Support hoisting mechanism and hoisting system

A technology for hoisting and supporting components, which is applied in the direction of erecting/assembling bridges, cranes, bridges, etc., which can solve problems such as narrow distances, damage to steel beams, and inadvisability, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

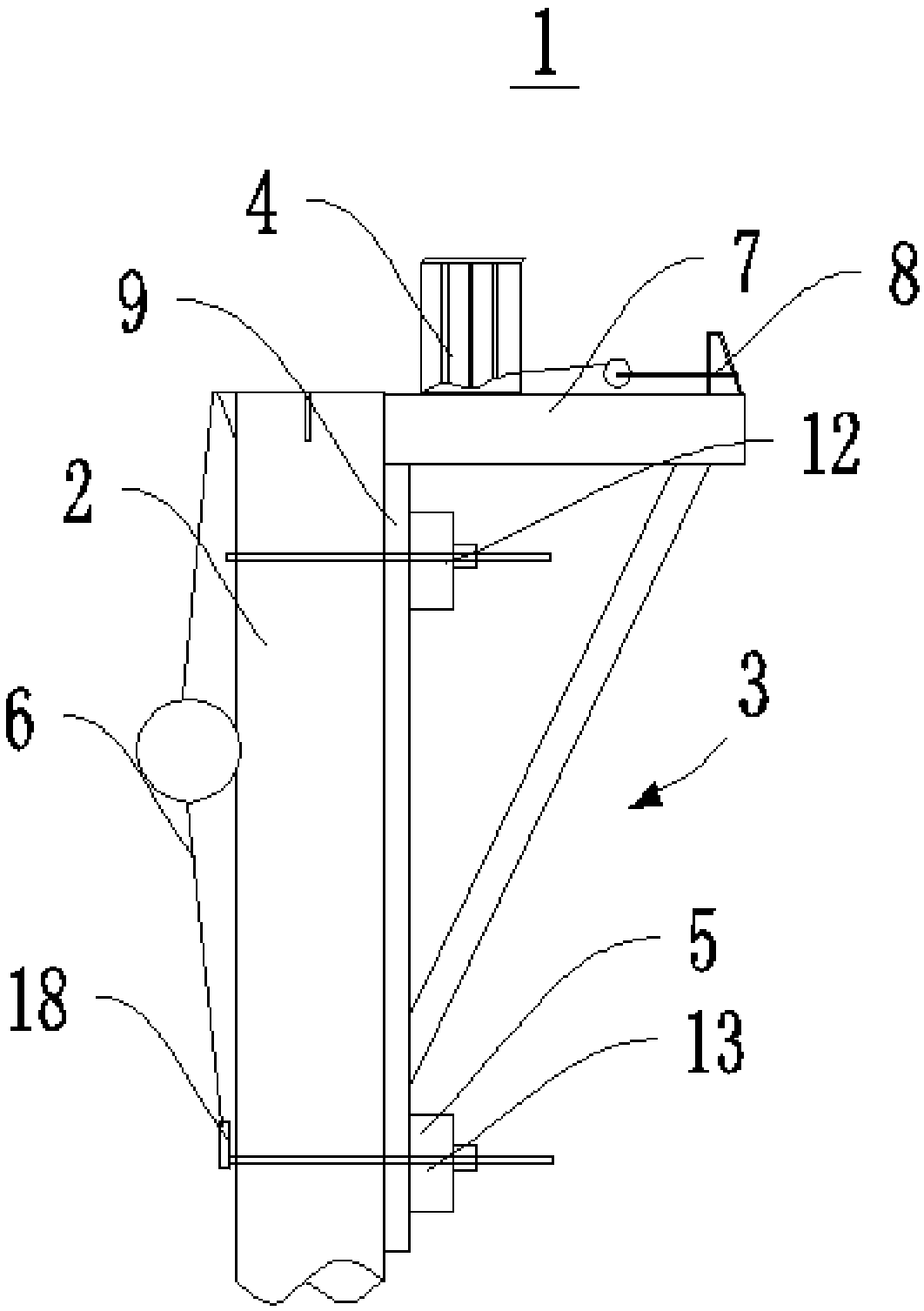

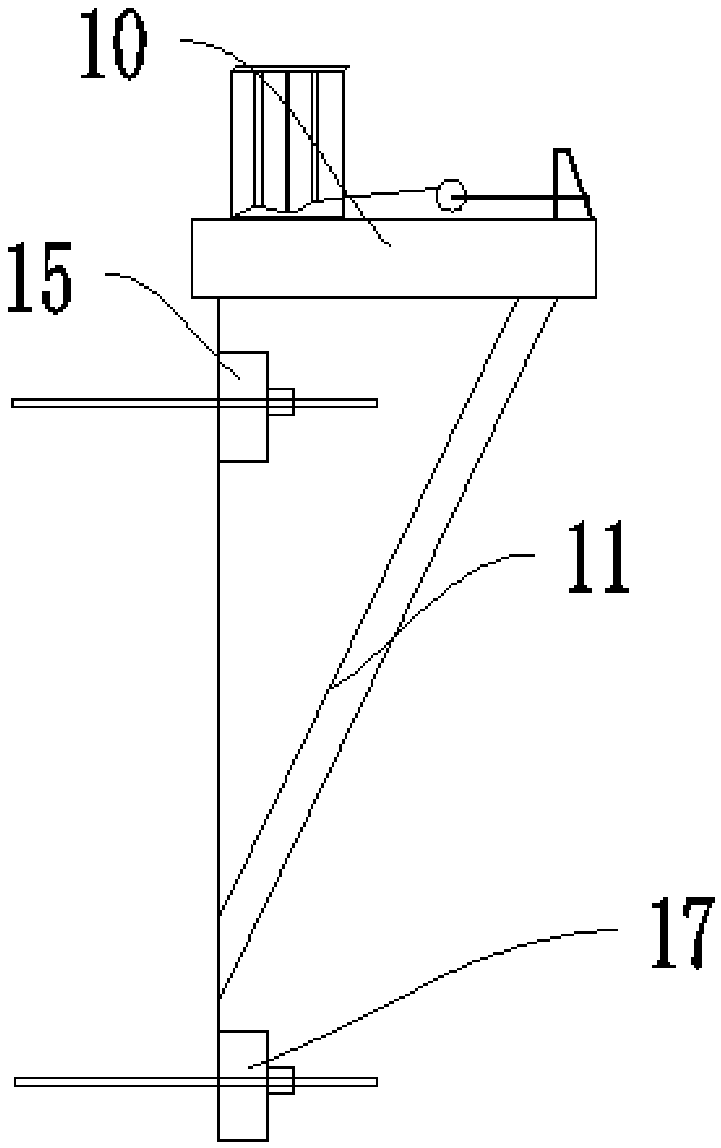

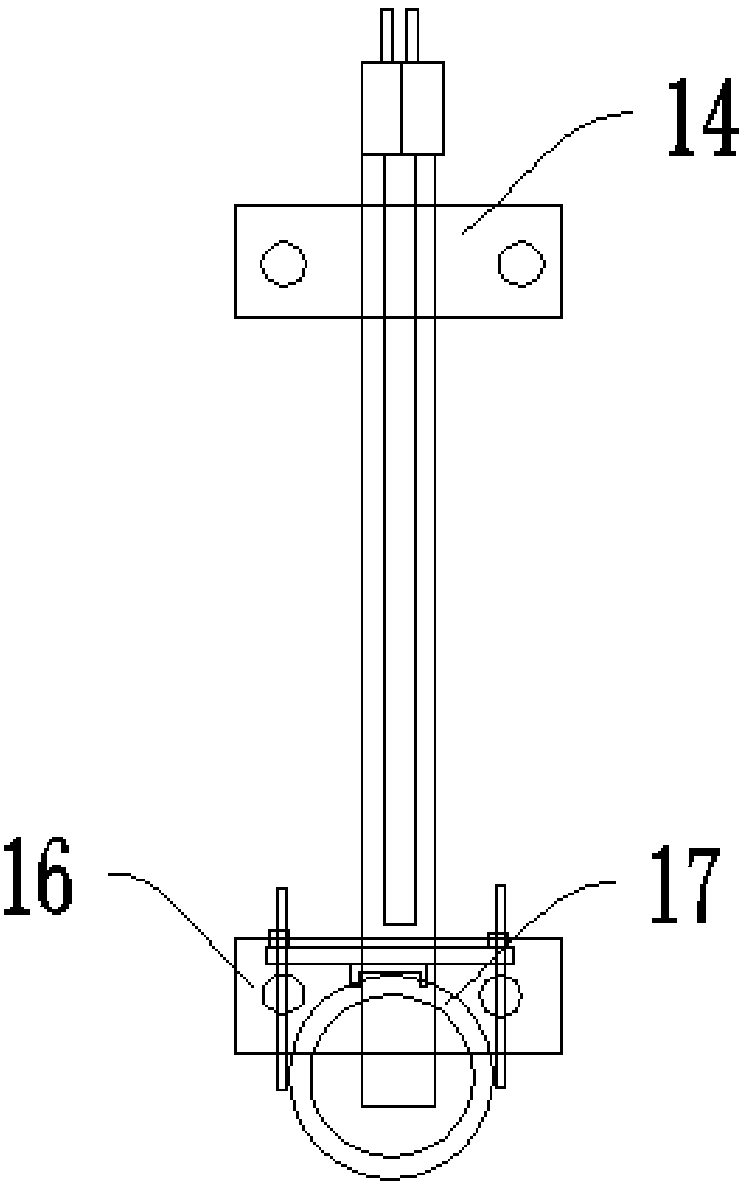

[0033] This embodiment provides a hoisting system, which includes a bracket hoisting mechanism 1 .

[0034] see Figure 1 to Figure 4 The bracket hoisting mechanism 1 includes a column 2, a hoisting assembly 3 and an I-beam 4, the hoisting assembly 3 includes a connecting member 5, an inverted chain 6, a support member 7 and a tensioner 8; the I-beam 4 is movably arranged on the column 2 Above; the support member 7 is movably installed on the column 2 through the connecting member, the upright chain 6 is installed on one side of the upright 2 , the upside down chain 6 is connected with the support member 7 in transmission, and the uplink 6 can drive the support member 7 along the upright column 2 The tension device 8 is installed on the support member 7, and the tension device 8 is connected with the I-beam 4 in transmission, and the tension device 8 can pull the I-beam 4 to the support member 7.

[0035] Further, in this embodiment, the support member 7 includes a buttress c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com