Drop energy dissipating shaft for sand setting pretreatment

A technology for pretreatment and energy dissipation wells, applied in water/sewage treatment, water/sludge/sewage treatment, water supply devices, etc., it can solve the problem of lack of water-drop energy dissipation shafts, achieve clear functional division and reduce construction difficulty , The effect of reducing the workload of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

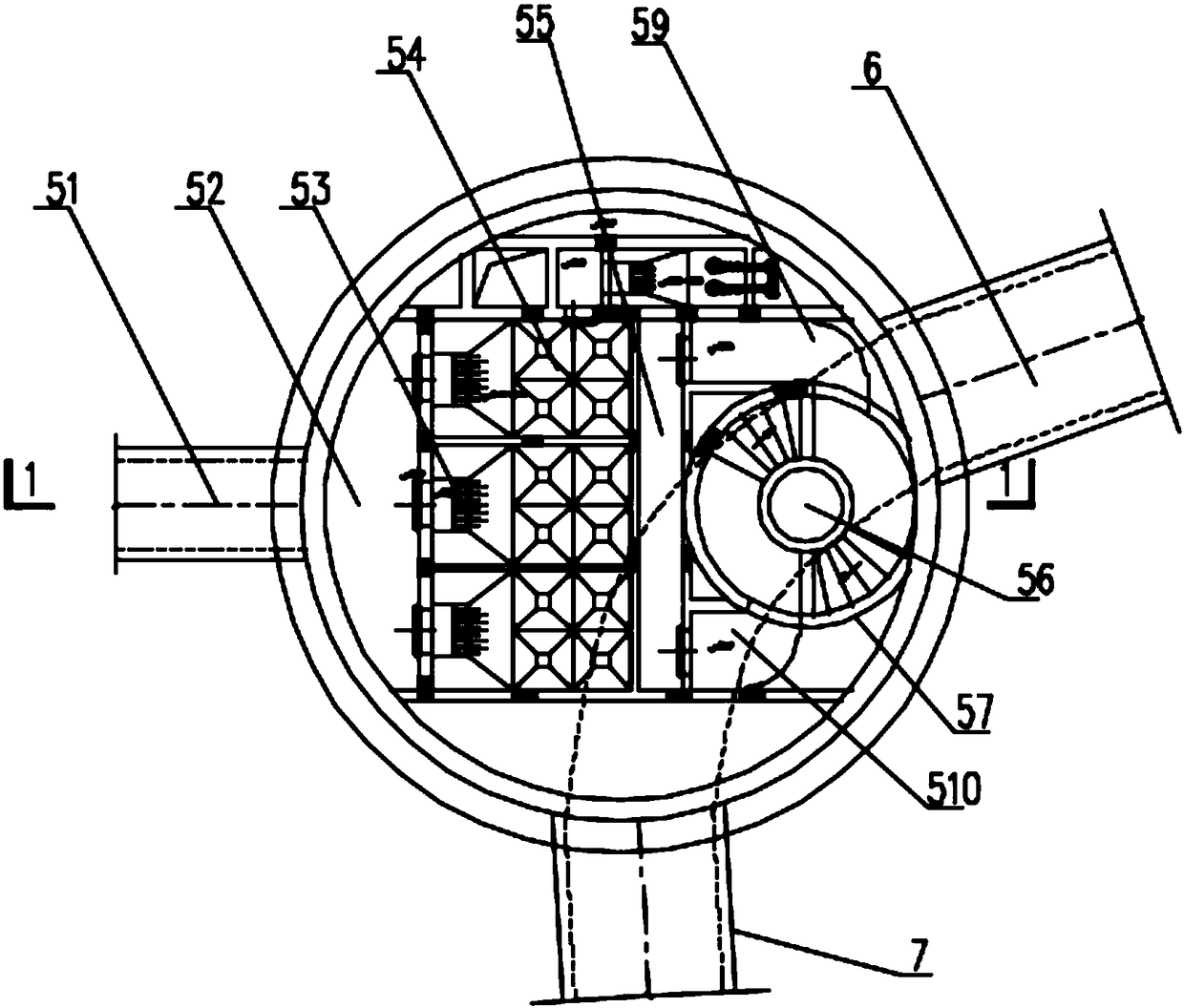

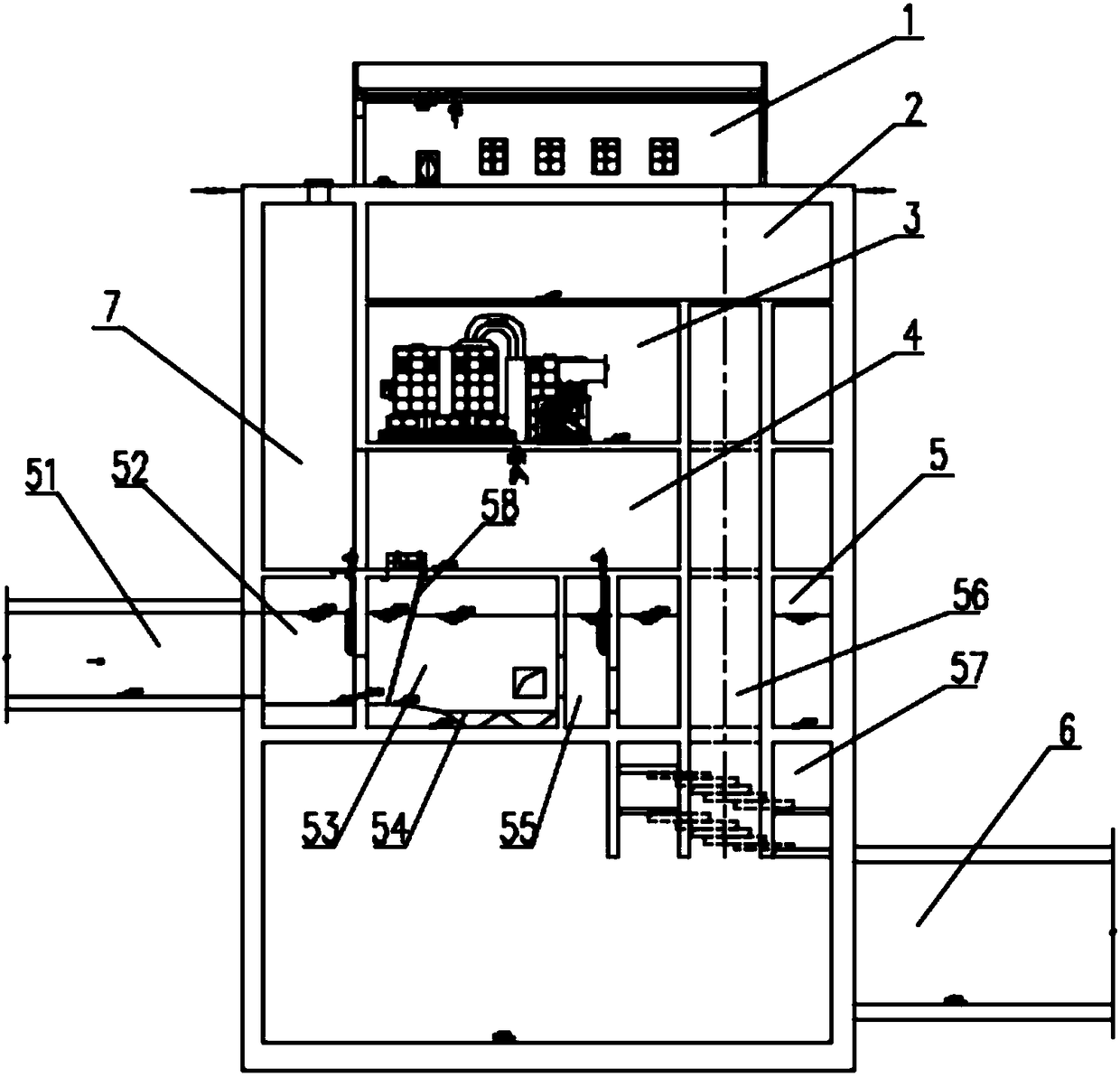

