Production method for intermediate-frequency magnetic shielding silicon steel

A production method and magnetic shielding technology, applied in the field of metal materials, can solve the problems of limited production efficiency, high production cost, and brittleness of high silicon steel hot-rolled slab heating, oxidation and cold-rolling, so as to avoid edge cracking, reduce belt breakage, improve The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The weight percentage of the chemical composition of the steel in Example 1 of the present invention is: C: 0.003%, Si: 6.0%, Als: 0.15%, Mn: 0.25%, P: 0.02%, S: 0.003%, N: 0.0020%, and the rest are Iron and inevitable impurity elements. The detection results of Example 1 of the present invention are shown in Table 1.

[0024] The production method of intermediate frequency magnetic shielding silicon steel in Example 1 of the present invention includes smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0025] 1. The silicon content of molten steel is 3.0%, and the other components are smelted to the target composition.

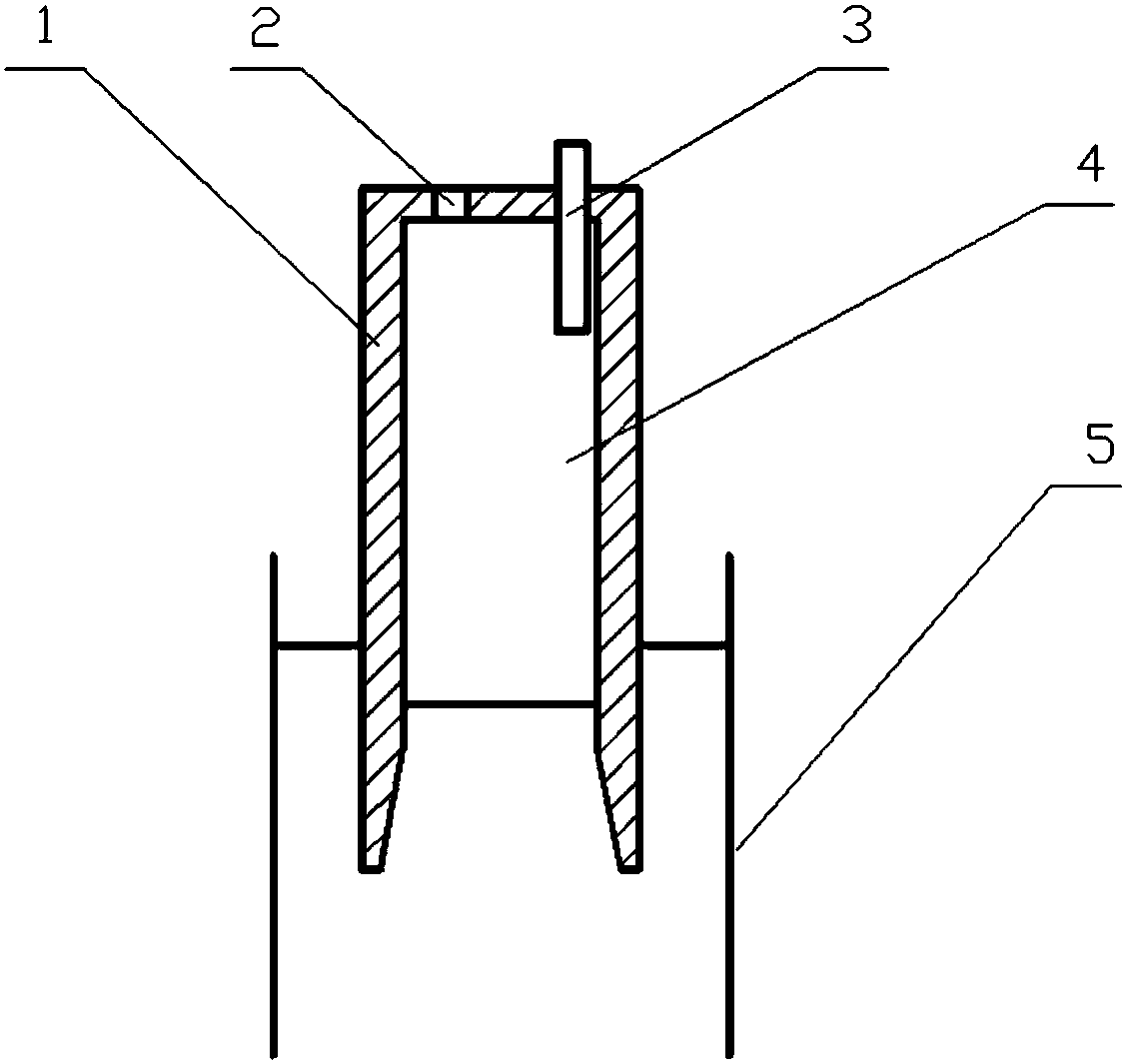

[0026] 2. The molten steel is cast into billets by continuous casting, with a superheat of 55℃. A feeding device 1 is provided in the continuous casting mold 5, one end of the feeding device 1 is open and the opening is downward, and the interior of the feeding device 1 is a cavity 4, and the f...

Embodiment 2

[0033] The weight percentage of the chemical composition of the steel in the embodiment of the present invention is: C: 0.003%, Si: 6.5%, Als: 0.05%, Mn: 0.30%, P: 0.01%, S: 0.003%, N: 0.0020%, and the rest is iron And unavoidable impurity elements.

[0034] The detection results of Example 2 of the present invention are shown in Table 2.

[0035] The production method of intermediate frequency magnetic shielding silicon steel in Example 2 of the present invention includes smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0036] 1. Smelt molten steel with a silicon content of 3.3%, and smelt other components to the target composition.

[0037] 2. The molten steel is cast into billets by continuous casting, with a superheat of 25℃. A feeding device 1 is added to the continuous casting mold 5, and the interior of the feeding device 1 is a cavity 4, one end of the feeding device 1 is open and the opening is downward, the ...

Embodiment 3

[0044] The weight percentage of the chemical composition of the steel in the embodiment of the present invention is: C: 0.003%, Si: 5.7%, Als: 0.22%, Mn: 0.45%, P: 0.015%, S: 0.0035%, N: 0.0020%, and the rest is iron And unavoidable impurity elements.

[0045] The detection results of Example 3 of the present invention are shown in Table 3.

[0046] The method for producing intermediate frequency magnetic shielding silicon steel in Example 3 of the present invention includes smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0047] 1. Smelt molten steel with a silicon content of 3.1%, and smelt other components to the target composition.

[0048] 2. Using continuous casting method to cast molten steel into billets, the superheat of molten steel is 40℃. A feeding device 1 is added to the continuous casting mold 5, the interior of the feeding device 1 is a cavity 4, one end of the feeding device 1 is open and the opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com