Sewing die and method for strip-shaped composite preform

A technology for preforms and composite materials, which is applied in the field of manufacture of strip composite material preforms, can solve the problems of difficulty in guarantee, high dimensional accuracy, bending, etc., and achieves high compactness, high fiber volume content and high size The effect of precision and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

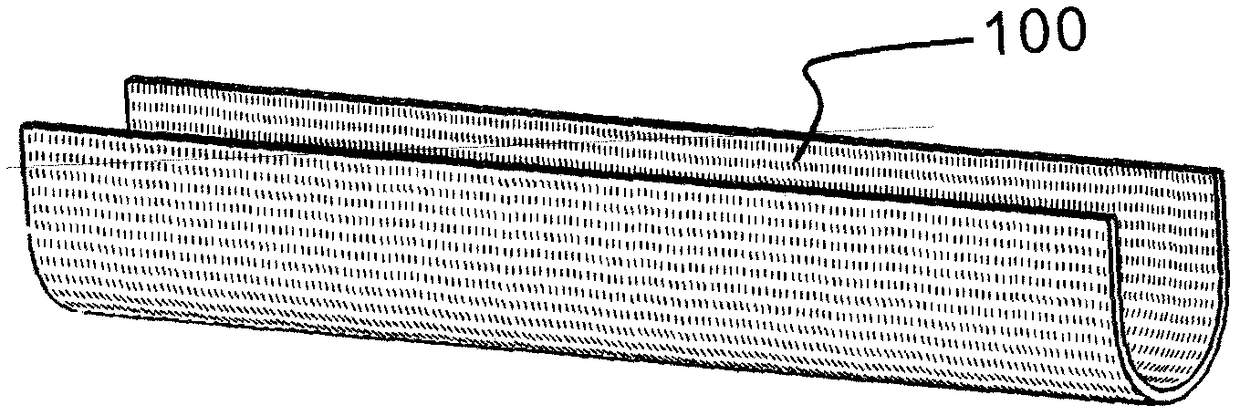

[0030] The final molded part of this embodiment is a U-shaped carbon fiber composite material preform 100, the length of the preform is 780mm, and the thickness is 10mm, such as figure 1 As shown, the ply angle is [0°, 90°].

