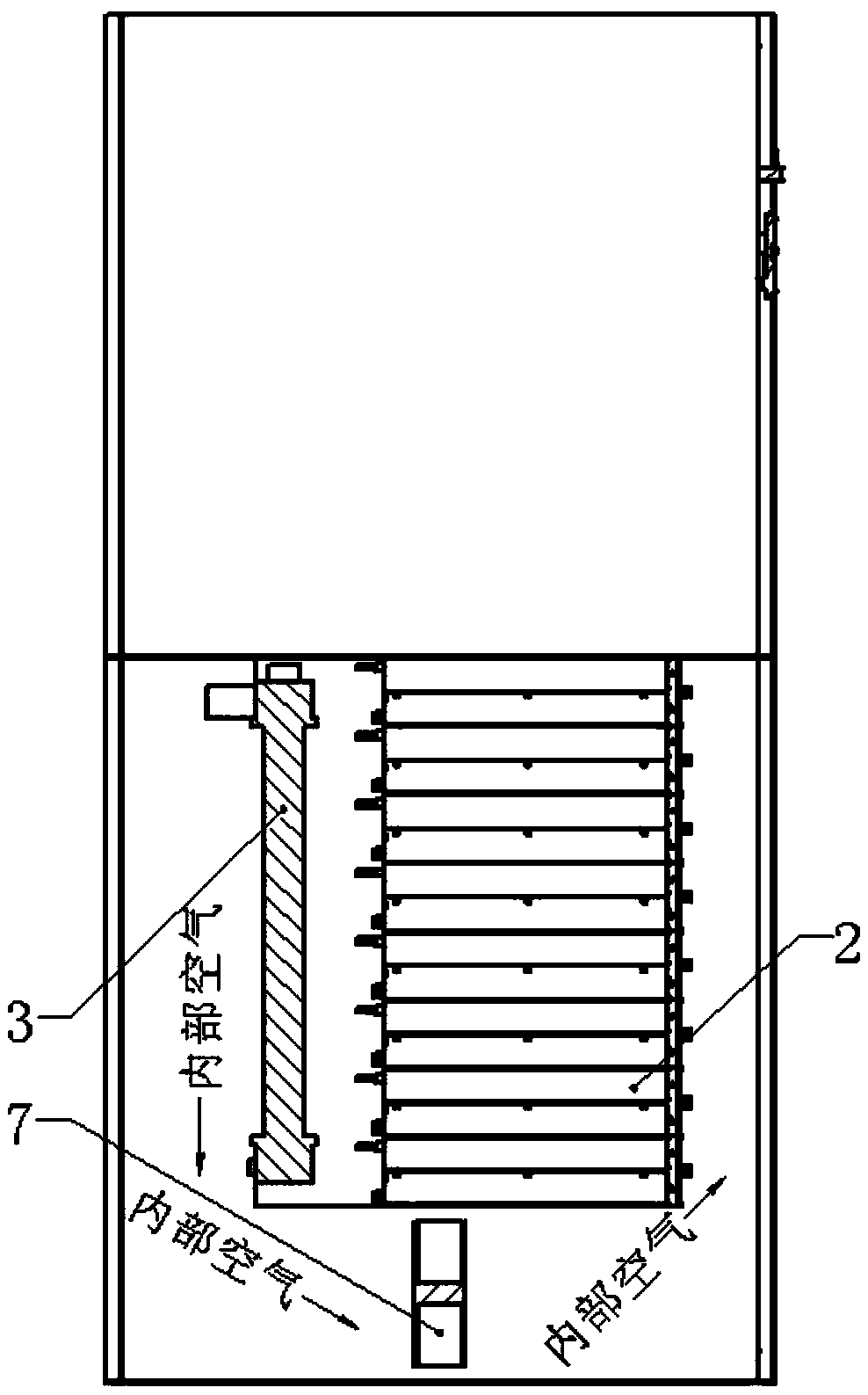

[0011] Such as figure 1 and figure 2 , a closed heat dissipation charging pile of the present invention, comprising a power cabinet 1, a charging module 2, an internal radiator 3, an external radiator 4, a water pump 5, a water pipe 6, an internal fan 7 and an external fan 8, a charging module 2, an internal heat dissipation The radiator 3 and the internal fan 7 are arranged in the inner cavity of the power cabinet 1, the external radiator 4, the water pump 5 and the external fan 8 are placed outside the power cabinet 1, and the external fan 8 is placed on the side of the external radiator 4. The internal radiator 3 and the external radiator 4 are connected through a water pipe 6, and the external radiator 4 and the water pump 5 are connected through a water pipe 6. The internal radiator 3, the external radiator 4, the water pump 5 and the water pipe 6 is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com