Heavy oil viscosity breaking method based on super-critical benzene and application thereof

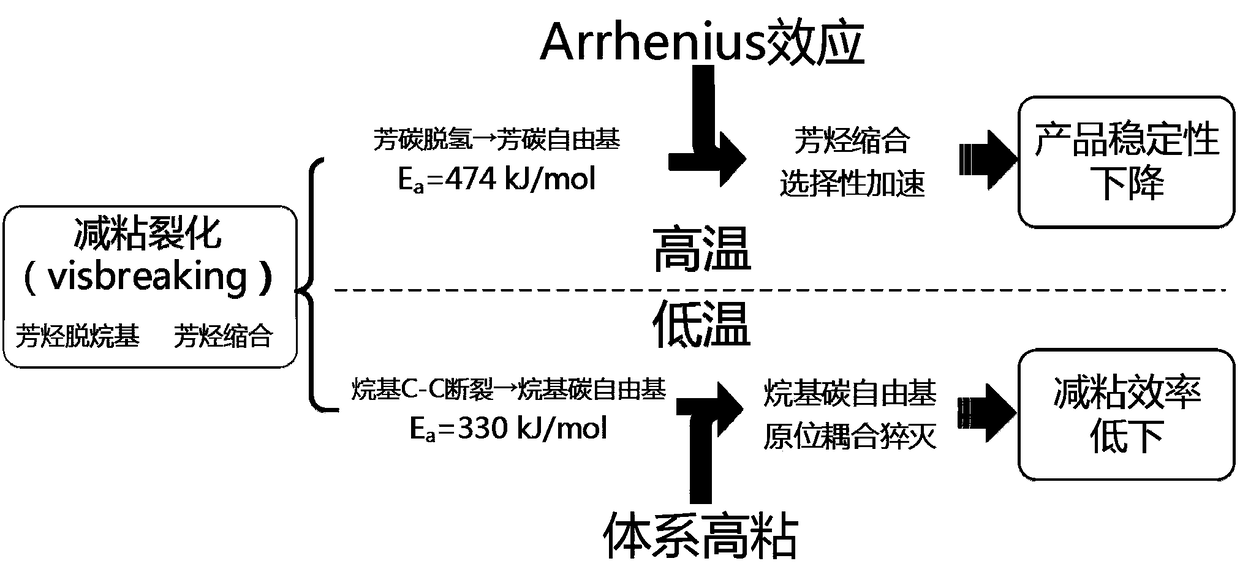

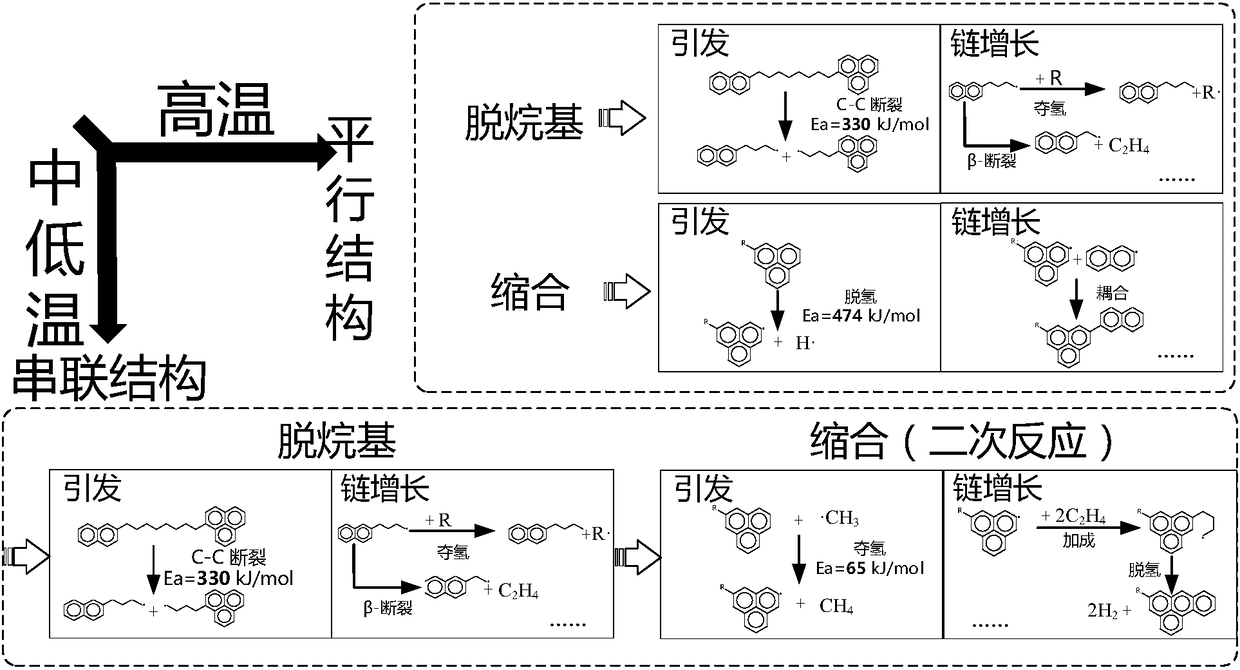

A visbreaking and supercritical technology, applied in the petroleum industry, refining hydrocarbon oil, etc., which can solve the problems of low visbreaking efficiency, rising, quenching of alkyl carbon radicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Visbreaking in supercritical benzene environment:

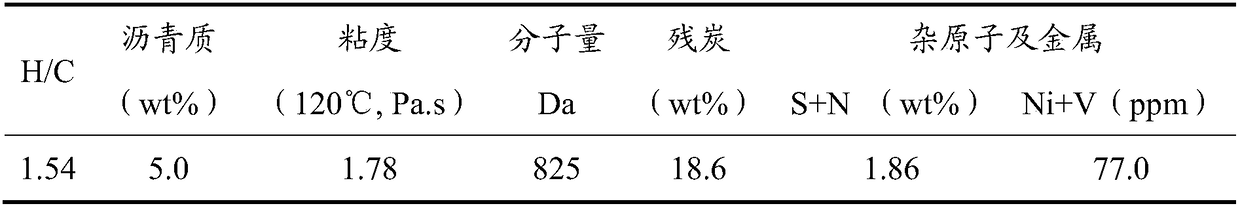

[0040] Add 10 g of raw material heavy oil (properties as shown in Table 1) and 30 g of benzene into a high-pressure reactor with a capacity of 100 mL. The feeding conditions correspond to a benzene-oil ratio of 3:1 and a supercritical benzene density of 0.30 g / cm 3 ;

[0041] With high purity N 2 After purging for 10 minutes, the closed reactor was heated from room temperature at a rate of 15°C / min, and the stirring rate was maintained at 700rpm during the process;

[0042] Start timing after reaching the specified temperature of 360°C;

[0043] After completing the predetermined time reaction, the cracking is terminated by air-cooling the reactor body.

[0044] N 2 Traditional visbreaking control experiments in ambient conditions:

[0045] Add 30g of raw material oil in a high-pressure reactor with a capacity of 100mL;

[0046] After high-purity N 2 Filled with 8.0-9.0MPa high-purity N after purging 2 ;

[0047...

Embodiment 2

[0061] Visbreaking of heavy oil in supercritical benzene environment:

[0062] Add 8.8g of feedstock oil and 35g of benzene to a 100mL autoclave, corresponding to a benzene-oil ratio of 4:1 and a supercritical benzene density of 0.35g / cm 3 ;

[0063] With high purity N 2 After purging for 10 minutes, the closed reactor was heated from room temperature at a rate of 15°C / min, and the stirring rate was maintained at 700rpm during the process;

[0064] After reaching the specified temperature of 400°C, the cracking is terminated by air-cooling the reactor body.

[0065] N 2 Traditional visbreaking control experiments in ambient conditions:

[0066] Add 30g of raw material oil in a high-pressure reactor with a capacity of 100mL;

[0067] After high-purity N 2 Filled with 8.0-9.0MPa high-purity N after purging 2 ;

[0068] The closed reactor starts heating at a rate of 15°C / min from normal temperature, and the stirring rate is kept at 700rpm during the process;

[0069] Sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com