Micro-modeling material for fair-faced concrete

A technology of fair-faced concrete and modeling materials, applied in the field of building materials, which can solve the problems of expensive imported materials, reflective appearance, obvious repair marks, and cure the symptoms, not the root cause, etc., and achieve the effects of good adhesion interface, restoration of smoothness, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

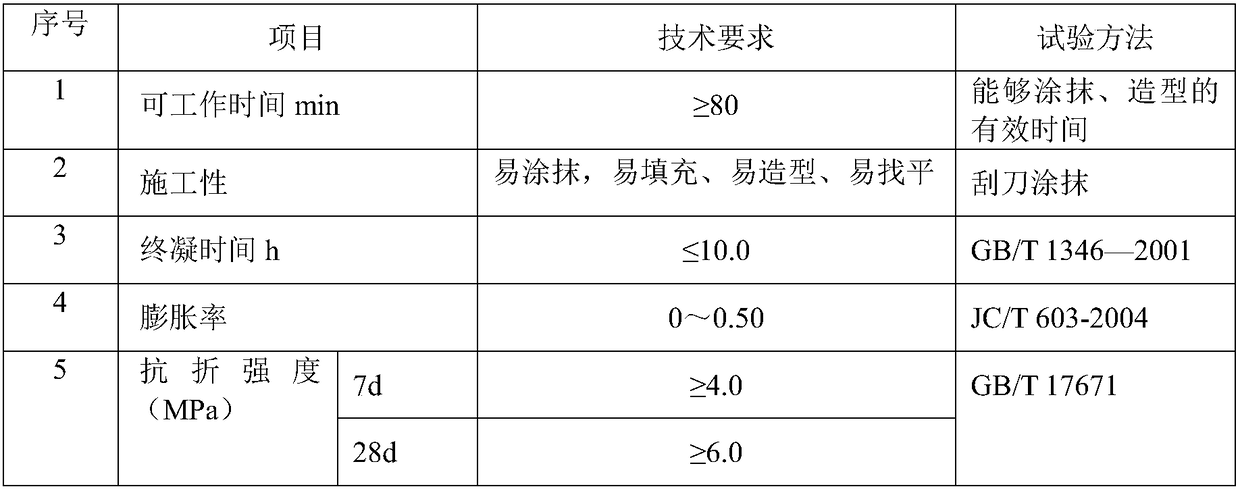

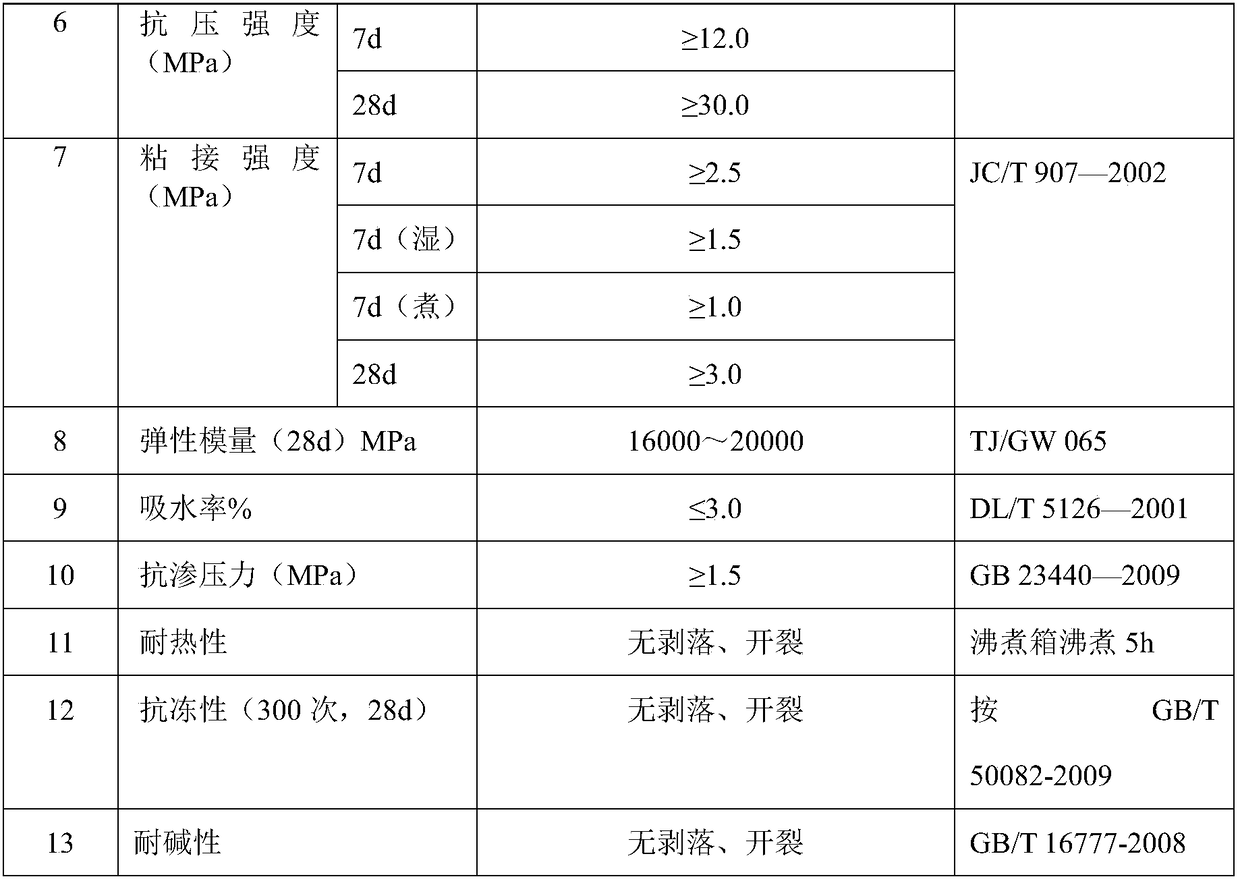

Image

Examples

Embodiment 1

[0032] A clear-faced concrete microscopic modeling material, including powder and liquid, wherein the liquid accounts for 10% of the weight of the powder; the powder is composed of the following components by mass: 320 kg of ordinary Portland cement with a strength grade of P O42.5R , 20 kg of 42.5-grade fast-hardening sulfoaluminate cement, 20 kg of superfine silica fume of 500 mesh, 30 kg of talcum powder of 325 mesh, 75 kg of quartz machine-made sand of 40-80 mesh, 495 kg of river sand with a fineness of 1.8mm, poly 2.1 kg of carboxylic acid powder water reducer, 0.2 kg of plastic calcium sulfoaluminate expansion agent, 0.3 kg of organosilicon defoamer, 0.2 kg of hydroxypropyl methylcellulose thixotropic agent; the liquid is composed of the following components by weight Sub-components: modified carboxylated styrene-butadiene latex 10 kg, water 90 kg.

[0033] When in use, the above-mentioned raw materials are stirred and mixed evenly to repair the appearance defects (pimpl...

Embodiment 2

