Rail-mounted robot movement mechanism

A mobile mechanism and robot technology, which is applied to the device for lateral relative movement between the underframe and the bogie, preventing railway derailment, transporting passenger cars, etc., to achieve the effects of high speed, preventing overturning and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

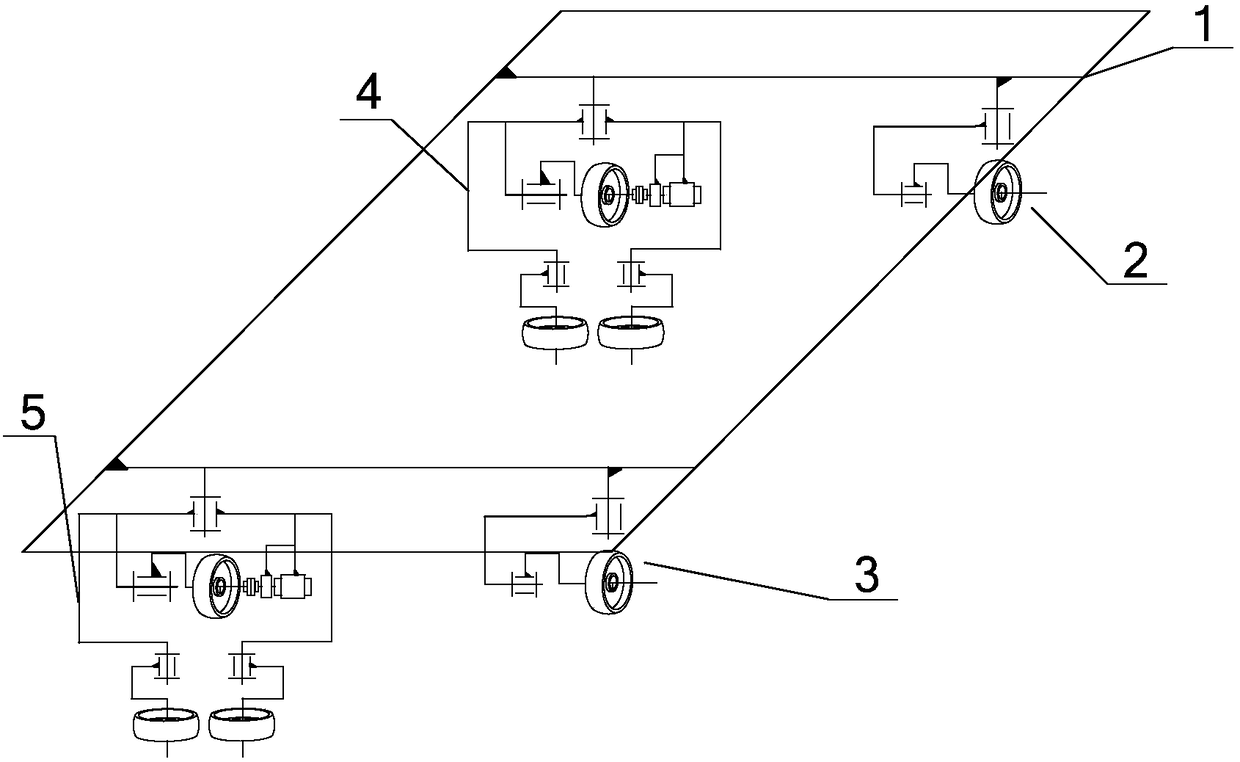

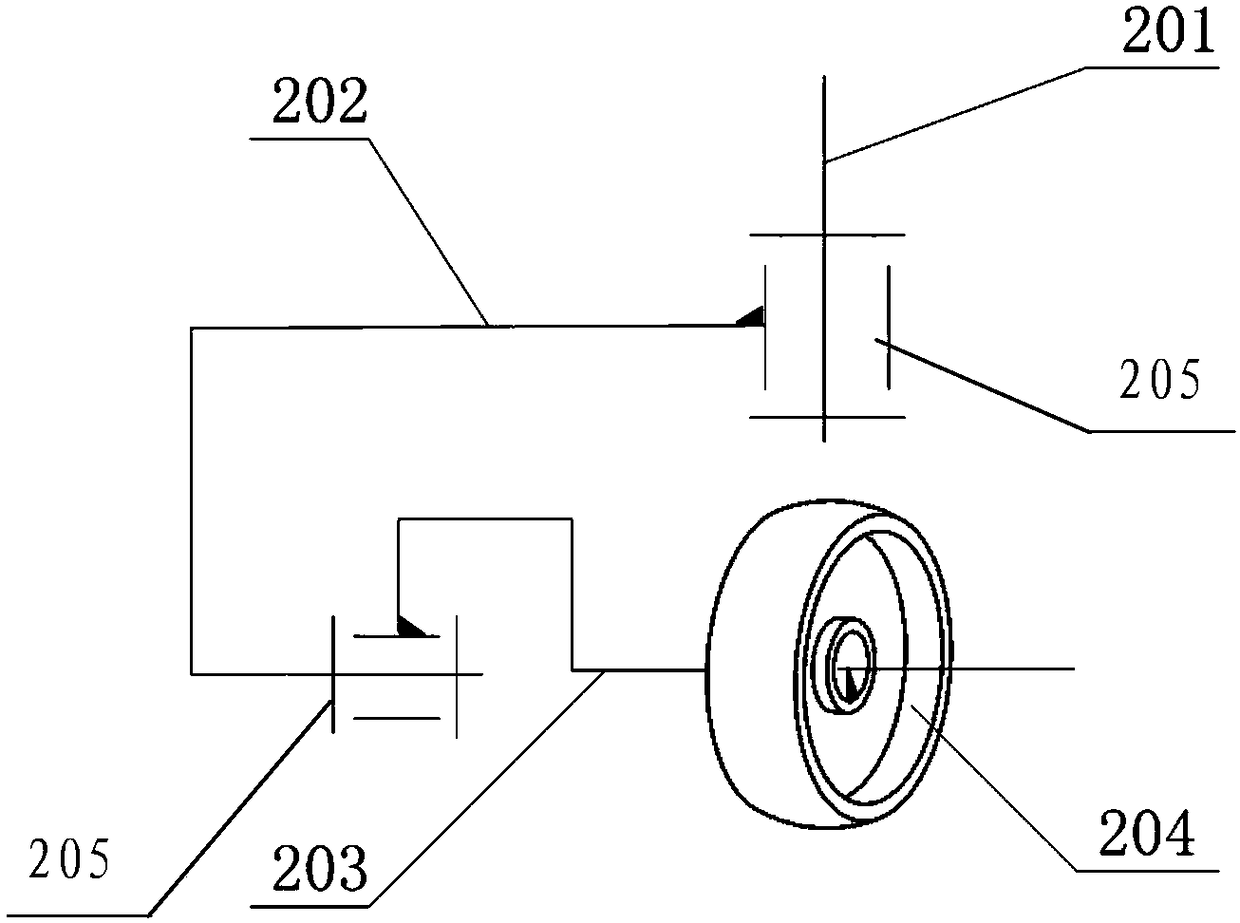

