Preparation method of cattle-hide collagen fibers as well as prepared cattle-hide collagen fibers and application thereof

A collagen fiber and cowhide glue technology, applied in the textile field, can solve the problems of large fiber damage, insufficient fiber quality, short length of cowhide collagen fibers, etc., to reduce physical damage and pressure, inhibit Staphylococcus aureus, The effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The invention provides a method for preparing cowhide collagen fibers. The preparation method comprises firstly softening the cowhide leather, then unrelaxing the softened cowhide to obtain cowhide collagen fiber bundles, and then subjecting the cowhide collagen fiber bundles to an opening process. Finally, the step of obtaining cowhide collagen fibers; wherein the softening treatment includes the step of stirring and spinning the cowhide while soaking in water; the opening treatment includes the step of using elastic materials to loosen the cowhide collagen fiber bundles. The cowhide collagen fiber prepared by this method has a fiber-making rate as high as 60% to 90%, has excellent physical and mechanical properties, and has excellent antibacterial and deodorant, moisture absorption and quick-drying, warm and breathable, natural flame retardant, skin-friendly and health-preserving functions. .

[0056] The step of softening treatment in the preparation method of cowhid...

Embodiment 1- Embodiment 41

[0098] Embodiment 1-embodiment 41 provides a kind of preparation method of cowhide collagen fiber, and described preparation method comprises the steps:

