High-efficiency and high-power-density Halbach array brushless direct-current motor

A high power density, brushed DC motor technology, applied to synchronous motors with stationary armatures and rotating magnets, electric components, electrical components, etc., can solve the problem of large iron losses of permanent magnets and rotor yokes, and harmonic content of magnetic fields To achieve the effect of increasing power density, reducing overall weight and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

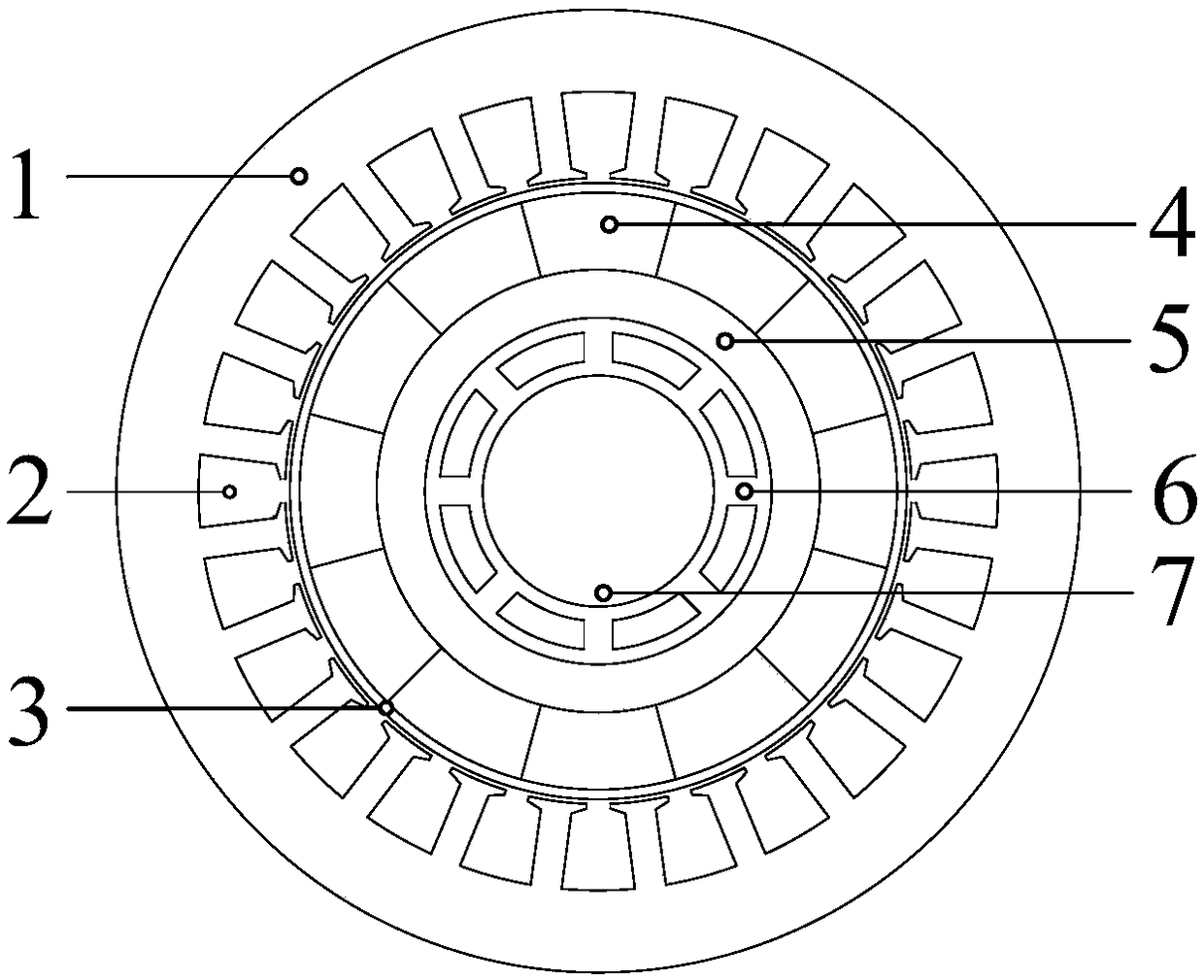

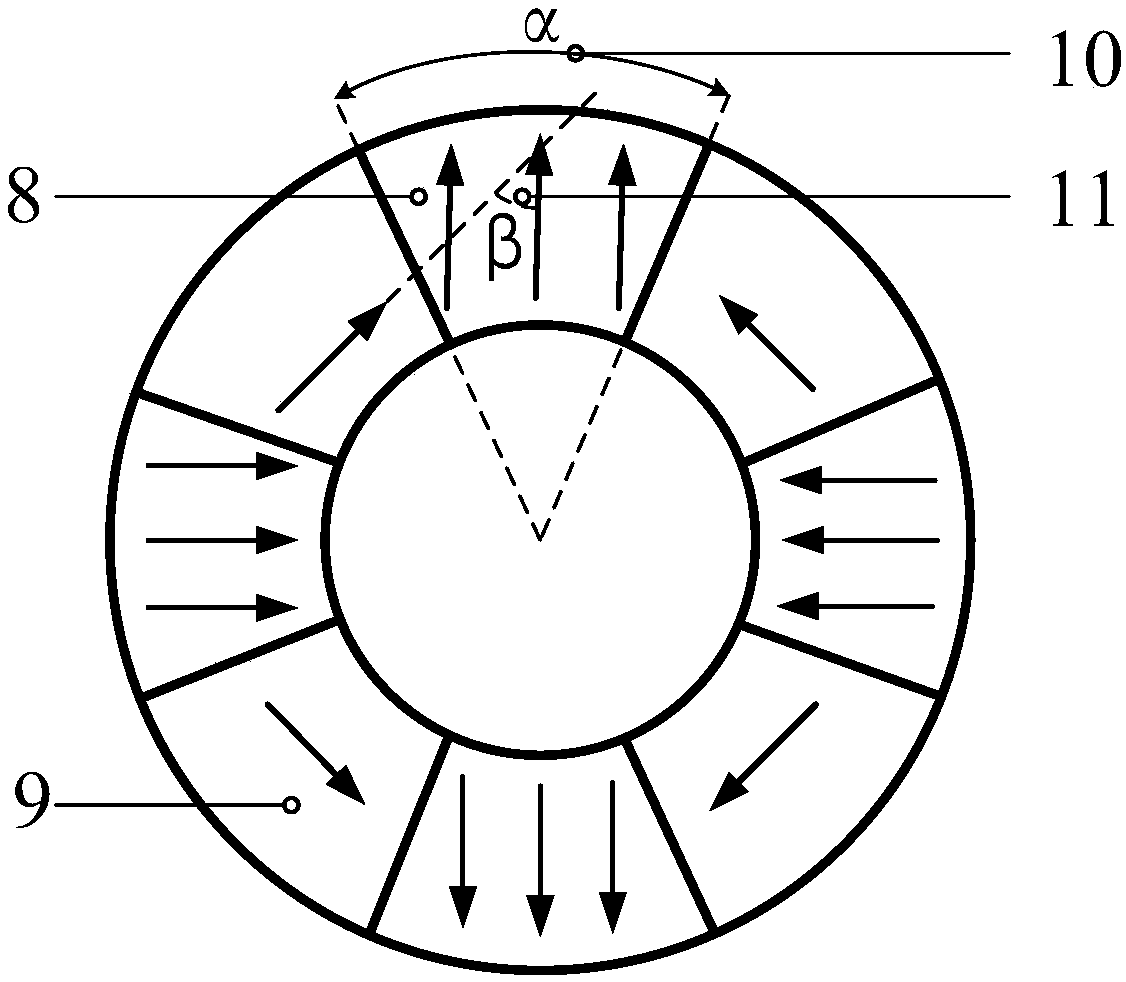

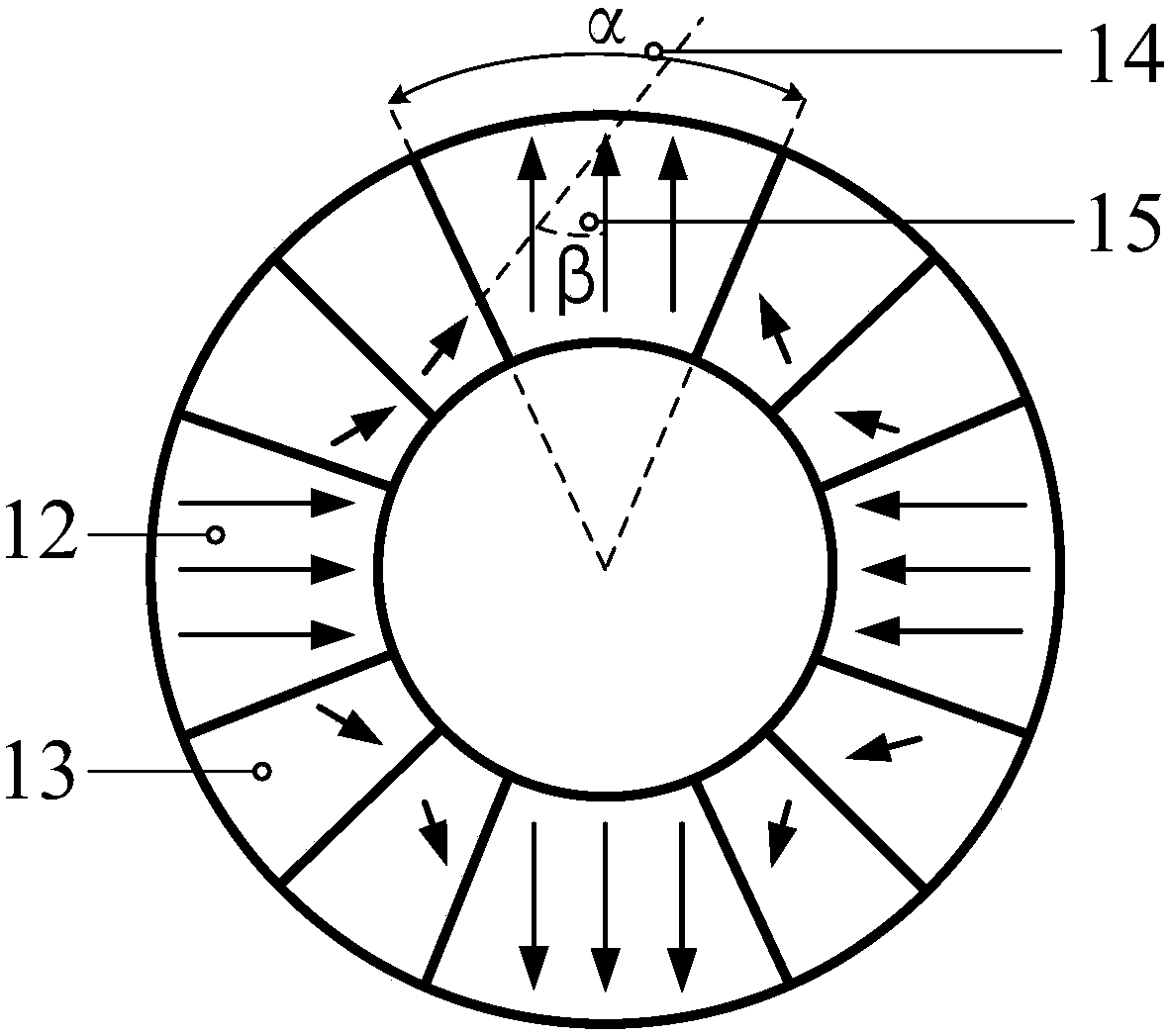

specific Embodiment 1

[0027] The high-efficiency, high-power-density Halbach array brushless DC motor described in this embodiment includes a stator core, an armature winding, a rotor sheath, two permanent magnet Halbach arrays per