Steel pipe fixing and cutting device

A cutting device and steel pipe technology, applied in the direction of pipe shearing device, shearing device, accessory device of shearing machine, etc., can solve the problems of reducing the service life of the cutting device, hindering the cutting work of the cutting device, and reducing the cutting efficiency, etc., so as to improve the recycling rate. Efficiency, improve cutting efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

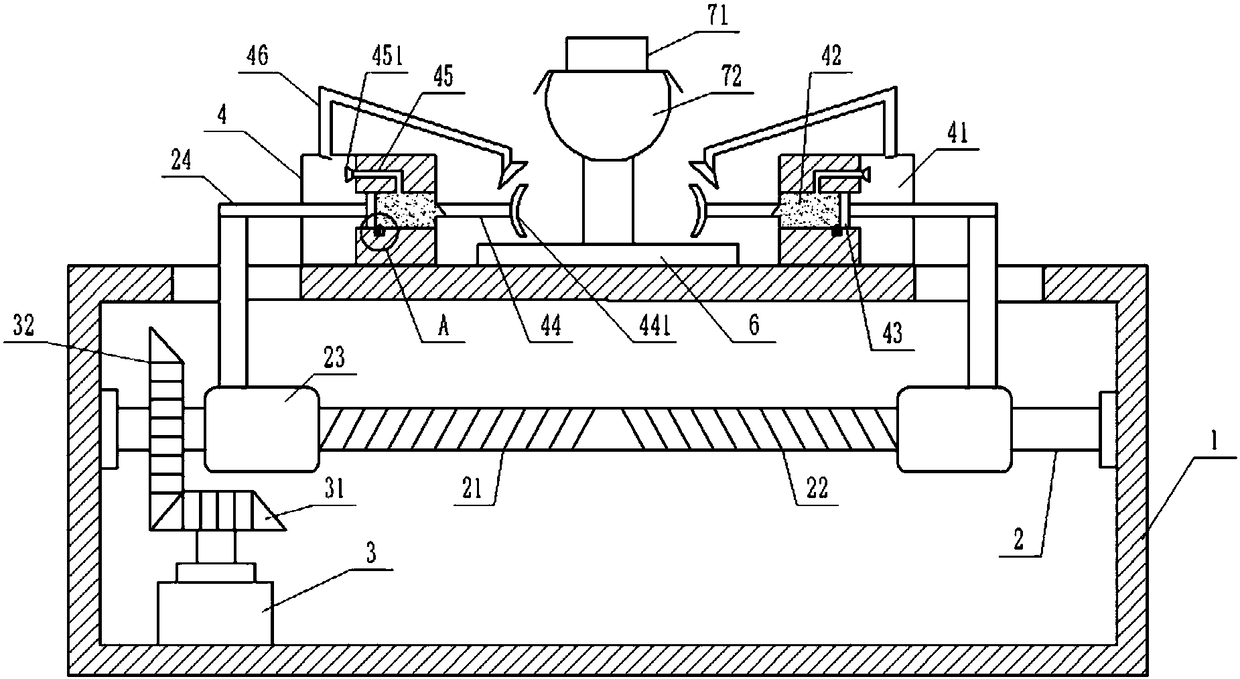

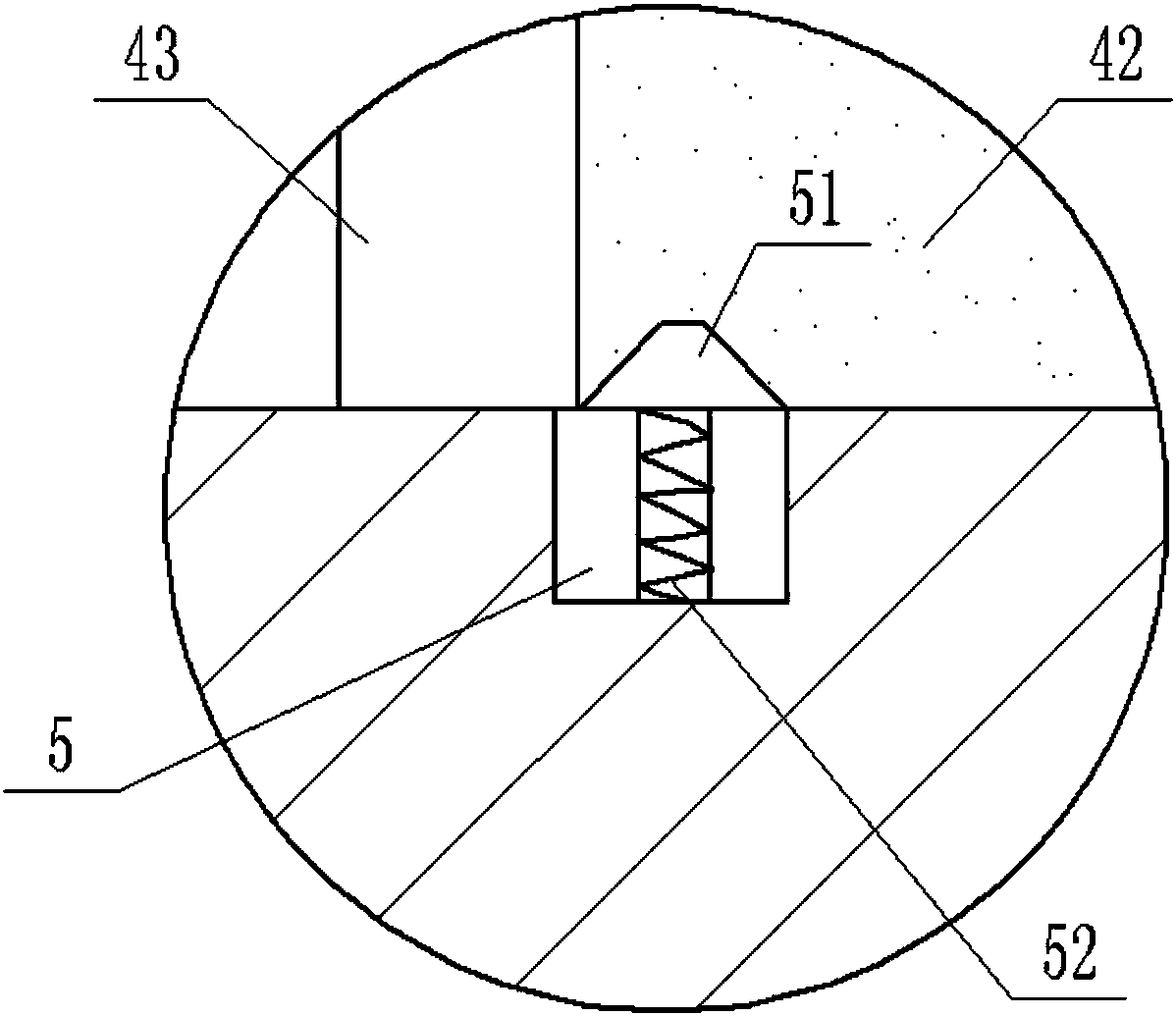

[0020] The reference signs in the drawings of the description include: support frame 1, threaded rod 2, forward thread 21, reverse thread 22, threaded pipe 23, connecting rod 24, motor 3, first bevel gear 31, second bevel gear 32, sliding Box 4, slag collection chamber 41, liquid storage chamber 42, piston 43, fixed pipe 44, clamping piece 441, spray pipe 45, shower 451, slag suction pipe 46, groove 5, bump 51, spring 52, Steel pipe placement platform 6, cylinder 71, cutting tool 72.

[0021] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a steel pipe fixed cutting device, including a cutting mechanism and a steel pipe fixing mechanism, the steel pipe fixing mechanism includes a support frame 1 and a sliding box 4, and the upper end of the support frame 1 is provided with a steel pipe placement platform 6. The cutting mechanism includes a cylinder 71, a cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com