[0040] A kind of clear-water concrete microscopic molding material, including powder and liquid, wherein the liquid accounts for 7% of the weight of the powder; the powder is composed of the following components by mass: 320 kg of ordinary Portland cement with a strength grade of P O42.5R , 30 kg of 42.5-grade fast-hardening sulfoaluminate cement, 20 kg of superfine silica fume of 500 mesh, 30 kg of talcum powder of 325 mesh, 55 kg of quartz machine-made sand of 40-80 mesh, 495 kg of river sand with a fineness of 1.8mm, poly 2.1 kg of carboxylic acid powder water reducer, 0.2 kg of plastic calcium sulfoaluminate expansion agent, 0.3 kg of silicone defoamer, 0.25 kg of hydroxypropyl methylcellulose thixotropic agent; the liquid preparation consists of the following components by weight Sub-components: modified carboxylated styrene-butadiene latex 12 kg, water 88 kg.

[0041] When in use, the above-mentioned raw materials are stirred and mixed evenly to repair the appearance def...

Embodiment 3

[0044] A kind of clear-water concrete microscopic molding material, including powder and liquid, wherein the liquid accounts for 8% of the weight of the powder; the powder is composed of the following components by mass: 320 kg of ordinary Portland cement with a strength grade of P O42.5R , 15 kg of 42.5-grade fast-hardening sulfoaluminate cement, 20 kg of superfine silica fume of 500 mesh, 30 kg of talcum powder of 325 mesh, 55 kg of quartz machine-made sand of 40-80 mesh, 465 kg of river sand with a fineness of 1.8mm, poly 2.1 kg of carboxylic acid powder water reducer, 0.2 kg of plastic calcium sulfoaluminate expansion agent, 0.3 kg of silicone defoamer, 0.25 kg of hydroxypropyl methylcellulose thixotropic agent; the liquid preparation consists of the following components by weight Sub-components: modified carboxylated styrene-butadiene latex 10 kg, water 90 kg.

[0045] When in use, the above-mentioned raw materials are stirred and mixed evenly to repair the appearance def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com