pole, a yoke, a yoke bracket and a rotating shaft. In this embodiment, the number of stator slots is 24, the number of pole pairs is 2, and there are two Halbach arrays for each pole. The arc angle of the main magnetic steel is 75.6°, the thickness of the yoke is 5mm, and the thickness of the core pad is 6mm. Figure 4 The yoke support is cast aluminum, the thickness of hole 1 in the block is 3mm, and the arc angle is 45°.

specific Embodiment 2

[0028] The high-efficiency, high-power-density Halbach array brushless DC motor described in this embodiment includes a stator core, an armature winding, a rotor sheath, three permanent magnet Halbach arrays per pole, a yoke, a yoke bracket and a rotating shaft. In this embodiment, the number of stator slots is 12, the number of pole pairs is 2, and there are three Halbach arrays for each pole. The block thickness is 6mm, Figure 4 The yoke support is cast aluminum, the thickness of the hole 1 in the block is 3mm, and the arc angle is 45°.

specific Embodiment 3

[0029] The high-efficiency, high-power-density Halbach array brushless DC motor described in this embodiment includes a stator core, an armature winding, a rotor sheath, three permanent magnet Halbach arrays per pole, a yoke, a yoke bracket and a rotating shaft. In this embodiment, the number of stator slots is 24, the number of pole pairs is 2, and each pole has three Halbach arrays. The arc angle of the main magnet is 70°, the magnetization angle of the auxiliary magnet is 32.4°, the thickness of the yoke is 4mm, and the core pad The block thickness is 7mm, Figure 4 The yoke support is cast aluminum, the thickness of the hole 1 in the block is 3mm, and the arc angle is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com