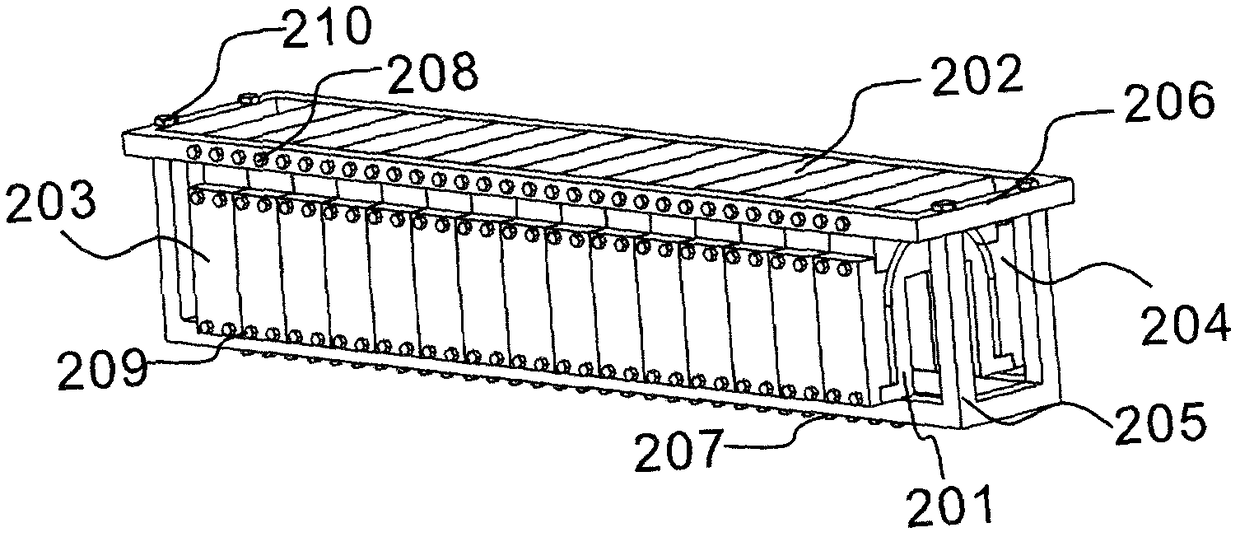

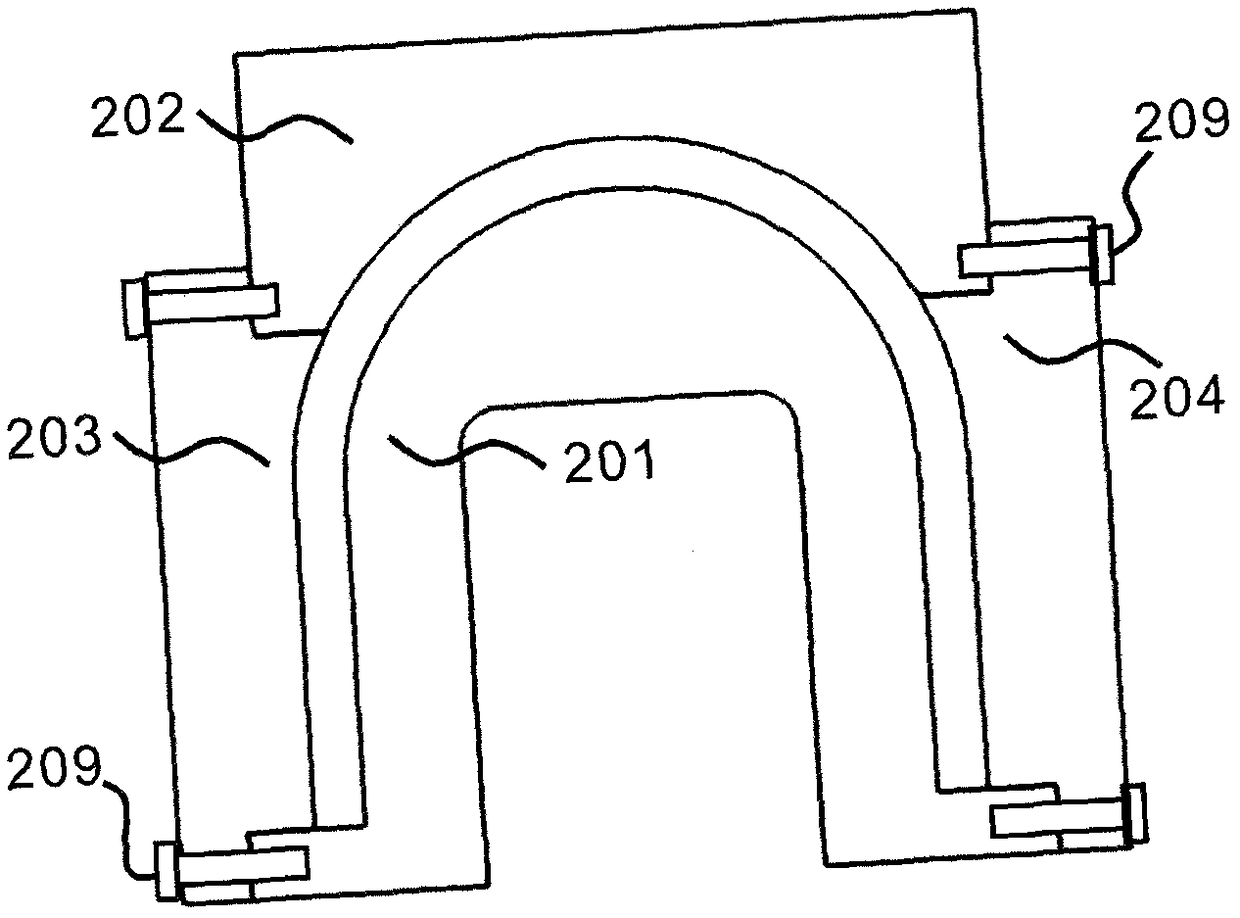

[0031] The sewing mold 200 of preform 100, see figure 2 shown. In the direction of the preforming section, the mold 200 is composed of a core mold 201, a bottom mold 202, a left mold 203 and a right mold 204, and the cross-sectional view of the mold is as follows image 3 shown. Mandrel 201, bottom mold 202, left side mold 203 and right side mold 204 are all made up of 15 pieces in the lengthwise direction of mould, and each piece length is 60mm (the length of preform is 780mm, and the middle 13 pieces The part corresponding to the pieces is the preform that actually needs to be stitched, and the two sets of pieces at the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com