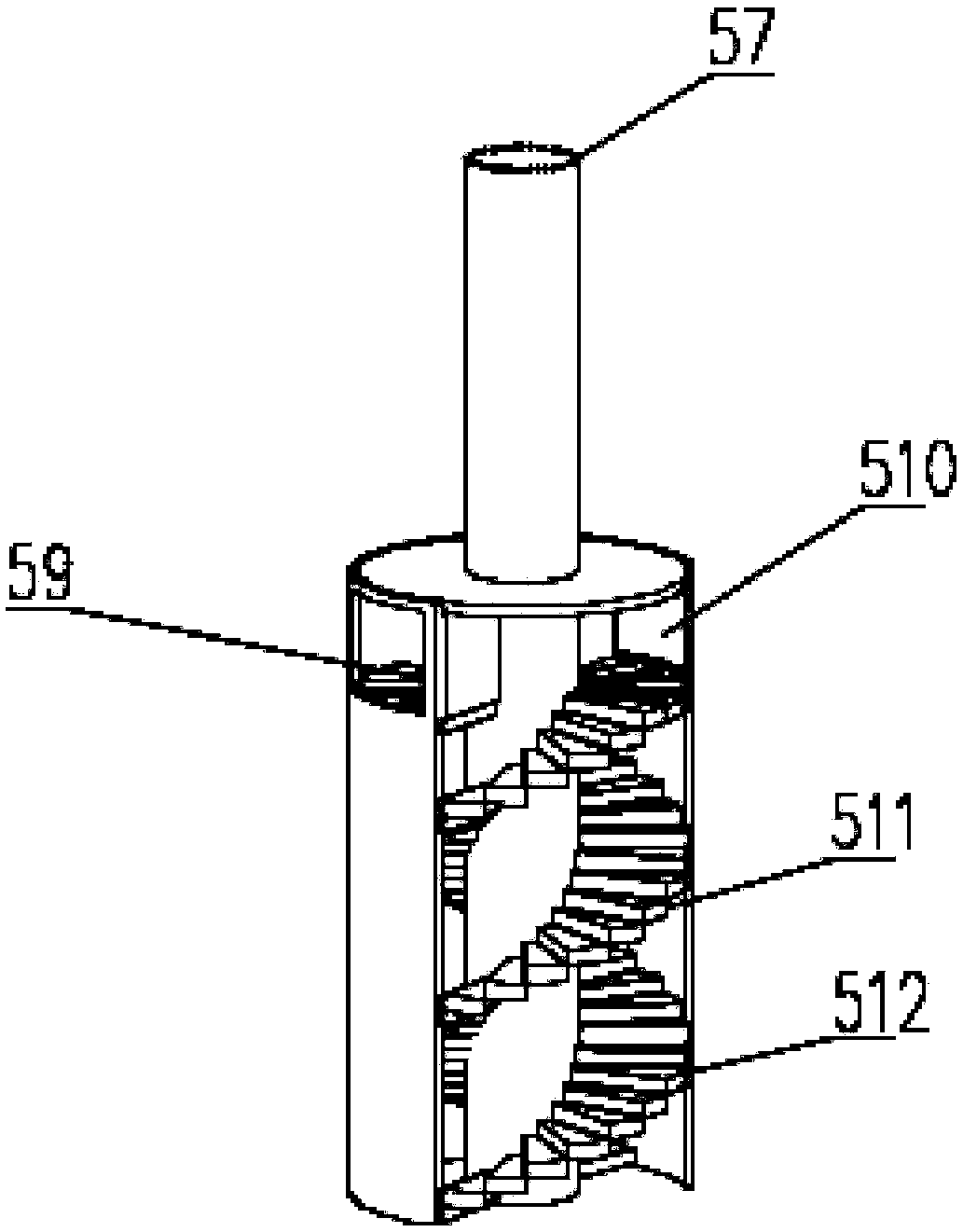

[0028] like Figure 1 to Figure 3 As shown, a kind of falling water energy dissipation vertical shaft for sand pretreatment of the present invention includes a management room 1, a ventilation equipment room 2, a deodorizing equipment room 3, an operation room 4, and a falling water energy dissipation room 5 from top to bottom. And the deep storage tunnel 6, the falling water energy dissipation room 5 includes the water inlet pipe 51, the water inlet well 52, the grid room 53, the catchment channel 55 and the energy dissipation well 57, which are connected successively, and the grid room 53 A grit chamber 54 and a grab-type grille 58 are provided, the grit chamber 54 is arranged at the bottom of the grill room 53, and the grab-type grill 58 is arranged at the front end of the grill room 53 where the water enters, so The energy dissipation well 57 described above is provided with a first water inlet 59, a second water inlet 510, a first energy dissipation ridge 511, a second en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com