High-efficiency and non-corrosion car windshield washing agent and preparation method thereof

A windshield, non-corrosive technology, applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problems of complex dirt composition and high cleaning performance requirements of windshield cleaning agent, etc. Important market value and social value, broad market prospects, and the effect of simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

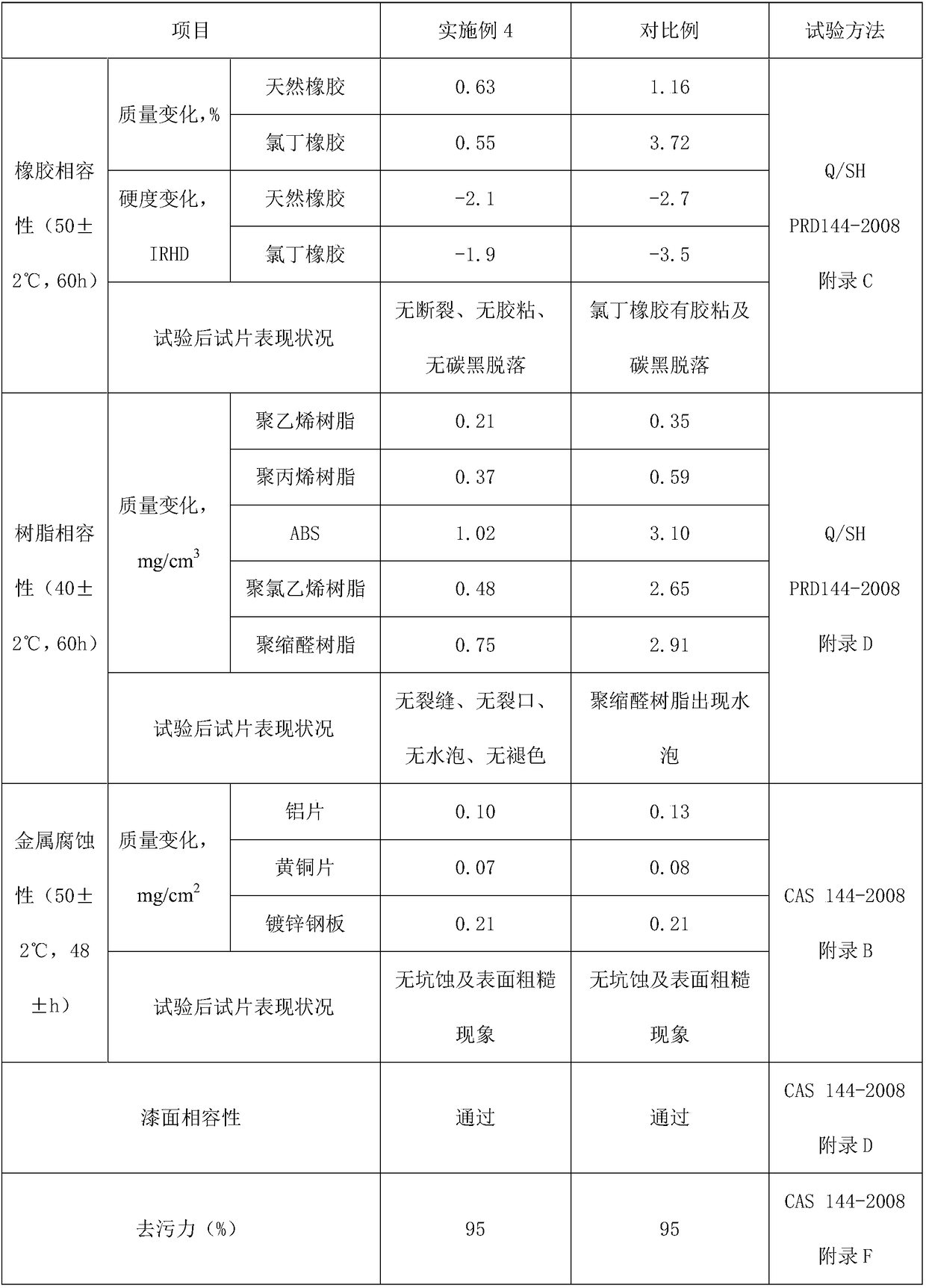

Examples

Embodiment 1

[0024] A highly efficient and non-corrosive car windshield cleaning agent, comprising the following raw materials in parts by weight: 120 parts of deionized water, 30 parts of ethanol, 0.6 part of polydimethylsiloxane, 1 part of benzyl benzoate, surface 2 parts of active agent, 0.3 part of preservative.

[0025] Wherein, the surfactant is composed of dioctyl sulfosuccinate sodium salt and isomeric alcohol polyoxyethylene ether in a weight ratio of 2:1; the preservative is methyl p-hydroxybenzoate.

[0026] In the present embodiment, the preparation method of the highly efficient and non-corrosive automobile windshield cleaning agent, the steps are as follows:

[0027] 1) Take a total amount of 20% deionized water and a total amount of 60% ethanol, stir and mix at 200 rpm for 10 minutes to obtain a mixed solution A;

[0028] 2) Weigh benzyl benzoate and preservative, add to mixed solution A, stir and mix at 600rpm for 15min, discharge, then send into ultrasonic processor, ultr...

Embodiment 2

[0033] A highly efficient and non-corrosive automotive windshield cleaning agent, comprising the following raw materials in parts by weight: 122 parts of deionized water, 35 parts of ethanol, 0.9 part of polydimethylsiloxane, 1.8 parts of benzyl benzoate, surface 3 parts of active agent, 0.6 part of preservative.

[0034] Wherein, the surfactant is composed of dioctyl sulfosuccinate sodium salt and isomeric alcohol polyoxyethylene ether in a weight ratio of 2:1; the preservative is methyl p-hydroxybenzoate.

[0035] In the present embodiment, the preparation method of the highly efficient and non-corrosive automobile windshield cleaning agent, the steps are as follows:

[0036] 1) Take a total amount of 25% deionized water and a total amount of 60% ethanol, stir and mix at 200 rpm for 12 minutes to obtain a mixed solution A;

[0037] 2) Weigh benzyl benzoate and preservative, add to mixed solution A, stir and mix at 700rpm for 16min, discharge, then send into ultrasonic proce...

Embodiment 3

[0042] A highly efficient and non-corrosive car windshield cleaning agent, comprising the following raw materials in parts by weight: 127 parts of deionized water, 34 parts of ethanol, 0.9 part of polydimethylsiloxane, 1 part of benzyl benzoate, surface Active agent 3.5 parts, preservative 0.6 parts.

[0043] Wherein, the surfactant is composed of dioctyl sulfosuccinate sodium salt and isomeric alcohol polyoxyethylene ether in a weight ratio of 2:1; the preservative is methyl p-hydroxybenzoate.

[0044] In the present embodiment, the preparation method of the highly efficient and non-corrosive automobile windshield cleaning agent, the steps are as follows:

[0045] 1) Take a total amount of 25% deionized water and a total amount of 65% ethanol, stir and mix at 400 rpm for 12 minutes to obtain a mixed solution A;

[0046] 2) Weigh benzyl benzoate and preservative, add to mixed solution A, stir and mix at 800rpm for 16min, discharge, then send into ultrasonic processor, ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com