Cleaning machine booster pump

A technology of booster pump and washing machine, applied in the direction of pump, pump control, pump components, etc., can solve the problems of large friction resistance of plunger, easy water leakage volume, complex structure, etc., to reduce volume, not easy to leak water, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

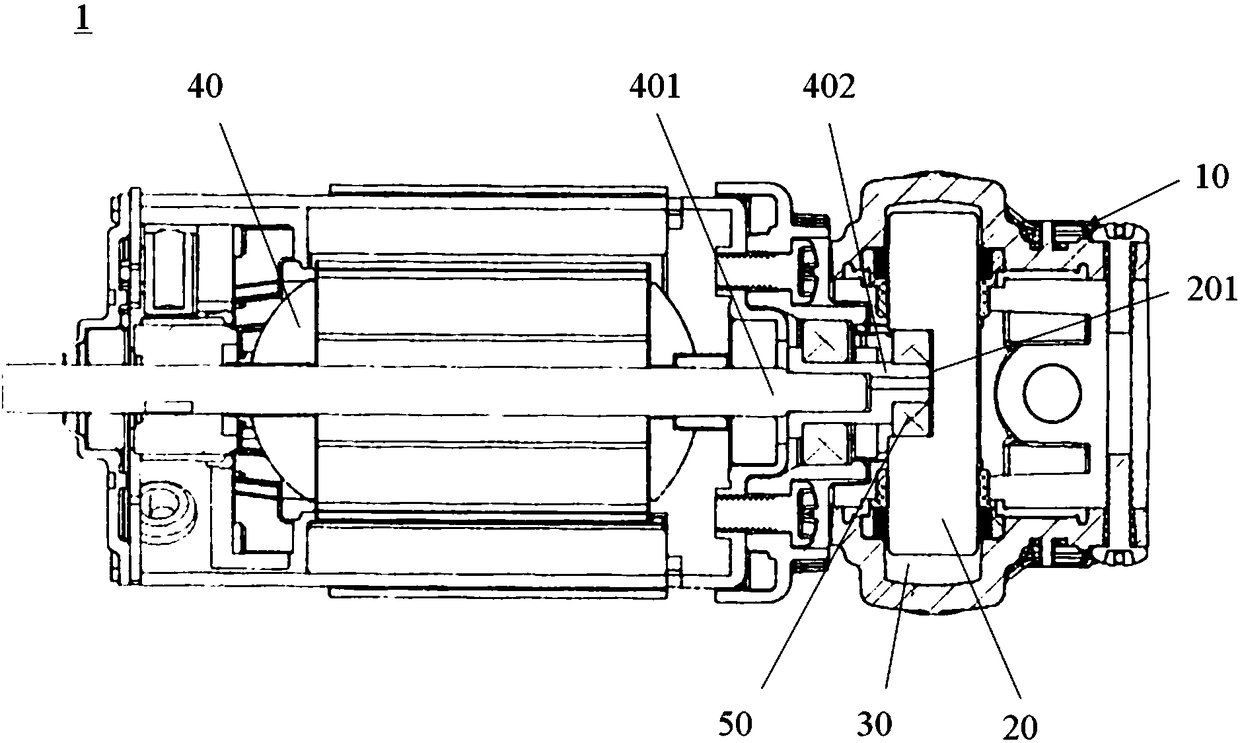

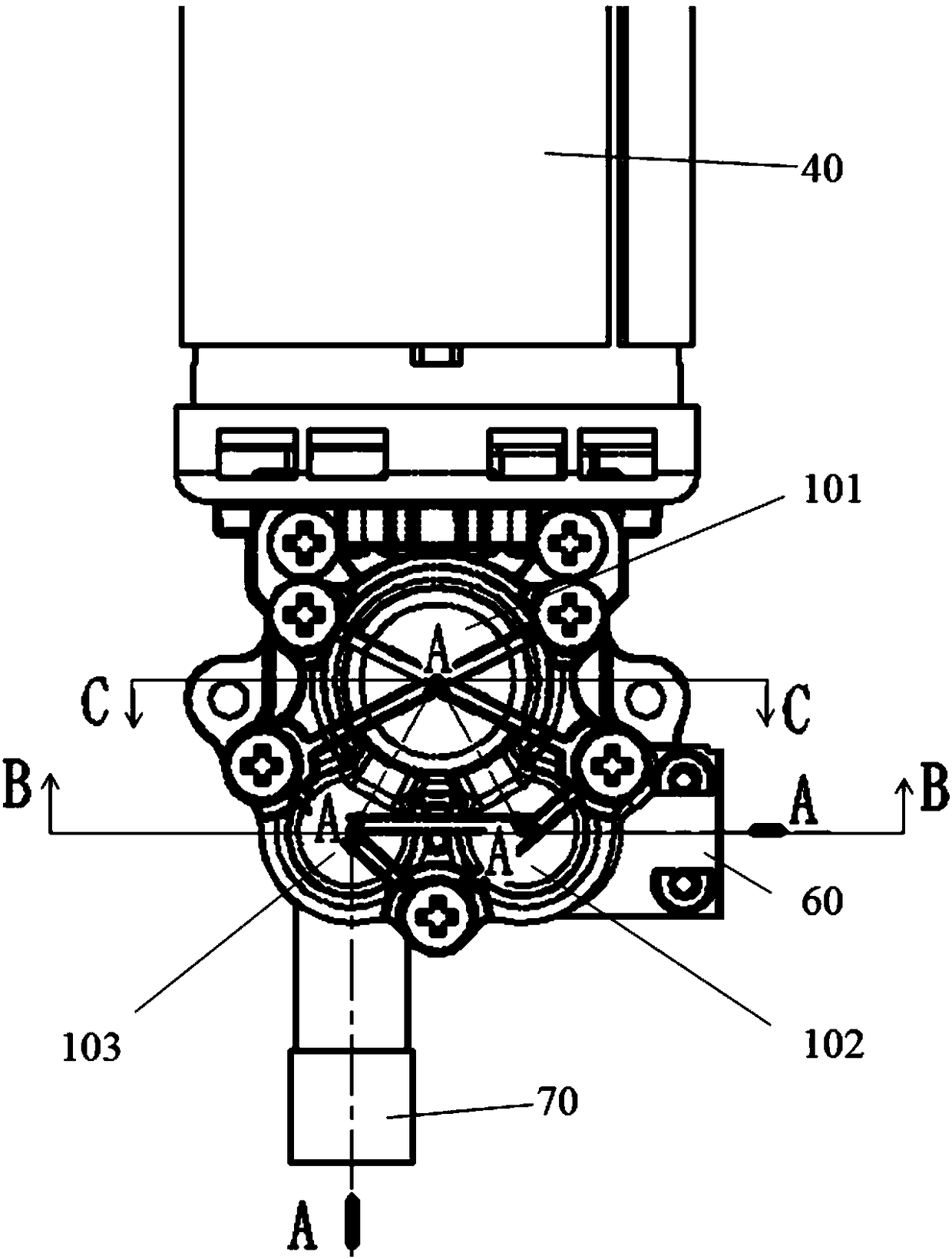

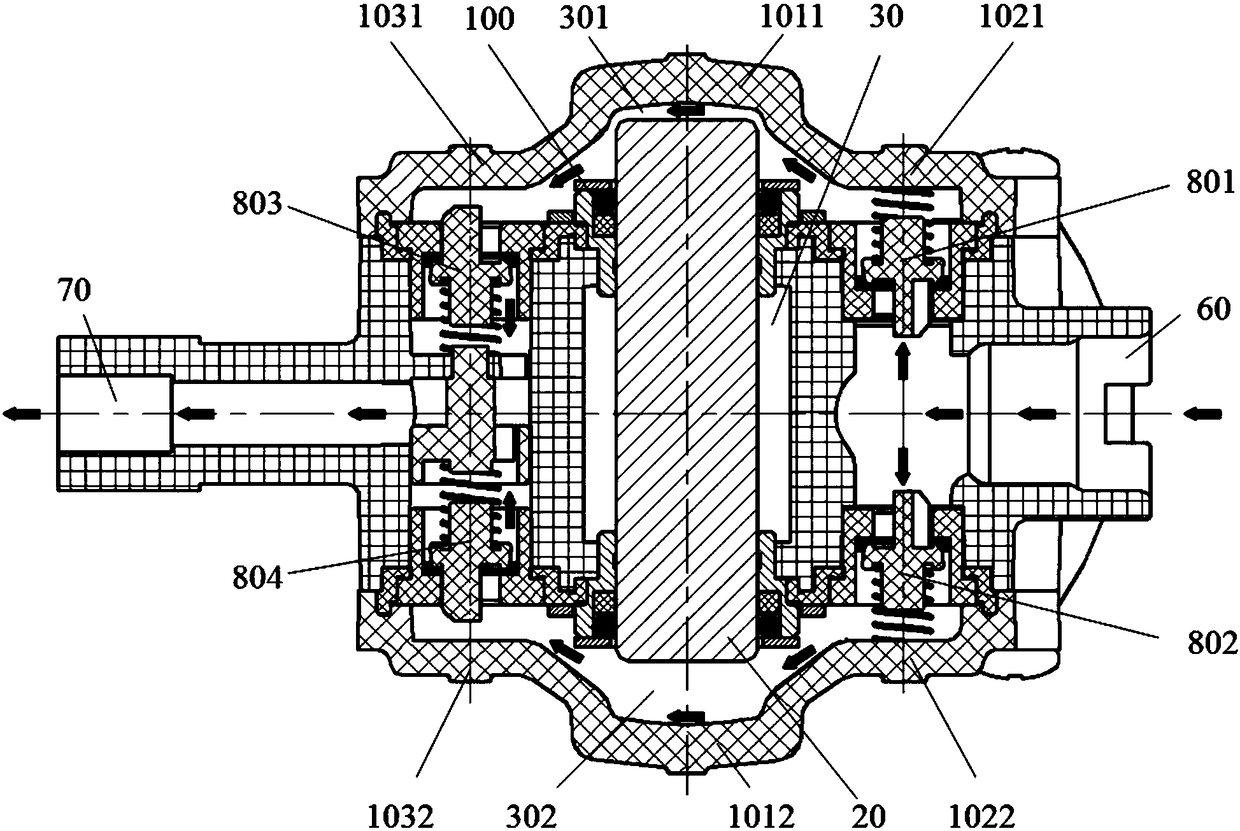

[0062] figure 1 A schematic structural diagram of a booster pump for a washing machine according to an embodiment of the present invention is shown. like figure 1 As shown, the washing machine booster pump 1 may include a housing 10 , a plunger 20 and an accommodating space 30 formed in the housing 10 . The plunger 20 is suspended in the accommodating space 30 . The accommodating space 30 extends along the axial direction of the plunger 20 . The plunger 20 divides the accommodation space 30 at its two ends into two pressurized chambers.

[0063] In one embodiment, such as figure 1 As shown, the plunger 20 includes a recess 201 . The recess 201 extends to the outer surface of the plunger 20 and is symmetrical with respect to a center line perpendicular to the axial direction of the plunger 20 . The washing machine booster pump 1 can also include a motor 40 . The motor 40 can be a DC motor, a series motor or a brushless motor. The motor 40 may include an output shaft 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com