Plastic carpet with massage effect and preparation method of plastic carpet

A carpet and plastic technology, applied in the field of plastic products, can solve the problems of bacterial diseases and insects affecting health, no massage effect, complicated procedures, etc., so as to relieve the nerves of the soles of the feet, good ventilation and heat dissipation, and good ventilation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

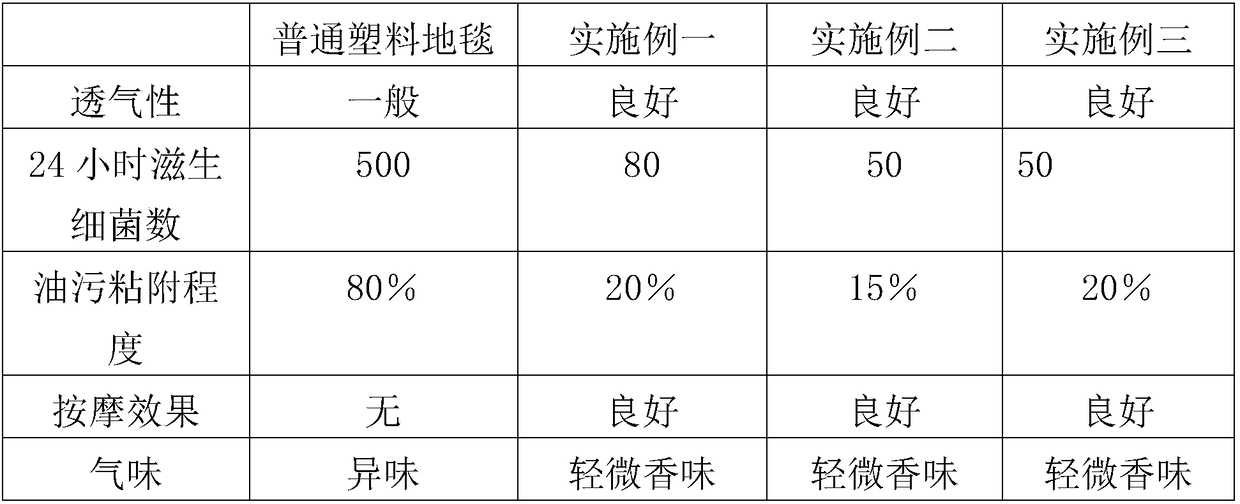

Examples

Embodiment 1

[0033] A plastic carpet with a massage effect, made of the following components in parts by weight: 100 parts by weight of PVC, 40 parts by weight of polytetrafluoroethylene, 4 parts by weight of plasticizer, 6 parts by weight of softener, 10 parts by weight of pigment, and stabilizer 1 part by weight, 4 parts by weight of adhesive, 10 parts by weight of pebbles, 6 parts by weight of essential oil, 10 parts by weight of hemp fiber, 4 parts by weight of geranium juice, 1 part by weight of nitrogen, and 20 parts by weight of distilled water.

[0034] A method for preparing a plastic carpet with a massage effect, characterized in that it comprises the following steps,

[0035] (1), the production of the main film, put PVC, plasticizer, softener, pigment and stabilizer into the mixer and fully mix, add the mixed raw materials into the high-temperature roller press, and obtain the main film after rolling;

[0036] (2) For facial mask production, put polytetrafluoroethylene, plastic...

Embodiment 2

[0055] A plastic carpet with a massage effect, made of the following components in parts by weight: 110 parts by weight of PVC, 50 parts by weight of polytetrafluoroethylene, 5 parts by weight of plasticizer, 8 parts by weight of softener, 15 parts by weight of pigment, and stabilizer 2 parts by weight, 5 parts by weight of adhesive, 15 parts by weight of pebbles, 8 parts by weight of essential oil, 15 parts by weight of hemp fiber, 5 parts by weight of geranium juice, 2 parts by weight of nitrogen, and 25 parts by weight of distilled water.

[0056] A method for preparing a plastic carpet with a massage effect, characterized in that it comprises the following steps,

[0057] (1), the production of the main film, put PVC, plasticizer, softener, pigment and stabilizer into the mixer and fully mix, add the mixed raw materials into the high-temperature roller press, and obtain the main film after rolling;

[0058] (2) For facial mask production, put polytetrafluoroethylene, plast...

Embodiment 3

[0077] A plastic carpet with a massage effect is made of the following components in parts by weight: 120 parts by weight of PVC, 60 parts by weight of polytetrafluoroethylene, 6 parts by weight of plasticizer, 10 parts by weight of softener, 20 parts by weight of pigment, and stabilizer 3 parts by weight, 6 parts by weight of adhesive, 20 parts by weight of pebbles, 10 parts by weight of essential oil, 20 parts by weight of hemp fiber, 6 parts by weight of geranium juice, 3 parts by weight of nitrogen, and 30 parts by weight of distilled water.

[0078] A method for preparing a plastic carpet with a massage effect, characterized in that it comprises the following steps,

[0079] (1), the production of the main film, put PVC, plasticizer, softener, pigment and stabilizer into the mixer and fully mix, add the mixed raw materials into the high-temperature roller press, and obtain the main film after rolling;

[0080] (2) For facial mask production, put polytetrafluoroethylene, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com