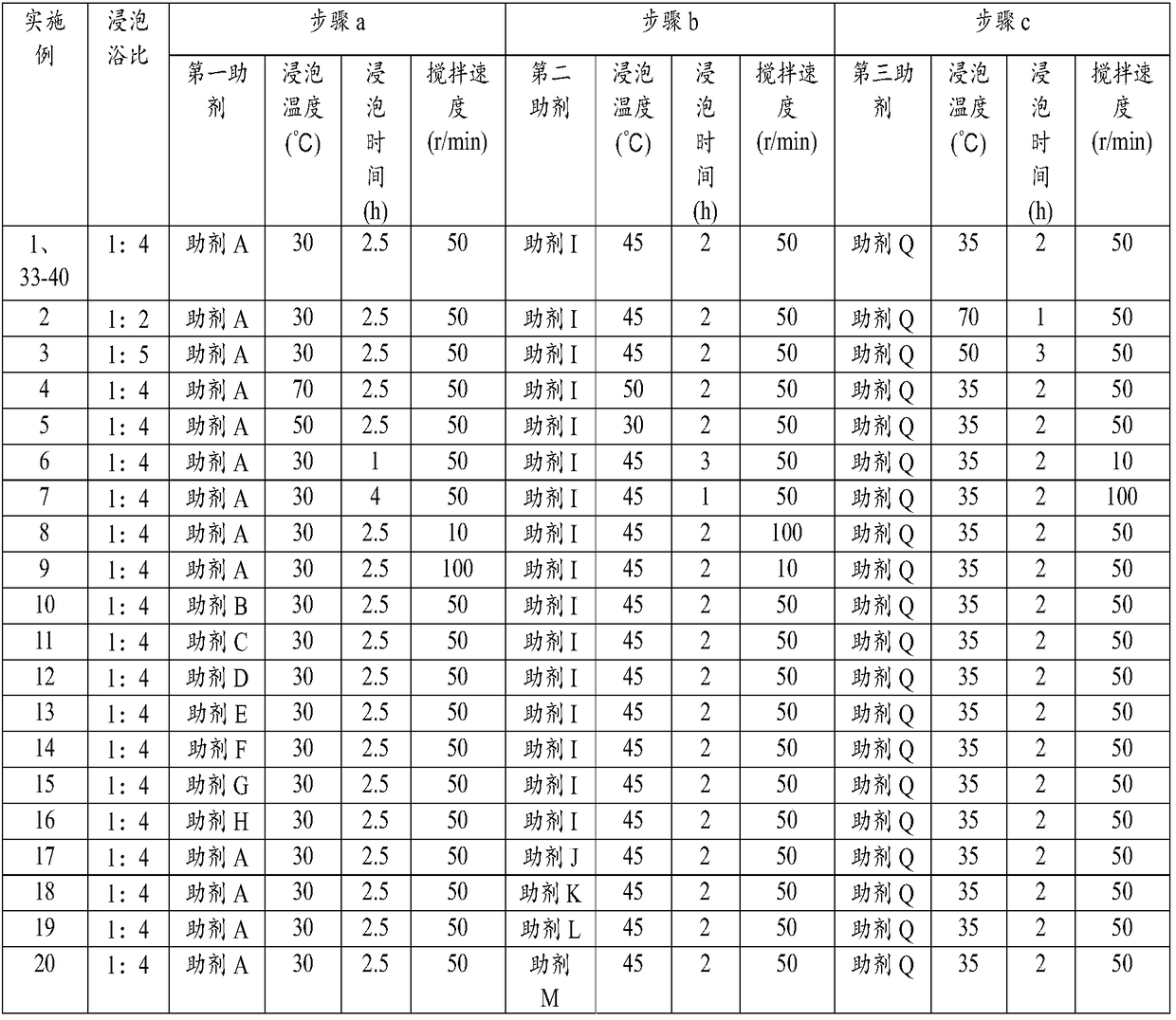

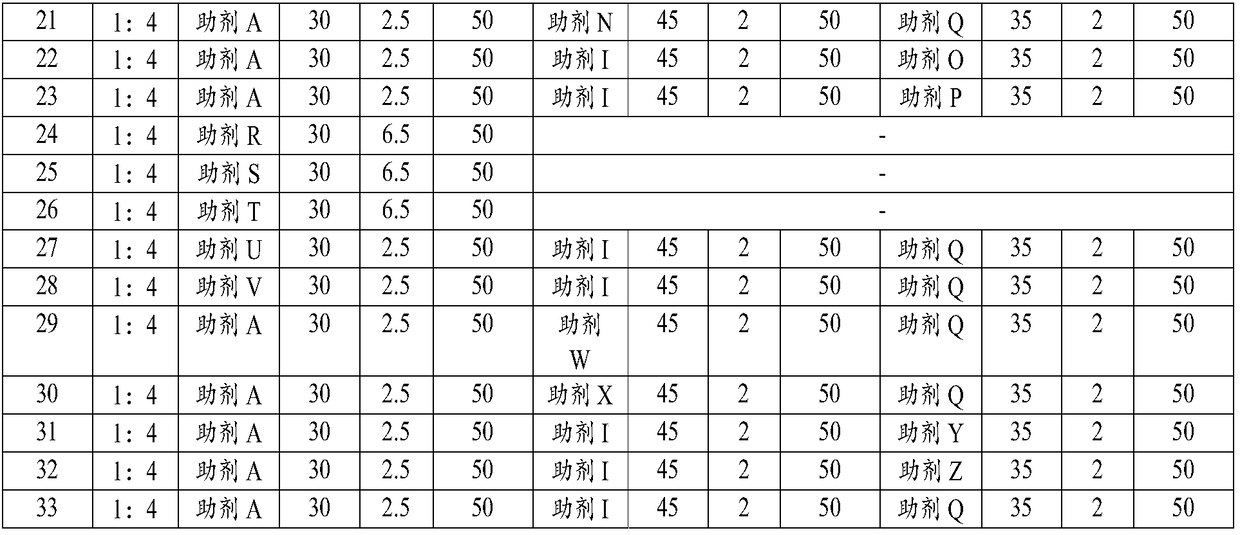

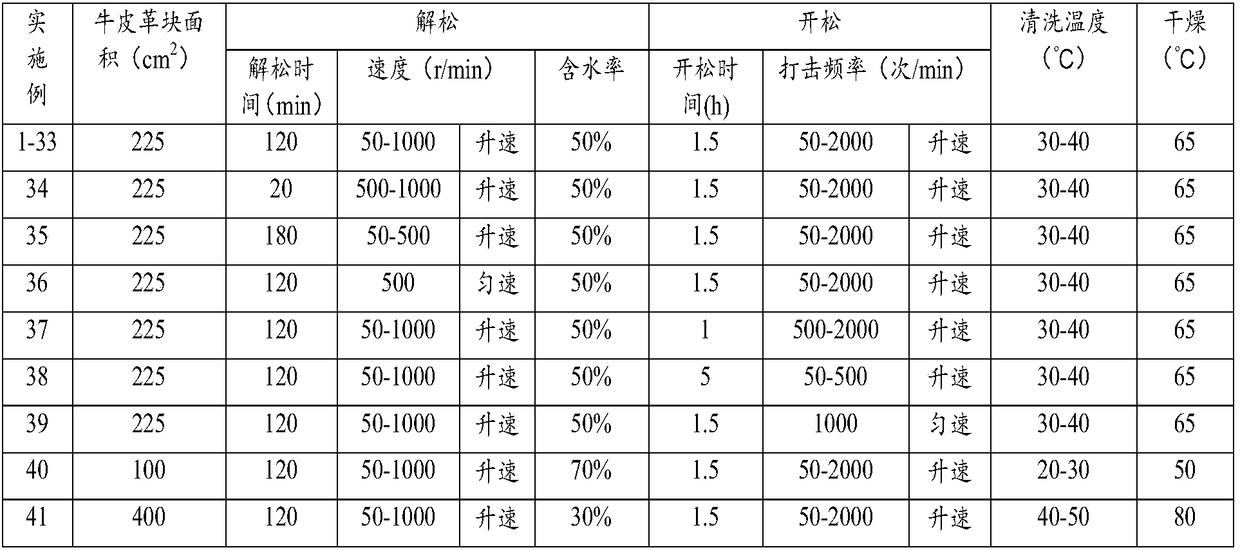

[0099] Select waste cowhide with basically the same thickness to cut the cowhide according to the process parameters provided in Table 2. The cut cowhide is stirred and softened while soaking in water. The soaking treatment method and process parameters are shown in Table 1. Show, the formula of auxiliary agent is as shown in table 3, and wherein, table 3 represents per 100 parts of water, adds the parts by weight of the component of each auxiliary agent;

[0100] In the preparation method provided in Example 33, the cowhide is stirred by turbine stirring, and in the other examples, it is stirred in a rotating pot equipped with a stirring rod with a spike, and then the softened and expanded cowhide is loosened-opened Steps of loosening-cleaning and separation-finishing-drying-secondary opening;

[0101] First, the softened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com