A kind of production method of medium frequency magnetic shielding silicon steel

A production method and magnetic shielding technology, which are applied in the field of metal materials, can solve the problems of brittleness, limited production efficiency, and high production cost of high-silicon hot-rolled hot-rolled slabs during heating, oxidation, and cold-rolling, so as to improve processing performance, reduce belt breakage, and avoid edge cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The weight percent of the chemical composition of steel in Example 1 of the present invention is: C: 0.003%, Si: 6.0%, Als: 0.15%, Mn: 0.25%, P: 0.02%, S: 0.003%, N: 0.0020%, and the rest are Iron and unavoidable impurity elements. The detection results of Example 1 of the present invention are shown in Table 1.

[0024] Embodiment 1 of the present invention is a production method of intermediate frequency magnetically shielded silicon steel, including smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0025] 1. The silicon content of molten steel is smelted to 3.0%, and other components are smelted to target components.

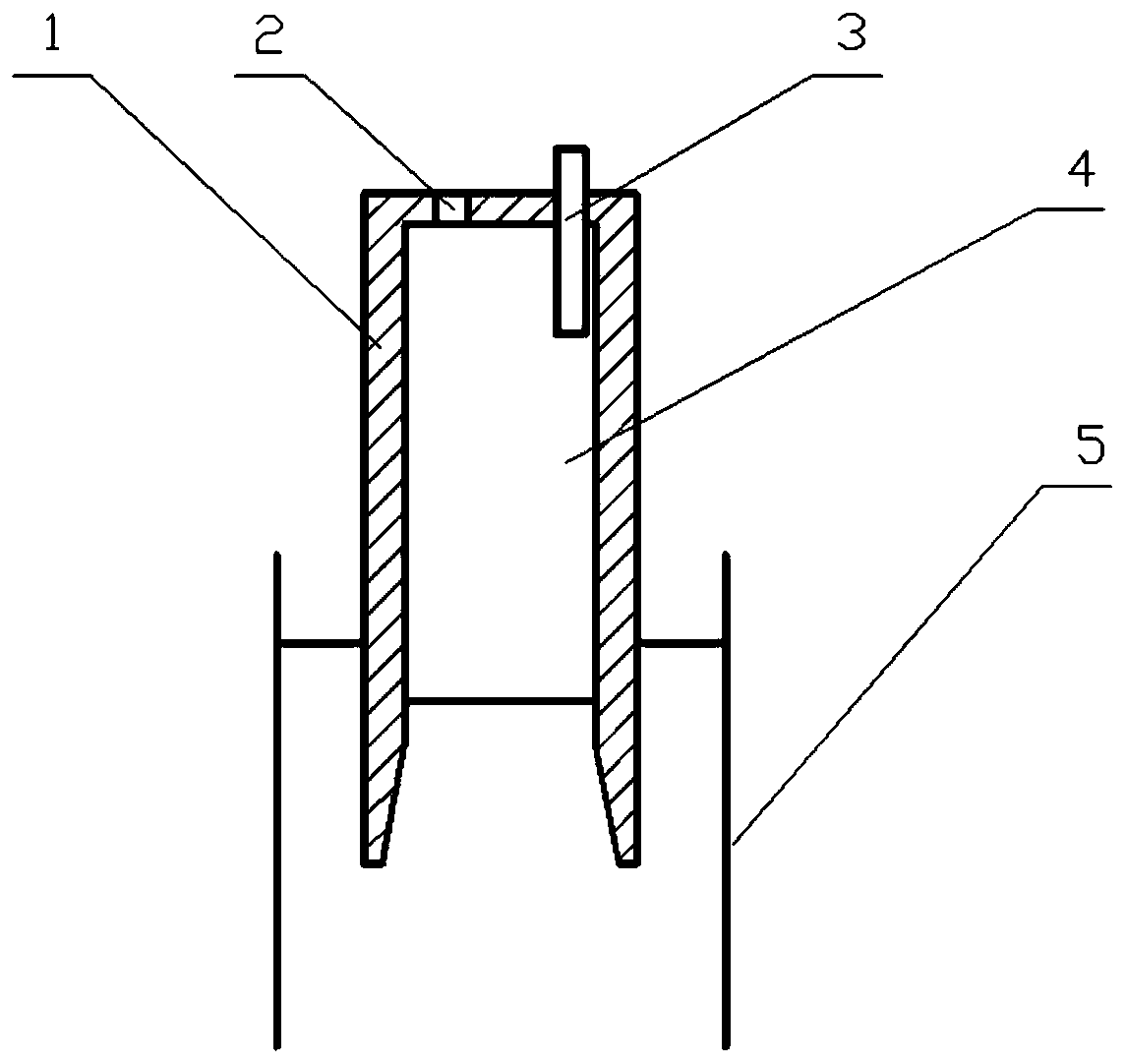

[0026] 2. Continuous casting is used to cast molten steel into billets, and the superheat of molten steel is 55°C. A feeding device 1 is arranged in the continuous casting crystallizer 5. One end of the feeding device 1 is open and the opening is downward. The inside of the feeding dev...

Embodiment 2

[0033] The weight percent of the chemical composition of steel in the embodiment of the present invention is: C: 0.003%, Si: 6.5%, Als: 0.05%, Mn: 0.30%, P: 0.01%, S: 0.003%, N: 0.0020%, and the rest is iron and unavoidable impurity elements.

[0034] The detection results of Example 2 of the present invention are shown in Table 2.

[0035] Embodiment 2 of the present invention is the production method of intermediate frequency magnetically shielded silicon steel, including smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0036] 1. The silicon content of molten steel is smelted to 3.3%, and other components are smelted to target components.

[0037] 2. Continuous casting is used to cast molten steel into billets, and the superheat of molten steel is 25°C. A feeding device 1 is added in the continuous casting crystallizer 5. The inside of the feeding device 1 is a cavity 4. One end of the feeding device 1 is o...

Embodiment 3

[0044] The weight percent of the chemical composition of steel in the embodiment of the present invention is: C: 0.003%, Si: 5.7%, Als: 0.22%, Mn: 0.45%, P: 0.015%, S: 0.0035%, N: 0.0020%, and the rest is iron and unavoidable impurity elements.

[0045] The detection results of Example 3 of the present invention are shown in Table 3.

[0046] Embodiment 3 of the present invention is a production method of intermediate frequency magnetically shielded silicon steel, including smelting-continuous casting-hot rolling-pickling-cold rolling-annealing-coating-performance inspection-packaging,

[0047]1. The silicon content of molten steel is smelted to 3.1%, and other components are smelted to target components.

[0048] 2. Continuous casting is used to cast molten steel into billets, and the superheat of molten steel is 40°C. A feeding device 1 is added inside the continuous casting crystallizer 5, the inside of the feeding device 1 is a cavity 4, one end of the feeding device 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com