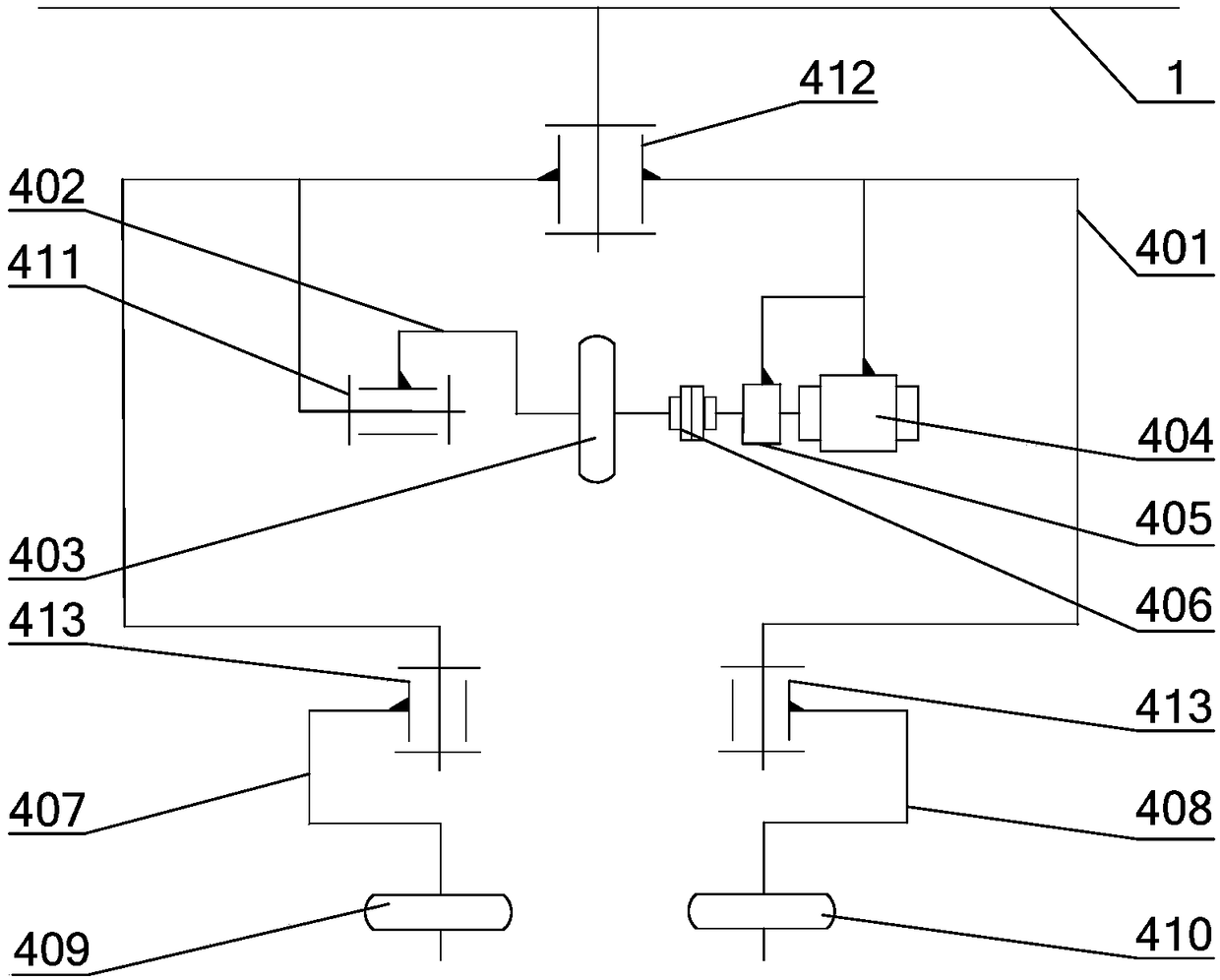

[0026] Such as figure 1 Shown, the present invention comprises mobile car body chassis 1, front universal wheel 2, rear universal wheel 3, front bogie 4 and rear bogie 5, wherein front universal wheel 2 and rear universal wheel 3 are respectively connected with mobile car The body chassis 1 is fixedly connected, and the front bogie 4 and the rear bogie 5 are respectively connected with the mobile body chassis 1 through rotating joints. The front bogie 4 and the rear bogie 5 are straddled on the track 7 to provide supporting force and ensure that the moving car body does not break away from the track. The front universal wheel 2 and the rear universal wheel 3 are used to provide supporting force and increase the stability of the mobile vehicle body.

[0027] The mobile car body chassis 1 is square, and the front and rear universal wheels 2, 3 and the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com